The Application of IP67 Test Equipment

The IP67 test equipment can usually simulate water depth, water pressure, soaking time, water temperature and other conditions, and carry out a series of strict waterproof performance tests on the tested product to determine whether it meets the requirements of the IP67 protection level. This ip67 test equipment is widely used in electronic, electrical, automotive, communication and other industries, for testing the waterproof performance of various products such as mobile phones, cameras, sensors, lamps, etc., to ensure that products can still work normally in harsh water environments.

Features and Benefits of - IP6X dust test equipment

1. The ip6x test equipment can accurately generate and control the dust concentration and particle size that meet the requirements of the standard, ensuring the accuracy and consistency of the test conditions.

2. The ip6x test equipment adopts a concatenated design, silicone strip to increase the sealing, equipped with electromagnetic lock, multi-layer sealing device to ensure that dust will not leak to the external environment due to misoperation or other reasons during the test process, polluting the working environment, while preventing external air from entering the test results.

3. The ip6x test equipment is equipped with an efficient dust circulation and stirring system, so that the dust is evenly distributed in the test equipment , and the dust is circulated vertically to ensure that all parts of the tested sample can be fully exposed to the dust environment. It has a stable airflow control device that can maintain a constant airflow speed to simulate a real dust environment.

4. The ip6x test equipment has a large area of transparent observation window, which is convenient to observe the status of the sample in real time during the test process, without affecting the tightness of the test equipment . Observation window equipped with wiper, which can remove the dust from the window.

Specifications of IP67 Test Equipment - IP6X dust test equipment

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

Features and Benefits of - IPX7 water immersion test equipment

1. The ipx7 test equipment can accurately simulate the environment in a water depth of 1 meter, and meet the standard requirements by adjusting the water level and pressure. The ipx7test equipment reproduces water depths of 1-50m with pressure up to 50bar.

2. The internal design of ipx7test equipment is reasonable to ensure that all parts of the tested sample can be subjected to uniform water pressure and water flow during the soaking process. ipx7test tank is equipped with built-in sample holder whose maximum load 50 kg, and the height is adjustable.

3. ipx7test equipment is equipped with high-strength manual pressure locks.The number of lock can be customized. Meanwhile it has pneumatic bar,which is controlled by the controller, realizing the function of opening/closing the cover with one button.

4. The controller of the ipx7test equipment can accurately set and control the soaking time, from a few minutes to a few hours, to meet different test needs.

5. ipx7test equipment’s material is made of SUS304, with good sealing and durability, rust and corrosion resistance, strong robustness.

Specifications of IP67 Test Equipment - IPX7 water immersion test equipment

Model | R78-600 |

Internal Dimensions (mm) | Diameter600*Height1500 |

Overall Dimensions (mm) | Diameter800*Height1800 |

Pressure | 50m water depth pressure |

Open Mode | Pneumatic lid |

Material | A3 steel plate,wall thickness 15mm |

Water Supply System | Storage water tank,Automatic water supply |

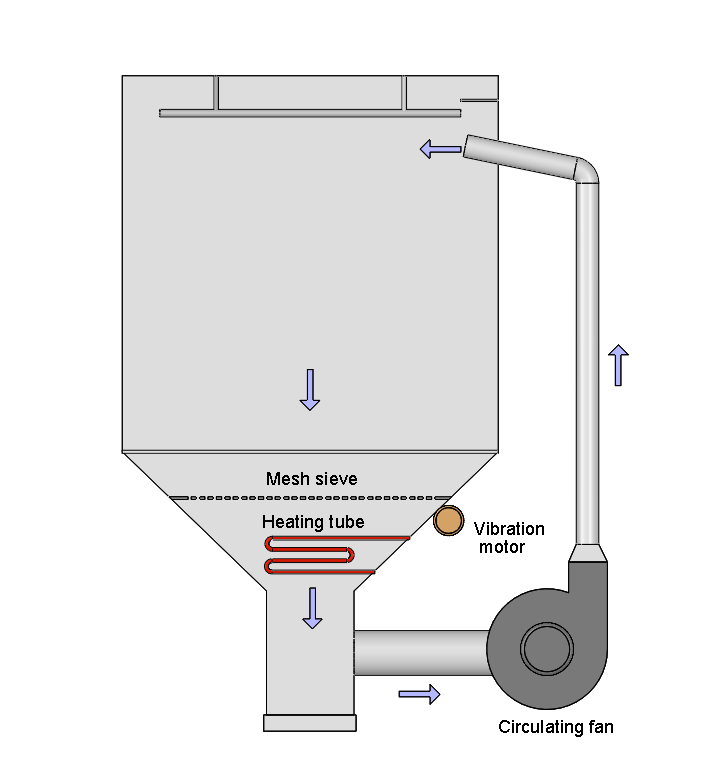

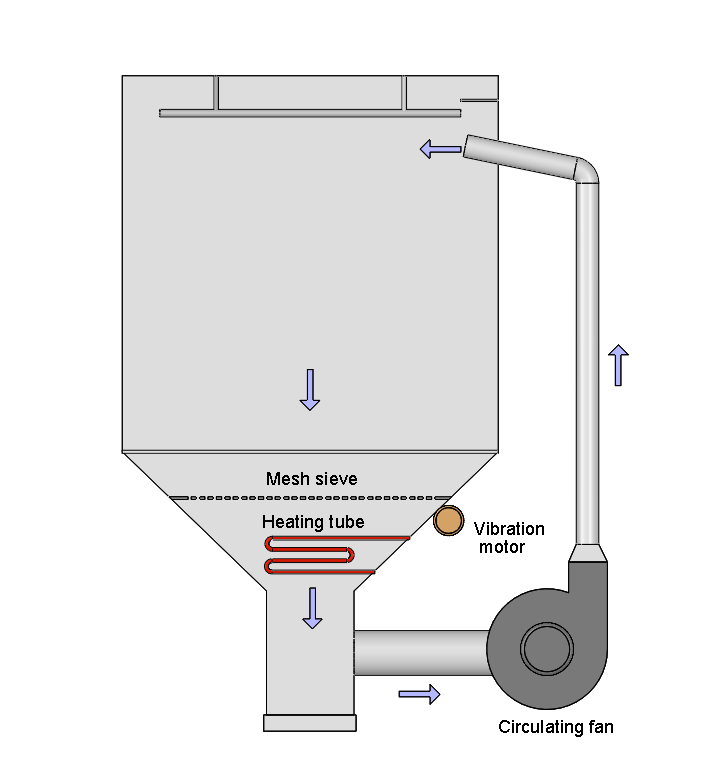

Working Principle of IP6X Test Equipment

The ip6x test equipment is mainly used to test the dustproof performance of the product. Its working principle is based on simulating a dusty environment and seeing if the dust can enter the inside of the product being tested.

First, the sample to be tested is placed on a turntable in the test equipment, a power supply is provided on the turntable. Then, dust is generated through the dust outlet, which is usually particles that meet the requirements of the standard, such as talc,The diameter of the mesh hole is 75 μm.

The fan in the air duct system blows dust into the inside of the ip6x test equipment to form a uniform dust environment. By controlling the speed and air volume of the fan, the distribution and concentration of dust in the equipment can be adjusted. The dust is passed through a vertical air discharge system, which circulates in the studio and air duct throughout the test process.

During the test, the test equipment is kept sealed to prevent outside air from interfering with the test results. After the specified test time, the sample is taken out and checked for dust inside.

To determine whether the sample meets the ip6x dust class standard, the main basis is that under the specified test conditions, there is no visible dust intrusion inside the sample.

Working Principle of IPX7 Test Equipment

The ipx7 test equipment is used to evaluate the water resistance of the product when submerged at a certain depth for a short period of time.When working, first install the sample firmly on the sample shelf in the test equipment . Then, water is injected into the tank through the water level control system, so that the water level gradually rises to the specified depth of 1 meter.

During sample soaking, the water pressure is maintained to ensure that all parts of the sample are subject to uniform pressure.After the soaking time, the sample is removed from the water to check whether there is water inside the sample.

The key to judging whether the sample meets the ipx7 waterproof grade is that there is no water infiltration inside the sample and the function is normal within the specified 1 meter water depth and soaking time.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español