Features and Benefits of Portable Temperature Humidity Chamber

1. LIB Industry portable environmental test chamber boasts a design which ensures not only portability but also durability for frequent use. The chamber is equipped with advanced sensors and control systems that offer precise and fine-tuned adjustments of temperature and humidity.

2. Users can easily transport the mini temperature humidity chamber to different locations, whether it's a field site, a manufacturing facility, or a research laboratory. This flexibility eliminates the constraints of fixed testing environments and enables real-time monitoring and experimentation in various settings.

3. Additionally, the customizable settings allow for tailoring the chamber's conditions to meet the specific requirements of diverse applications, providing a versatile solution for a wide range of industries.

4. The portable thermal chamber's energy-efficient design not only reduces operational costs but also contributes to environmental sustainability. Its user-friendly interface makes it accessible to both novice and experienced operators.

5. Its robust construction and reliable components ensure long-term performance and minimal maintenance, offering a cost-effective investment in the long run.

Specifications of Portable Temperature Humidity Chamber

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

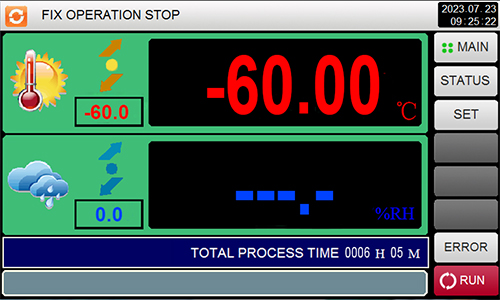

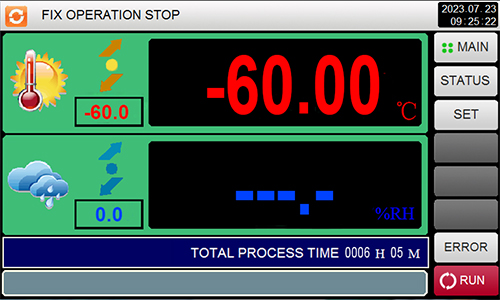

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

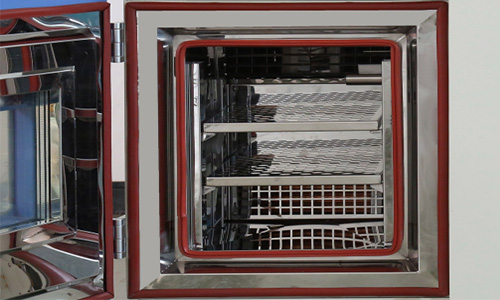

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

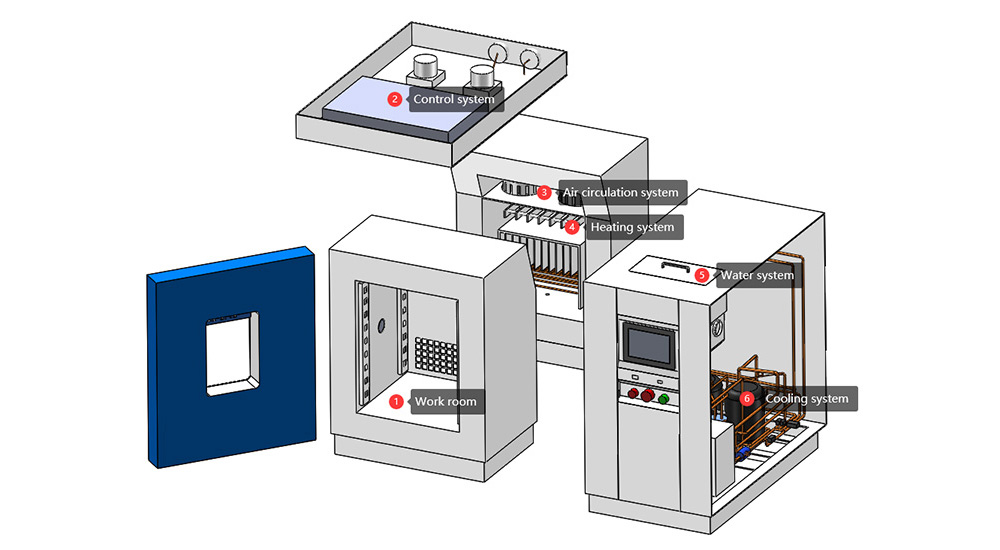

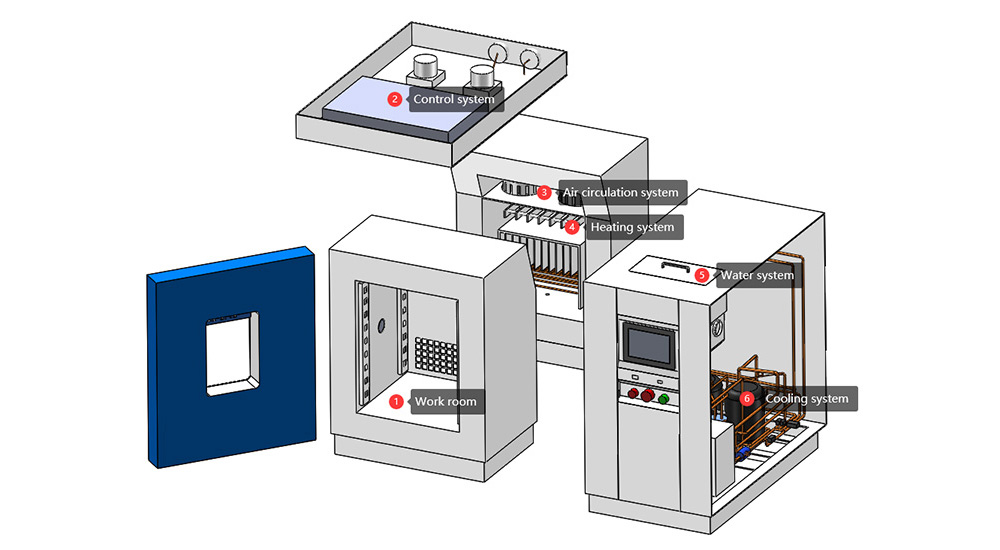

Configuration of Portable Temperature Humidity Chamber

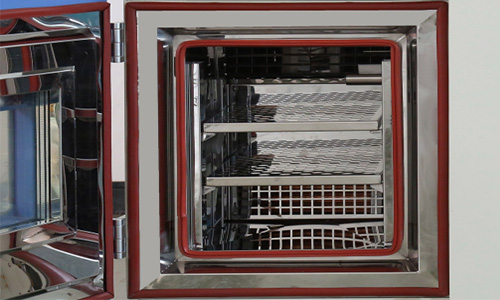

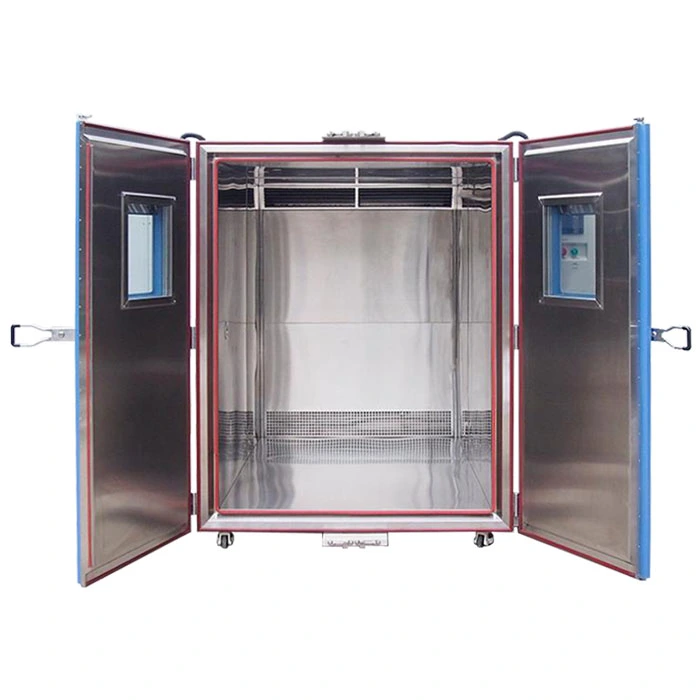

① Workroom | SUS304 stainless steel material, with good corrosion resistance and easy cleaning Sample holder positions can be adjusted according to needs to reasonably place samples of different heights, 50kg load-bearing. φ50mm test cable hole is located ai the left of the workroom.

|  |

② Control system | Programmable color LCD touch screen controller, which can realize the accurate setting, control and monitoring of temperature and humidity, and also has the functions of data display, storage, query and fault alarm.

|  |

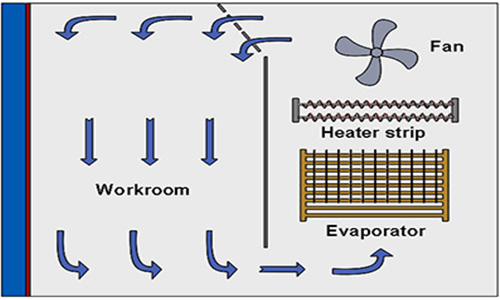

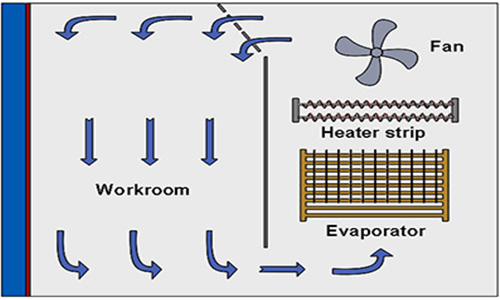

③ Air circulation system | It is composed of fans, air ducts, etc., so that the temperature and humidity are more uniform and ensure the consistency of temperature and humidity in all parts of the chamber. |  |

④ Heating system | composed of heating elements such as heating wire and heating tube, the air in the chamber can be heated according to the set temperature value to reach the required temperature range. |  |

⑤ Water system | Including humidifier, sink and other components, by heating evaporating water to increase the humidity of the air in the chamber. |  |

⑥ Cooling system | The use of mechanical compression refrigeration system, through the compressor, condenser, evaporator and other components work together to achieve the reduction of temperature in the chamber. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español