Paints can be seen everywhere in our daily life, paints is also the first solid barrier for many products, and its quality is related to the quality and life of the product. The most important aspect of paints performance is its weather resistance. The LIB xenon test chamber takes you to restore the sun, rain and temperature changes experienced by the paints in daily life.

Traditional weathering methods include Florida or Arizona adopt outside exposure with very long time to get result, 1 year, 5 year, 10 year... , also includes natural sun tracing and exposure device, also it takes long time, complex, troublesome to get result.

And now, the LIB xenon test chamber has greatly accelerated those traditional aging ways to test the weather resistance of paint, how is this done?

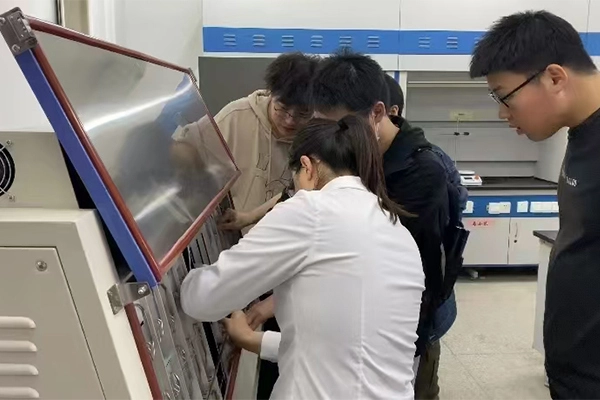

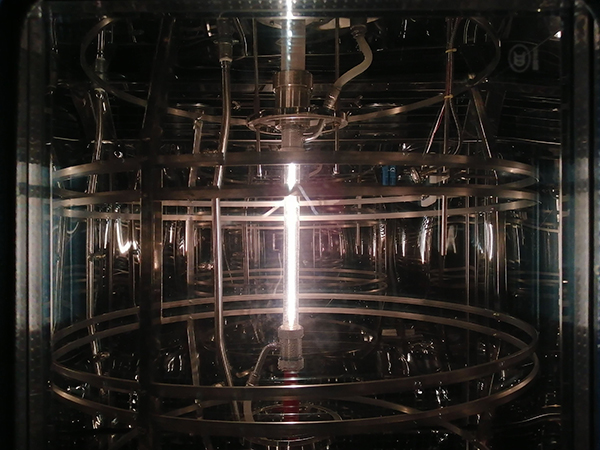

First of all, there are two kinds of LIB xenon test chamber, one is a flat shelf type, and the other is a rotating drum holder type. The rotating drum shelf is generally used to test the paint, because the rotating drum shelf can accommodate three layers of paint measurements at the same time, with a maximum capacity of 42 pieces, of course, the size of the sample shelf can also be customized, greatly improving the test efficiency and the comparability of different paint measurements, while the rotating shelf ensures the balance and consistency of the accepted light source.

The core of xenon lamp aging test chamber is that it can produce xenon arc light source with high spectral similarity to the sun. The light from the xenon lamp carries ultraviolet, visible and infrared rays and shines precisely on the paint template. The organic components in the paint are "catalyzed" by ultraviolet light, and the chemical bonds begin to break and recombine. This causes the pigment to fade, the polymer chain to degrade, and then the color of the paint gradually dimmer, the luster quietly fades, and eventually there may be a powdering phenomenon, like the mottled traces of age on the surface of the paint.

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

| |

In addition to light, the paint will also be subject to temperature and humidity changes, and some rain scenes. The LIB xenon test chamber is equipped with a highly accurate temperature and humidity control system, which creates a variety of complex temperature and humidity environment combinations. The high temperature will accelerate the chemical reaction rate inside the paint, making the molecular movement more active; In the high humidity environment, water vapor molecules quietly penetrate into the microscopic pores of the paint and react with the components such as hydrolysis, which weakens the structural integrity of the paint. When light, high temperature and high humidity are combined, the speed of paint aging increases exponentially, and the aging effect of outdoor years can be simulated in just a few weeks or even a few days.

The spray system in the LIB xenon test chamber adds a more realistic touch to the paint test. Intermittent spraying is like a summer rainstorm raid, water droplets impact the paint surface, not only to test its water resistance, but also in the process of dry and wet alternating, so that the paint due to expansion and contraction of internal stress, accelerate the paints peeling and choldering. This way of simulating natural precipitation and dew allows the paint to show the advantages and disadvantages of its weather resistance in an all-round way in the cyclic "baptism".

The key to improving paint quality lies in accurate testing. LIB xenon lamp aging test chamber has excellent lighting simulation, temperature and humidity control and spray functions to quickly show the whole process of paint aging. This is not only a piece of equipment, but also your paints research and development and quality assurance partner, to help you seize the market opportunity. Contact us inquiry@libtestchamber.com for xenon test chamber solutions and best quote.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español