Heat Cold Moisture Chamber Features and Benefits

1.Efficient cooling and heating systems, rapid cooling and heating can be achieved, shortening the test cycle. The heating rate of some advanced test chambers can reach 3℃/min or more, and the cooling rate can reach 1℃/min.

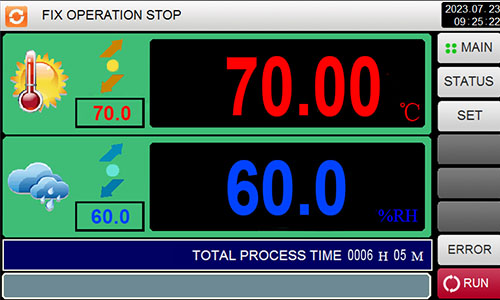

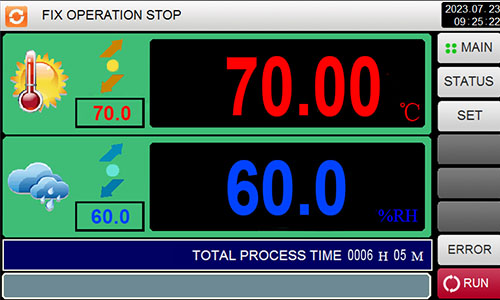

2. Temperature control accuracy can reach ±0.5℃, humidity control accuracy maintain at ±2.5%RH, temperature and humidity control range is wide, can test the product in extreme hot and cold, dry or high humidity environment.

3. Solid structure, refrigeration, heating, humidification and other key system performance is stable, can be long-term stable operation, to ensure the continuity and stability of the test process, for product durability testing, etc.

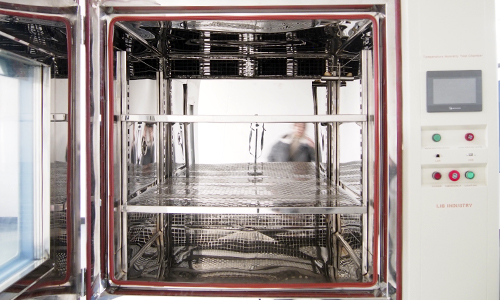

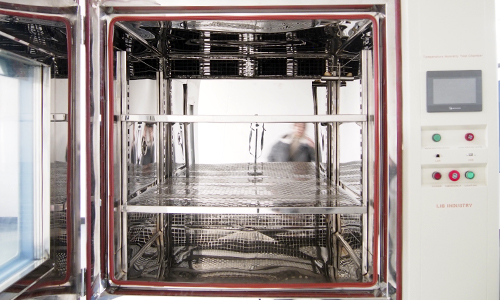

4. Equipped with observation window, convenient observation of sample status. The left side of the workroom is equipped with a test interface, which can test the electrical properties and other aspects of the sample.

Heat Cold Moisture Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

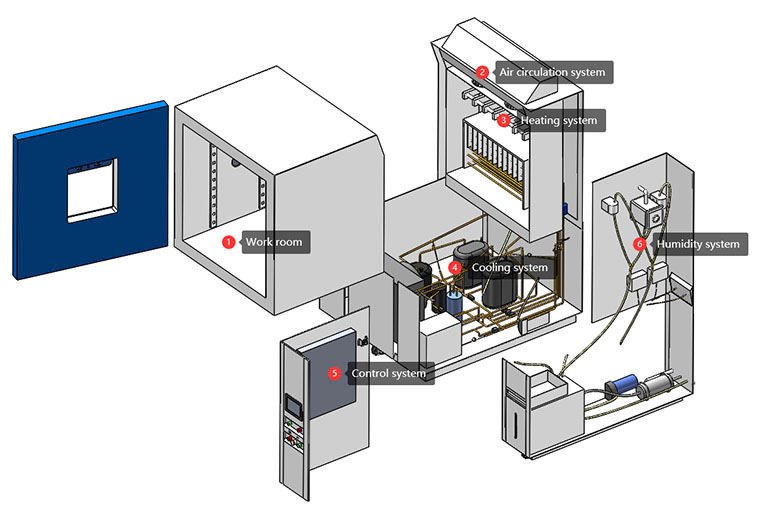

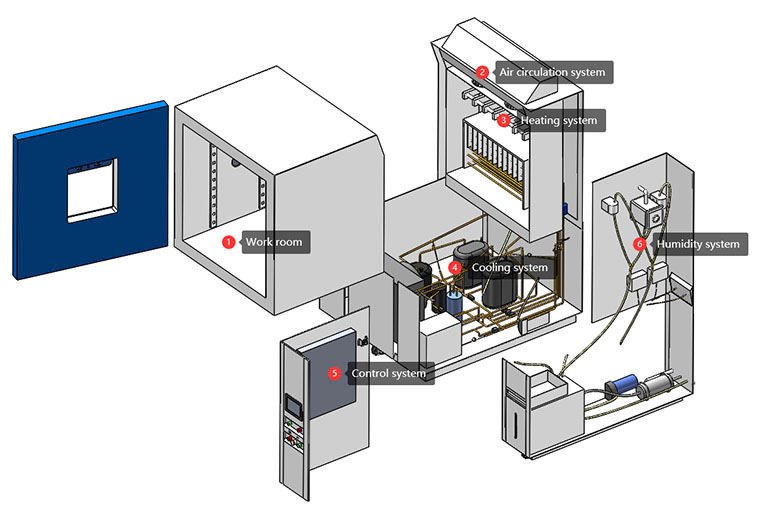

Configuration of Heat Cold Moisture Chamber

① Workroom | External material is made of A3 steel plate, the inner wall of the workroom adopts SUS304 mirror stainless steel panel, which has good corrosion resistance and thermal conductivity, easy to clean and maintain. PT-100 Class A sensor, accuracy at 0.001 degrees. A wet gauze and a real-time temperature, converted by temperature difference, showing real-time relative humidity. Punching sample shelf 2pcs.

|  |

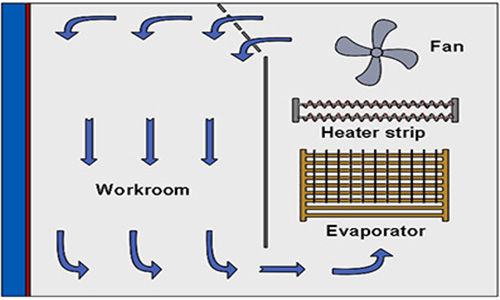

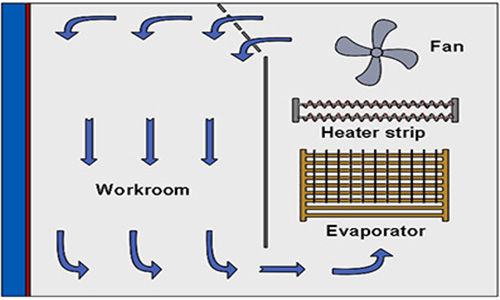

② Air circulation system | Centrifugal fan is used to circulate the air inside the test chamber so that the temperature and humidity inside the chamber are evenly distributed. |  |

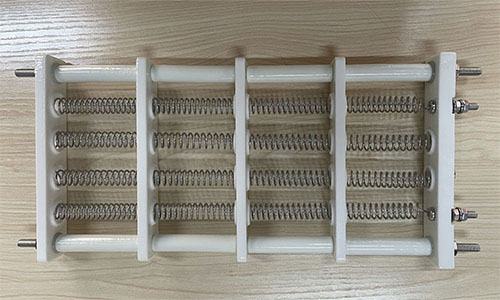

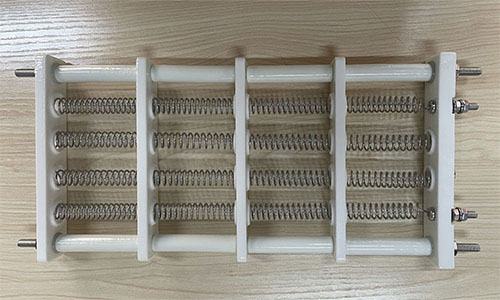

③ Heating system | Composed of high-power resistance wires and can generate heat quickly. |  |

④ Cooling system | The use of mechanical refrigeration, including the core components of the refrigeration system compressor, condenser, throttle mechanism, evaporator. |  |

⑤ Control system | PID control can control and adjust the temperature, humidity, air circulation and other parameters of the test chamber through the operation panel. |  |

⑥ Humidity system | Steam humidifies, evaporates to increase humidity. Humidifiers need to have good control accuracy. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español