Rapid Rate Thermal Cycling Chamber Features and Benefits

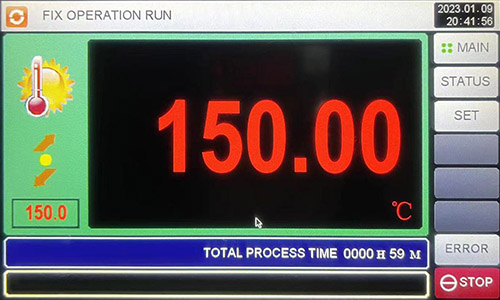

1. Fast temperature change rate: it can achieve a large temperature rise and fall in a short time, the rate is generally 5℃/min, 10℃/min, 15℃/min, and a faster heating rate can be customized under special circumstances.

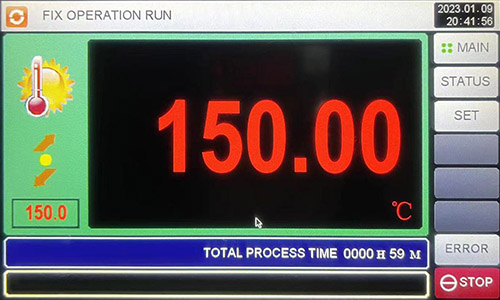

2. The temperature range is -70 ° C to 150 ° C, which can meet the test needs of a variety of products, and the temperature range can be customized.

3. Humidity system can be installed , perform rapid temperature change, condensation test, high temperature and humidity, temperature and humidity cycle and other test functions.

4. The use of advanced temperature sensors and control systems can ensure the accuracy and stability of temperature control, so as to ensure the accuracy and reliability of test data.

Rapid Rate Thermal Cycling Chamber Specifications

Model | TR5-100 | TR5-225 | TR5-500 | TR5-800 | TR5-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 5 ℃ / min |

Heating Rate | 5 ℃ / min |

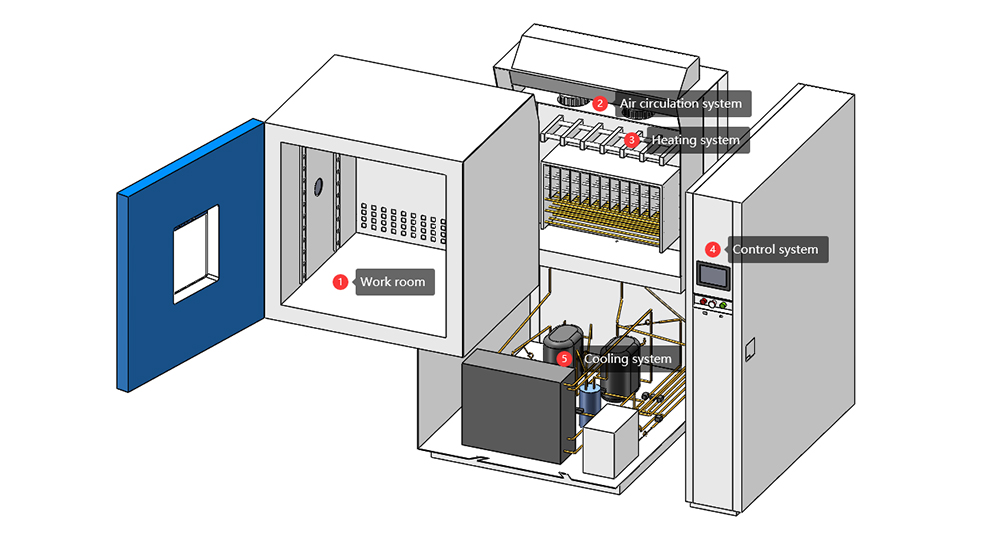

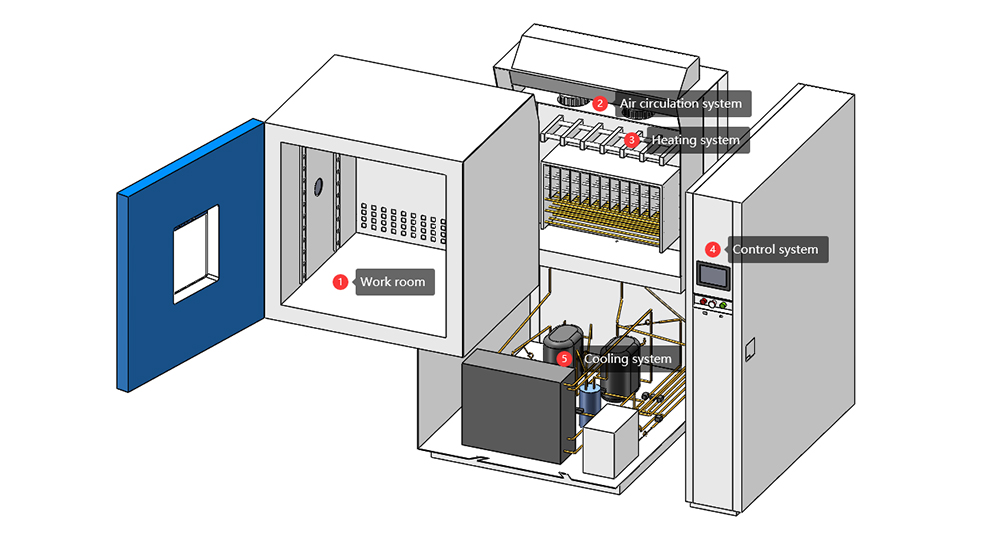

Configuration of Rapid Rate Thermal Cycling Chamber

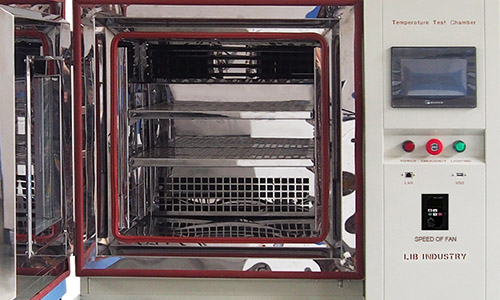

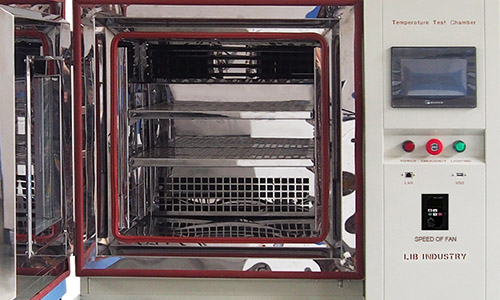

① Workroom | The inside is SUS304 stainless steel plate, high and low temperature corrosion resistance, 10mm insulation material to ensure stable temperature inside the chamber. A test cable is provided on the side of the chamber. Equipped with high precision temperature sensor.

|  |

② Control system

| PID touch temperature controller, can set the program and parameters, but also real-time display of test data and operating status. |  |

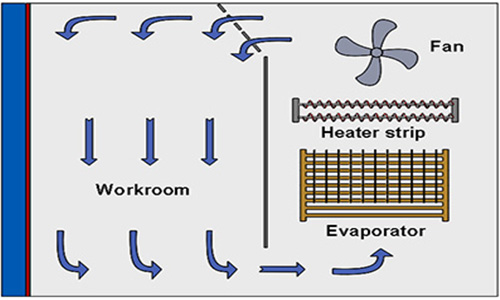

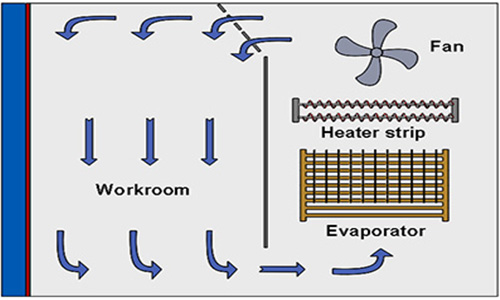

③ Air circulation system | Composed of fan, air exchange port and exhaust port, etc., which can circulate the air in the chamber to ensure uniform distribution of temperature. |  |

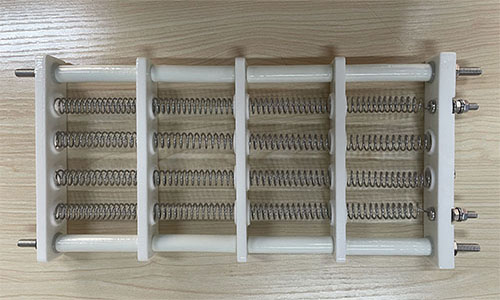

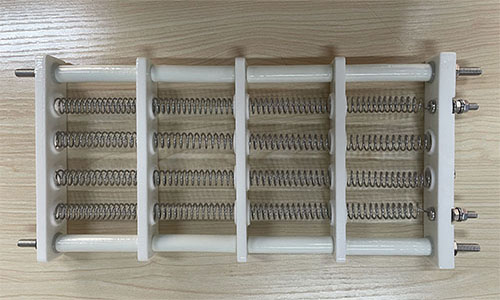

④ Heating system

| Composed of heating wire, by generating heat to increase the temperature in the test chamber. |  |

⑤ Refrigeration system

| The use of cascade air-cooled refrigeration system, including high temperature refrigeration cycle and low temperature refrigeration cycle, quickly reduce the temperature in the workroom. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español