Materials exists in a wide variety of environmental conditions throughout their service life. These materials come from automobile, aerospace, materials, electronics, military, paintings, battery, cable, PV panels, pharmaceuticals, navigation, commodity industry.

We take a look at temperature changes, one of the key factors that can significantly affect material properties and durability. However, the process of measuring the effect of temperature changes on materials based on natural time changes alone can be lengthy and costly, and the results may not be representative. In order to explore the relationship between material and temperature change, environmental temperature chamber has become a very important tool in material detection.

Before exploring the relationship between the material and temperature changes, first understand the working principle of the environmental temperature chamber.

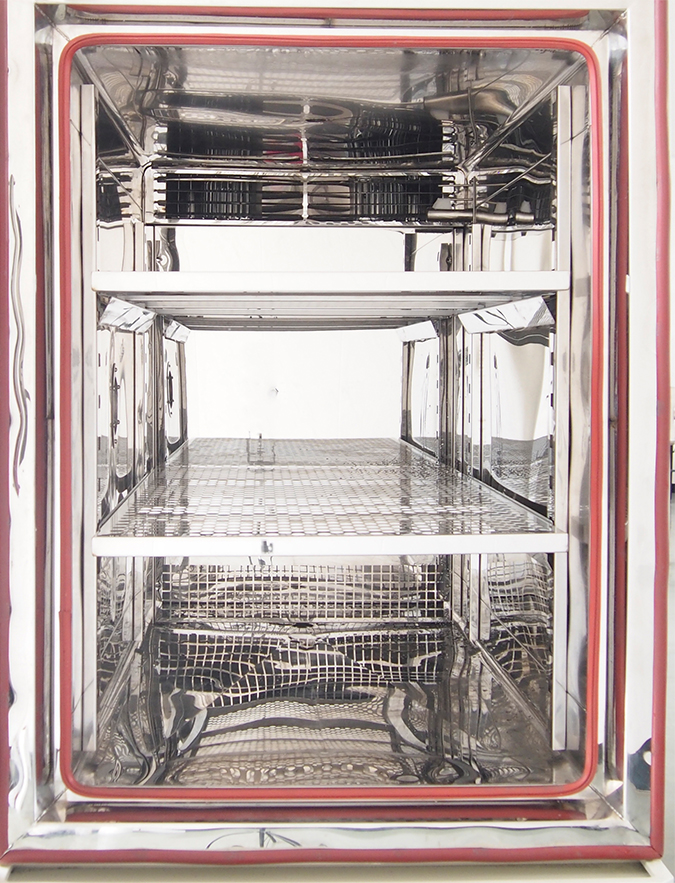

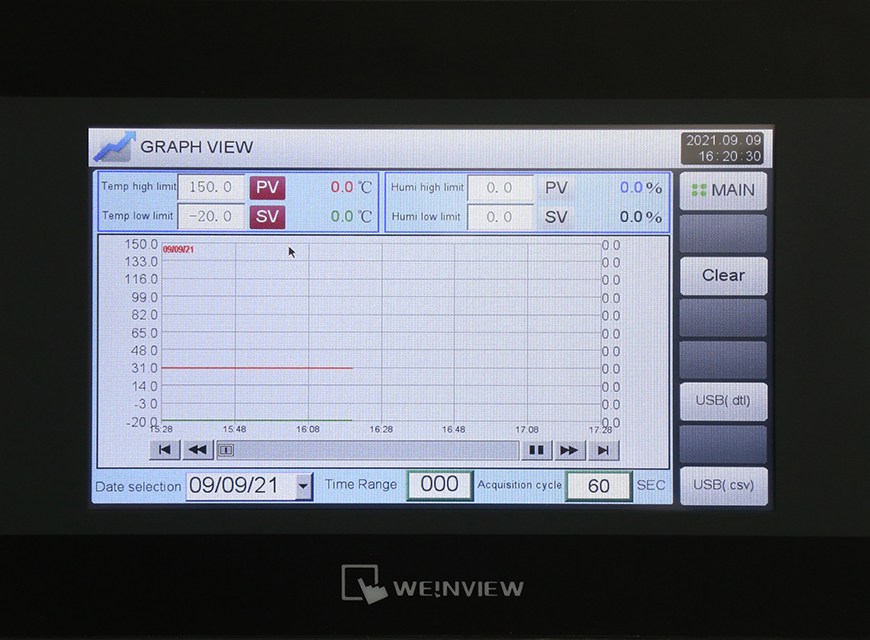

The environmental temperature test chamber has a precise control system, for heating system ,it is equipped with nichrome heater, and heating rate is 3℃/min or faster, the highest temperature can be +150℃. Besides we control temperature fluctuation and deviation respectively within ±0.5℃ and 2.0℃. For the cooling elements, which includes evaporation, compression, condensation, throttling.

After the liquid refrigerant absorbs the heat of the cooled object in the evaporator, it is vaporized into low-temperature and low-pressure steam, sucked by the compressor, compressed into high-pressure high-temperature steam, discharged into the condenser, and radiated to the cooling medium in the condenser, condensed into a high-pressure liquid, throttling through a throttle valve into a low-pressure low-temperature refrigerant, and again entering the evaporator to absorb heat and vaporize, to achieve the purpose of cycle refrigeration and to create and maintain specific temperature conditions within an enclosed space.

The environmental temperature chamber uses temperature sensor, PT-100 Class A sensor, accurancy at 0.001 degrees.to monitor the internal temperature and adjust the heating or cooling output accordingly. Meanwhile, consider how to ensure a uniform temperature distribution in a large workspace of an environmental thermal chamber? LIB industry environmental temperature chamber use air circulation system to ensure even temperature distribution throughout the test area.

A common test in a temperature controlled test chamber is the thermal cycle test. In this process, the material undergoes repeated cycles of high temperature and low temperature cycles within a period of time. For example, set the program of +85 ℃ lasting for 30 mins, later set 25℃ lasting for 20 mins and then set -40℃ lasting for 30 mins. The 3 steps constitute a cycle, and you can set the whole process time like 1000 hours. Operator can observe material changes through view window. This thermal cycle test simulates the daily or seasonal temperature variations that the material is likely to encounter in practical applications.

In the aerospace industry, after the plane takes off, as the altitude gradually increases, the air around it becomes thinner, the pressure drops, and the temperature drops. At an altitude of 6,000 meters, the temperature outside the plane drops to -24 ℃. Likewise, the durability of materials like composites, metals and coatings used in aircraft components is critical to flight safety.

The construction industry uses these environmental temperature chambers to test the performance of building materials such as insulation, roofing materials and sealants. This ensures that the material can withstand temperature changes in different geographical locations and climatic conditions because the morning and evening temperature difference in different regions and different climates, the temperature change rate is very different.

Electronic manufacturers use temperature controlled test chamber to assess the reliability and stability of electronic components and circuits under varying temperature situation. These electronic products or parts in the complex temperature situation may appear fire, smoke, explosion and so on,

In addition to the use of environmental temperature chambers to detect materials and improve their performance in all aspects, the use of temperature test chambers also has the following important significance:

By conducting various temperature tests in the laboratory environment, high maintenance and recall costs caused by product failure in the actual environment are avoided. This cost includes not only material costs, but also hidden costs such as corporate reputation.

Quickly and effectively evaluate the temperature performance of the product, reduce the time and cost of actual environmental testing, thereby speeding up the speed of product to market. In real life temperature testing can take months or years, the test chamber can exponentially shorten the test time to achieve a highly similar test environment and results.

For some safety-related products, such as electronic equipment, automotive parts, etc., to ensure their safety at extreme temperatures and reduce potential risks. This helps enterprises to improve the quality control system and demonstrate the strict control and professional attitude of the enterprise on safety and product quality.

The above is the discussion of the relationship between the environmental temperature chamber and the materials, if you want to know more information, click https://www.libtest.com/products/temperature-chamber/ to view the temperature test chamber details.

If you need professional help and solutions, please contact us inquiry@libtestchamber.com, professional team is online.