Features and Benefits of PV Environmental Chamber

1. As one of trusted and professional environmental chamber manufacturers, LIB Industry PV Environmental Test Chamber featuring precise temperature regulation over a wide temperature range (from -60 low to high temperatures) with small temperature deviations ±2℃ in large workroom. Accurately control humidity levels with 2.to simulate a variety of wet or dry environments.

2. Multiple or different batches of PV products are tested to facilitate comparative analysis and help screen out products with better performance and more reliable quality.

3. The use of advanced thermal insulation technology and energy-saving design can effectively reduce the energy consumption of equipment and reduce energy waste.

4. In addition to temperature and humidity, other environmental factors can be customized such as light, rain, wind speed, salt spray, etc. These environmental factors can be added individually or can be combined to control.

Specifications of PV Environmental Chamber

Model | PV-04 |

Internal Dimension (mm) | 1300*700*1350 |

Overall Dimension (mm) | 1900*1100*1750 |

Interior Volume | 1220L |

Parameter | Temperature Range | -60℃ ~ +100 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Temperature Change Rate | 1 ~ 3.4℃ / Min |

Panel Size | 1M*2M |

Panel Capacity | 4 / 6 / 8 / 10 / 12 Pieces |

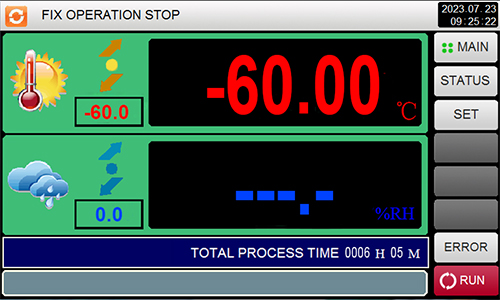

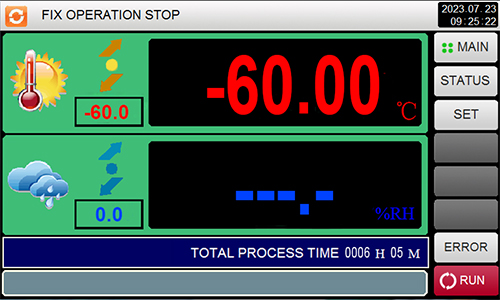

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB |

Humidity | Water supply system | Automatic water supply |

Water supply system | Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Dehumidification | Evaporator |

Sensor | Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class, accuracy 0.001℃ |

Humidity Sensor | Dry and wet bulb sensor |

Build-in Water Tank(mm) | 270*300*450 |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure Protection; Water Shortage Protection; Earth leakage Protection |

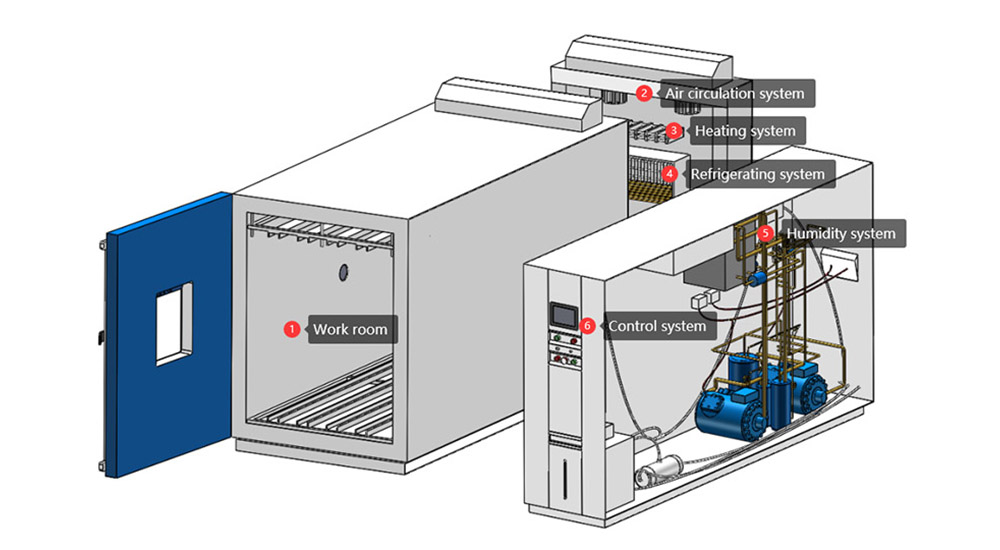

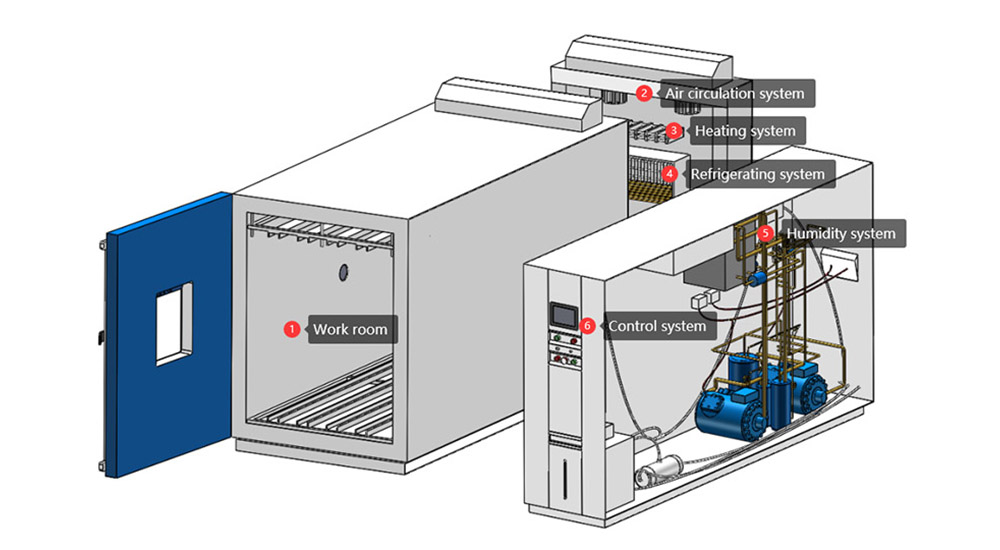

Configuration of PV Environmental Chamber

①Workroom | The internal material is 304 stainless steel, workroom is designed for panels up to 1.2m. The sample holder can be adjusted, such as adjusting the distance and angle of the sample rack, to meet the test needs of different specifications of PV modules.

|  |

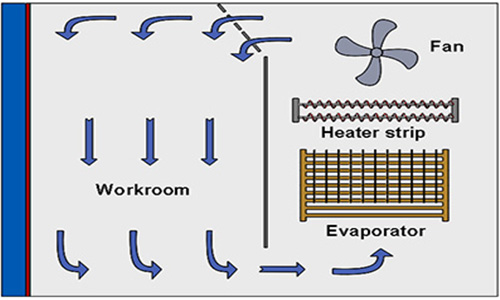

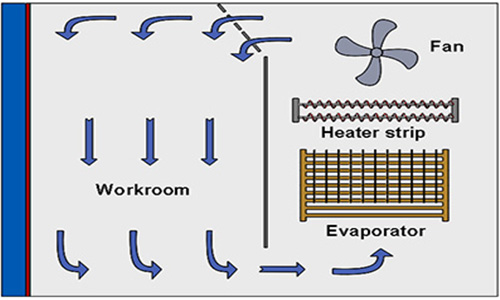

②Air circulation system | The fan provides the power to circulate the air in the air duct to ensure the uniform flow of air inside the workroom, so that the temperature, humidity, and other environmental parameters are evenly distributed. |

|

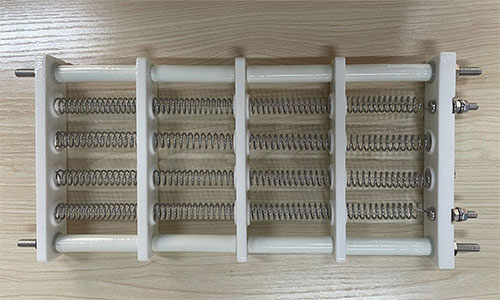

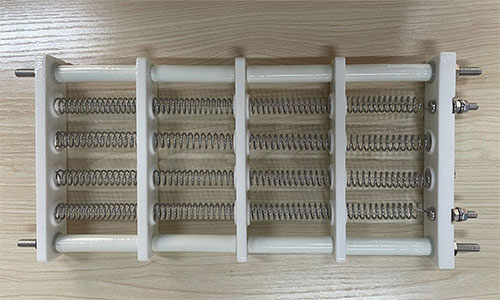

③Heating system | To provide the workroom with the required heat by high-power resistance wires with high heating efficiency and stability with 1-3.4℃/min. |  |

④Refrigerating system | The low temperature environment required for the workroom includes compressors, condensers, evaporators, throttling devices, refrigerants. |  |

⑤Humidity system | Provide the humidity required for the workroom. The humidifier produces water vapor. |  |

⑥Control system | PID programmable color touch screen controller,centralized control and management of each system to achieve accurate control of temperature, humidity and cycle times, as well as automatic operation and data recording of the test process. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español