Features and Benefits of PV Degradation Testing Chamber

1. The humidity can be adjusted in the range of 20%-98%, the temperature can generally reach -60 ° C to 100 ° C, and the wet freezing test can be set in the relative humidity of 85% and the temperature of -40 ° C.

2. In addition to the conventional wet freezing test, it can also be done such as wet heat, heat cycle test.

3. On the basis of the standard PV degradation testing chamber, the functions of salt spray and rain can be customized, so that a variety of aging tests can be carried out in the same equipment.

4. Multiple wet-freezing cycles can be completed in a short time, and multiple photovoltaic panels can be placed at a time to accelerate the aging process of photovoltaic modules.

Specifications of PV Degradation Testing Chamber

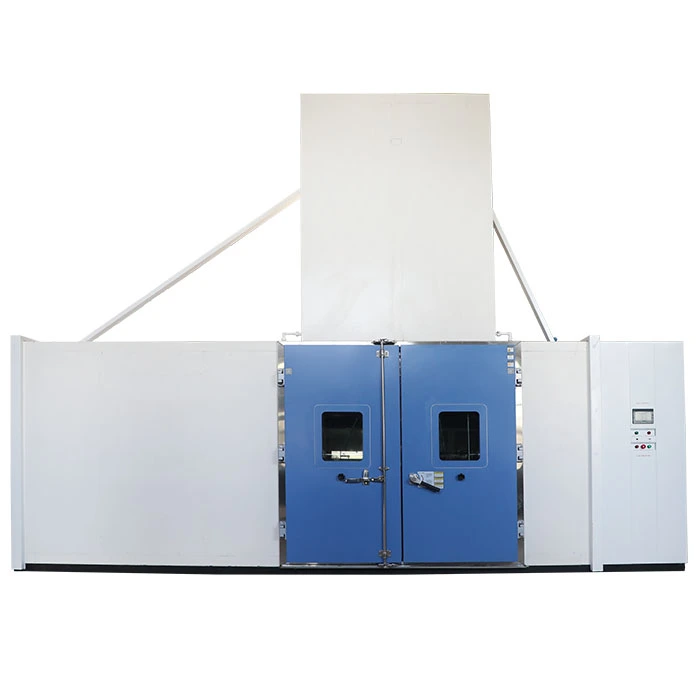

Model | PV-04 |

Internal Dimension (mm) | 1300*700*1350 |

Overall Dimension (mm) | 1900*1100*1750 |

Interior Volume | 1220L |

Parameter | Temperature Range | -60℃ ~ +100 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Temperature Change Rate | 1 ~ 3.4℃ / Min |

Panel Size | 1M*2M |

Panel Capacity | 4 / 6 / 8 / 10 / 12 Pieces |

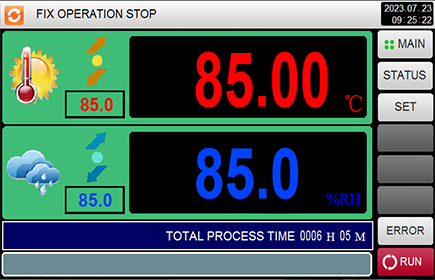

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB |

Humidity | Water supply system | Automatic water supply |

Water supply system | Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Dehumidification | Evaporator |

Sensor | Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class, accuracy 0.001℃ |

Humidity Sensor | Dry and wet bulb sensor |

Build-in Water Tank(mm) | 270*300*450 |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure Protection; Water Shortage Protection; Earth leakage Protection |

Details of PV Degradation Testing Chamber

Application of PV Degradation Testing Chamber

By simulating the harsh wet and freezing environment, the most suitable materials are accurately selected. Silicon, glass, film and other raw materials need to be tested by wet freezing test. Monitor key indicators such as power attenuation and insulation performance changes of photovoltaic panels, and carry out wet-freezing tests in accordance with international standards such as IEC 61215.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español