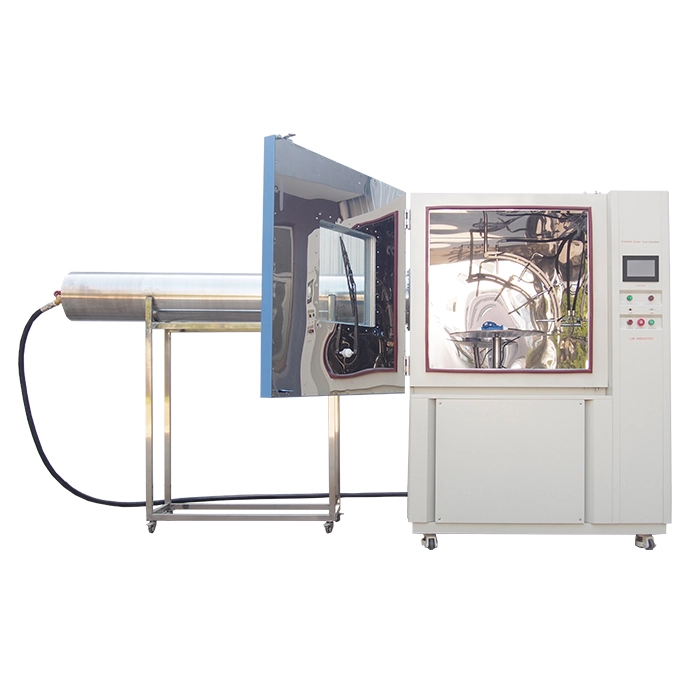

Features and Benefits of IP6K9K Test Machine

1. Simulate the water situation in severe weather such as heavy rain, and verify the protection ability of the product under high temperature and high pressure water injection.

2. Accurate water pressure and water flow control, can produce stable and meet the standard requirements of high water pressure, the general water pressure between 8000-10000kPa, water flow control at 14-16L/min.

3. The strong housing 4MM A3 steel and stable structure design can withstand the impact of high pressure spray impact and possible vibration during the test process, so as to ensure the stable performance of the equipment during long-term use.

4. IP6K9K test machine to achieve automatic operation, the user only need to place the sample on the test platform and set the test parameters, the equipment can automatically complete the test process.

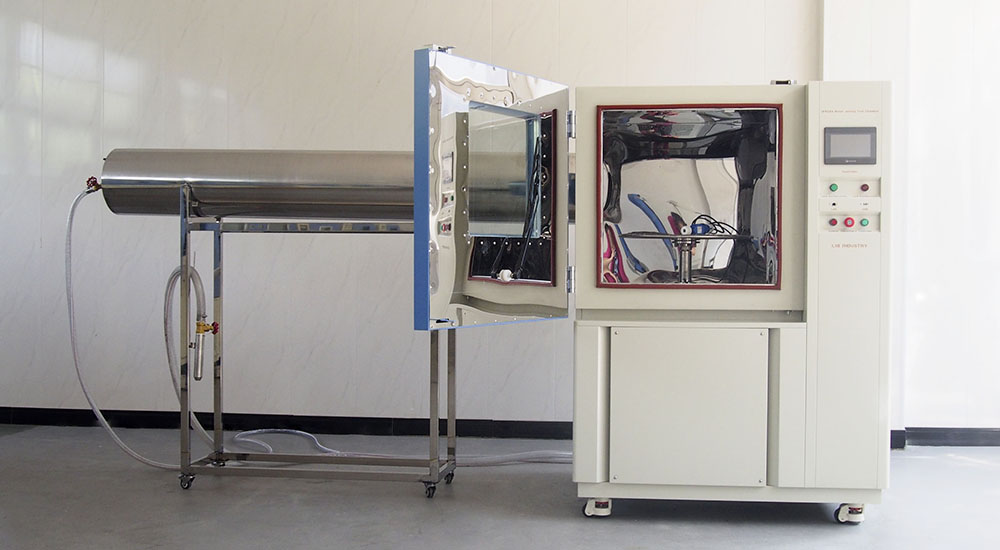

Specifications of IP6K9K Test Machine

Model | R6K9K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance from Water Spraying to Specimens | between 2.5 m and 3 m. |

IPX9K | Water Spray Angle | 0°, 30°, 60°, 90° |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance from Water Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class |

Heater Elements | Nichrome heater |

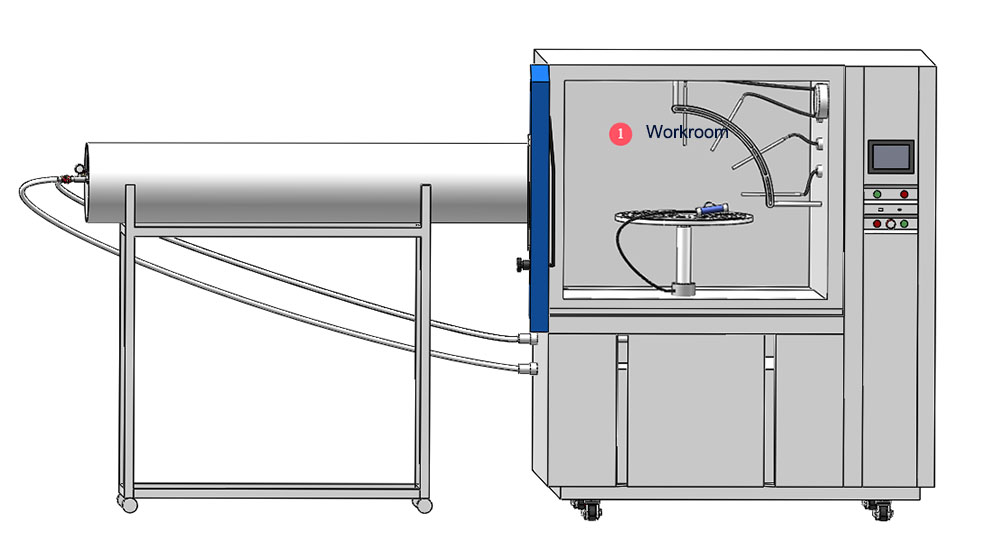

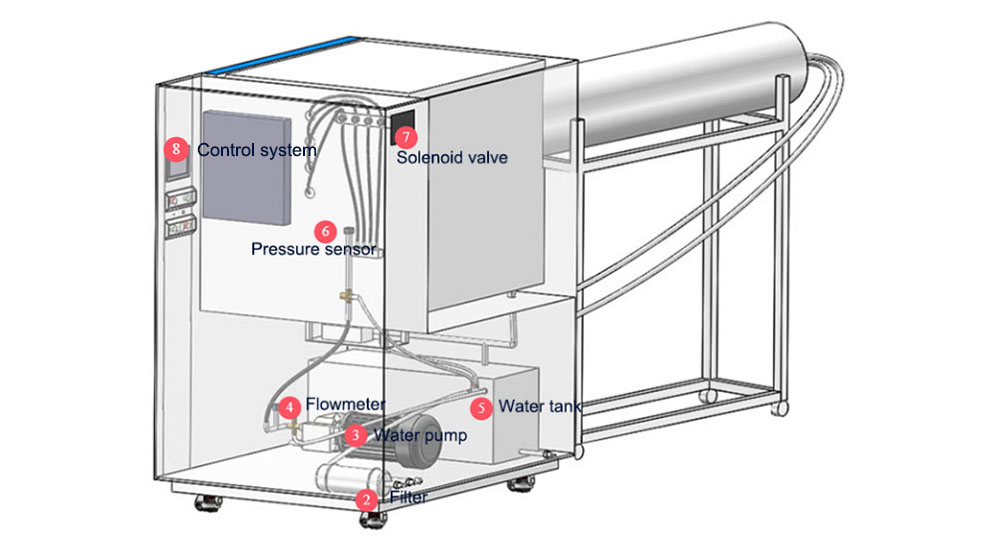

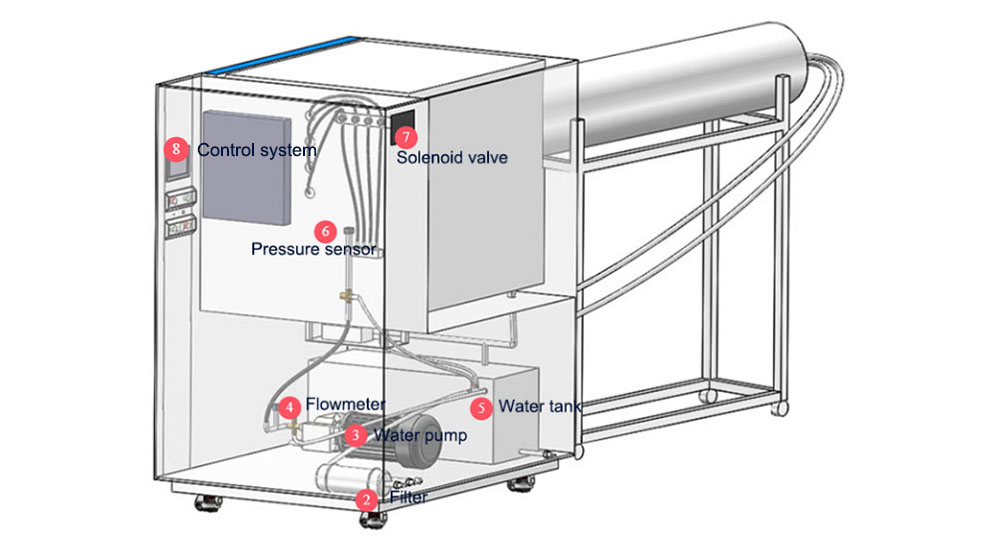

Configuration of IP6K9K Test Machine

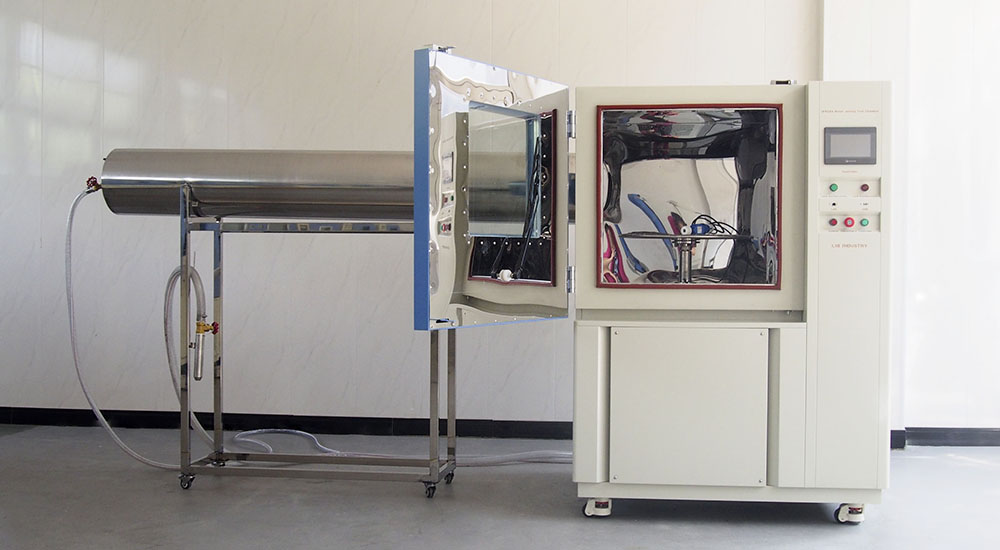

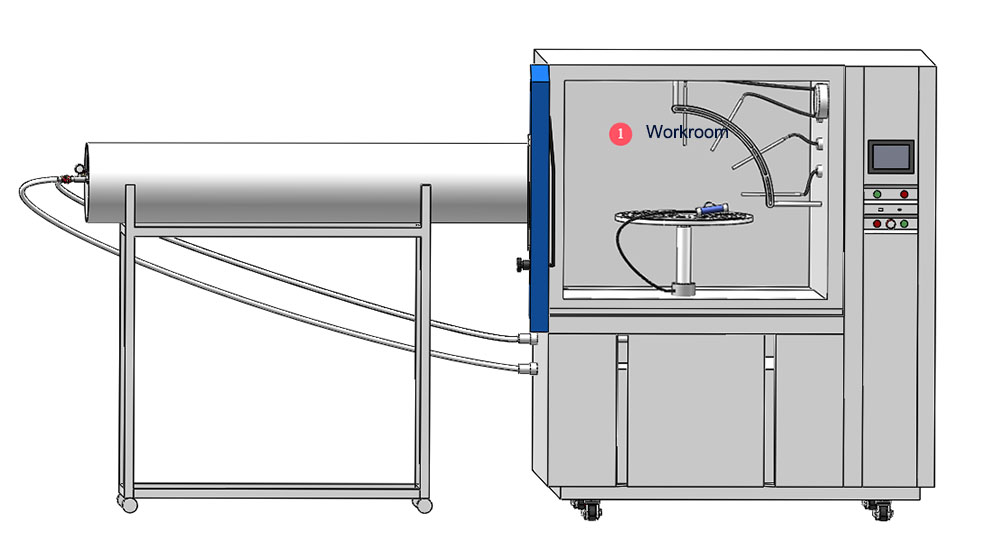

① Workroom | made of SUS304 stainless steel plate, which has good corrosion resistance and prevents rust. The 6K nozzle with 12.5mm diameter to produce a strong spray is located on the left side of the pipe, and the 9K nozzle is located inside the workroom with 4 spray angles 0°, 30°, 60°, 90°.The nozzles are made of stainless steel to prevent rust. The turntable is equipped with waterproof power supply The rotating speed and height of the sample turntable are adjustable.

|  |

② Filter | Water filtration and circulation unit,filter impurities from 0.03mm particles. |  |

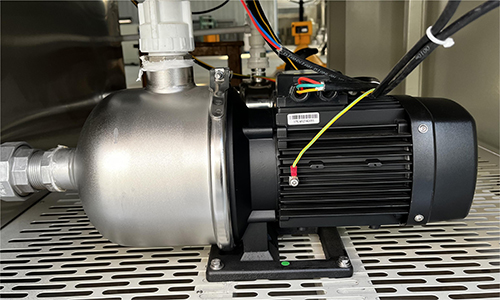

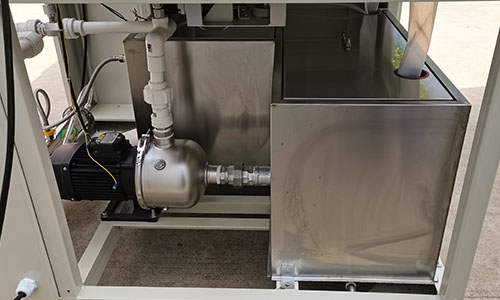

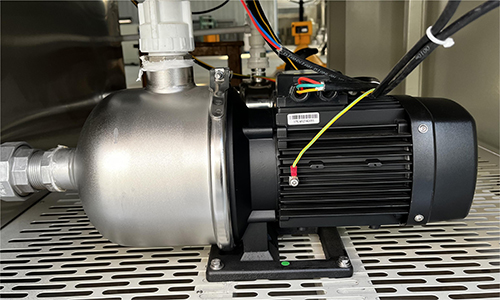

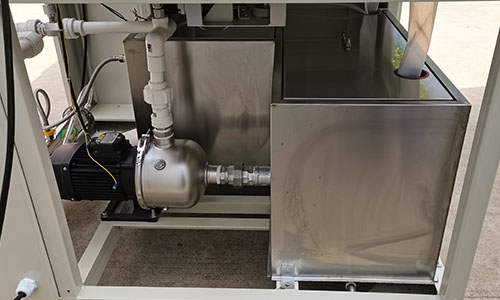

③ Water pump | Power the water spray so that the water can be ejected from the nozzle with sufficient pressure. |  |

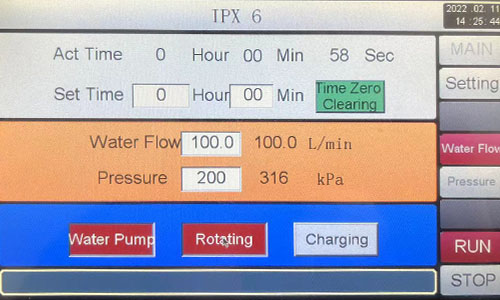

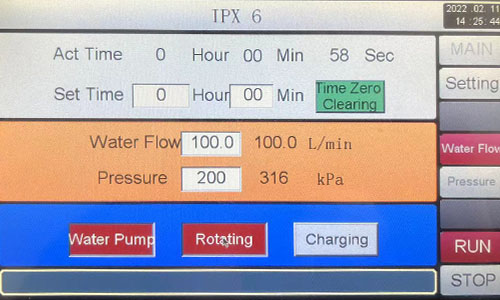

④ Flow meter | Measure the water flow rate to ensure that the spray flow rate meets the requirements of 100±5 (L/min) IPX6 and 14~16L/min IPX9K. |  |

⑤ Water tank | Store test water, the use of liquid level sensors, real-time monitoring of the water level in the tank |  |

⑥ Pressure sensor | Accurately measure the pressure value, the pressure probe has strong resistance to high pressure. |  |

⑦ Solenoid valve | The solenoid valve can quickly and accurately respond to the instructions of the control system and control the flow of water. |  |

⑧ Control system | Touch screen control panel, convenient for users to set test parameters (such as spray time, water temperature, turntable speed, etc.), start and stop the test, view the test results. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español