Features and Benefits of IPX6K Waterproof Chamber

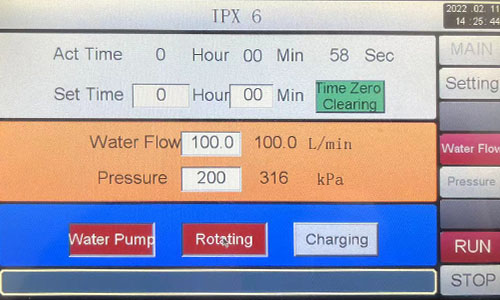

1. Provide stable 1000 kPa water pressure and 75 L/min water flow, simulate the strong water impact complying withIPX6K test standard design and manufacturing.

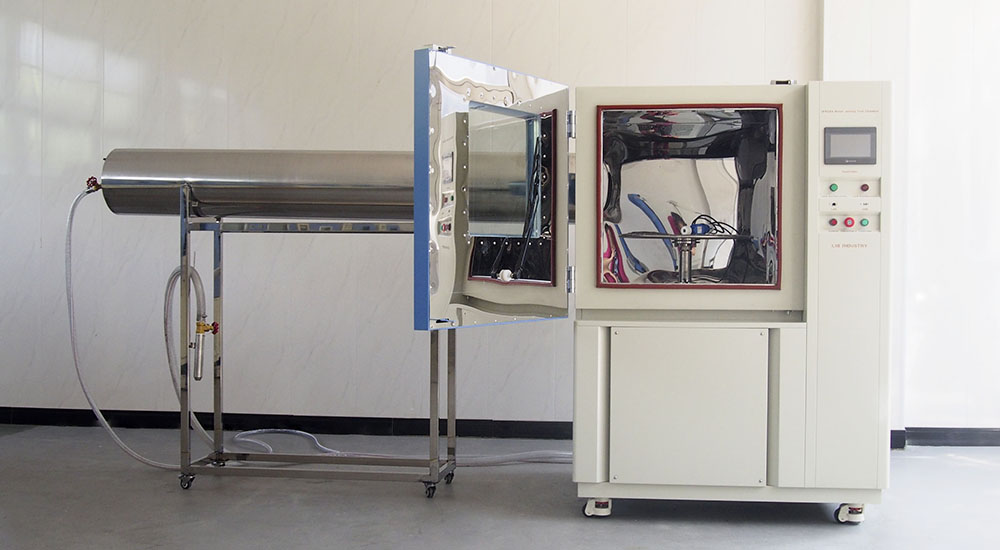

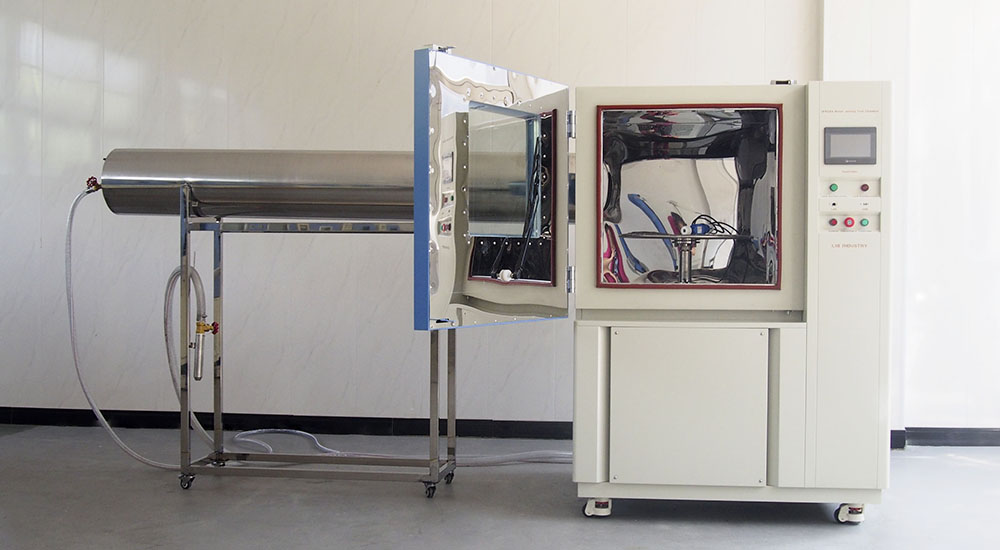

2. IPX6K waterproof chamber is made of 4mm A3 steel plate with protective coating, and the internal workroom adopts corrosion-resistant SUS304 to ensure the structural strength and prevent the water corrosion.

3. Equipped with automatic water supply and filtration system,filtering the impurities in 0.03mm particles, and can automatically supplement and adjust the water. A series of water pipes form a water circulation system.

4. Large area observation window with manual wiper, and lighting is installed inside , which is convenient for operators to understand the waterproof performance and test progress.

Specifications of IPX6K Waterproof Chamber

Model | R6K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance from Water Spraying to Specimens | between 2.5 m and 3 m. |

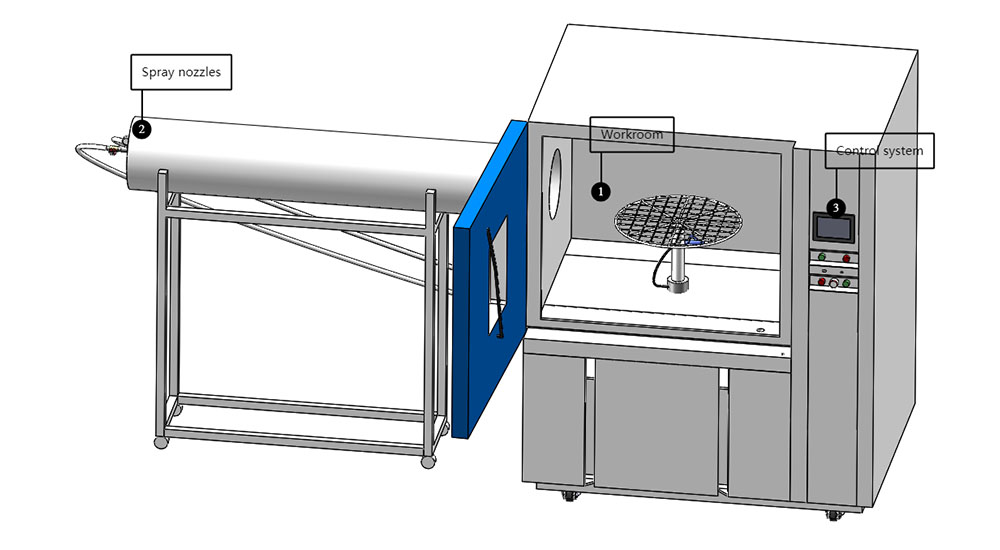

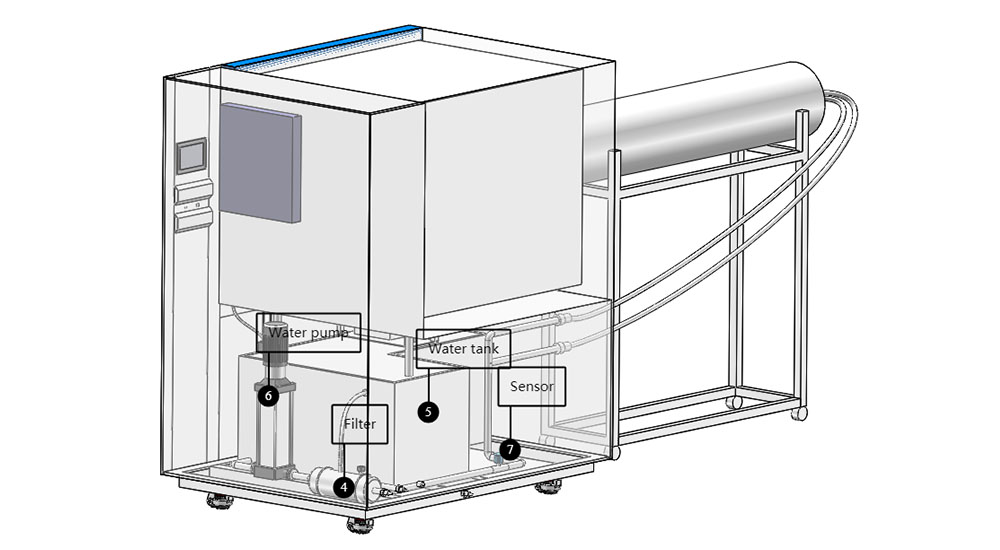

Configuration of IPX6K Waterproof Chamber

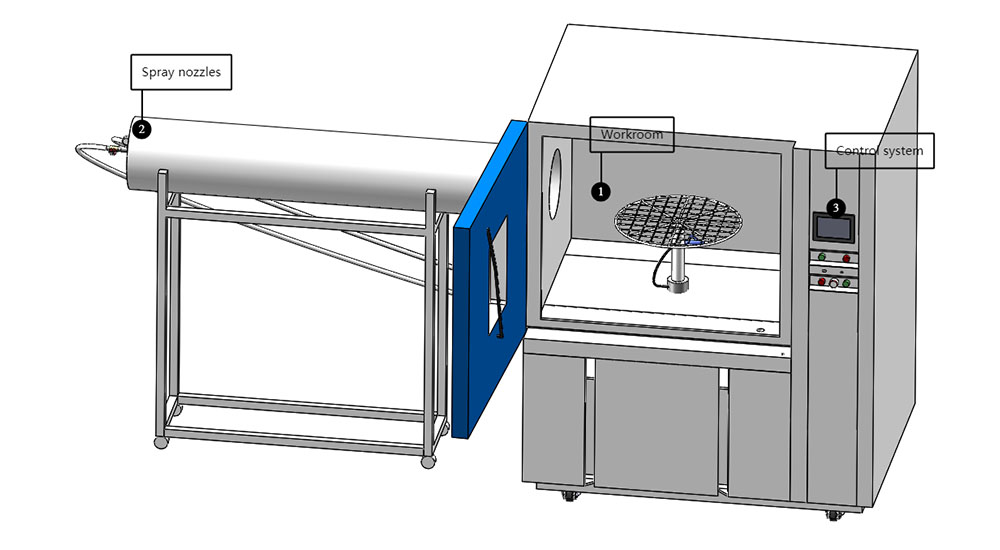

① Workroom | High pressure water is supplied from the left side of the workroom, the distance between the nozzle and the shell is 2.5-3m. The height of the turntable with waterproof power supply is adjustable, it can be turned, and it is equipped with a fixed device to prevent the measuring part from being washed away.

|

|

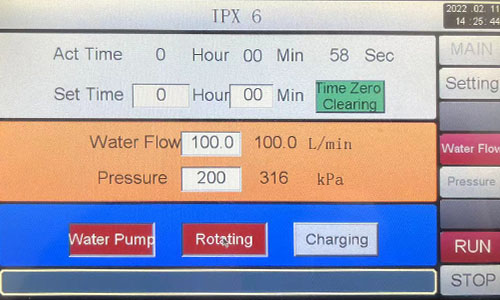

② Control system | Set and control test parameters, such as spray time, spray pressure, water flow, test cycle, etc., and monitor the data during the test.

|  |

③ Spray nozzles | The inner diameter is 6.3mm, and the material is wear-resistant and corrosion-resistant to ensure that it will not be deformed or damaged during long-term high-pressure water spraying. |  |

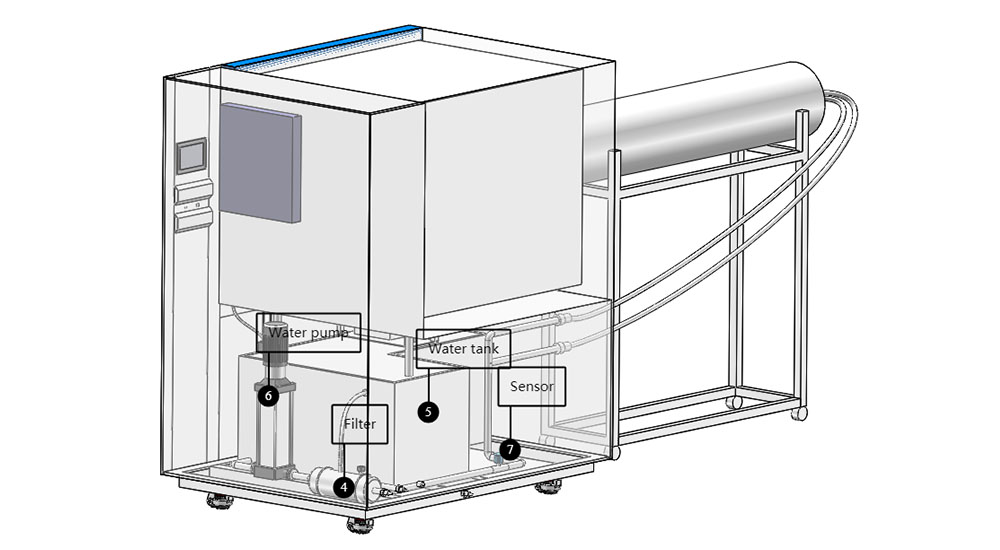

④ Filter | Automatic inlet filter system can filter out impurities in 0.03mm particles. |  |

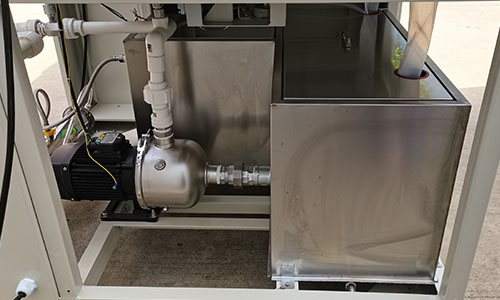

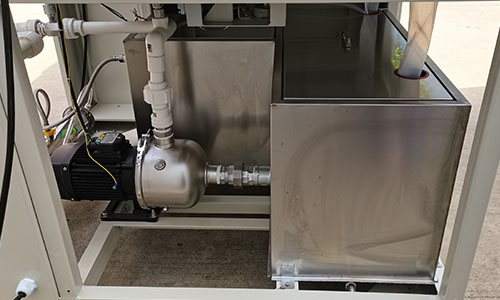

⑤ Water tank | Store the test water to provide water for the nozzle. Water level monitoring device is installed in the tank. |  |

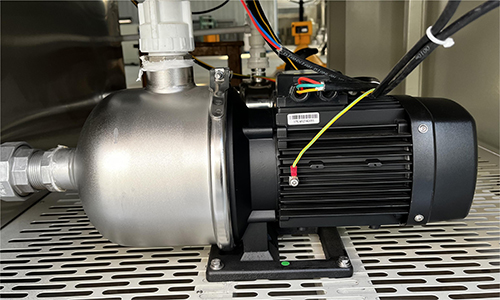

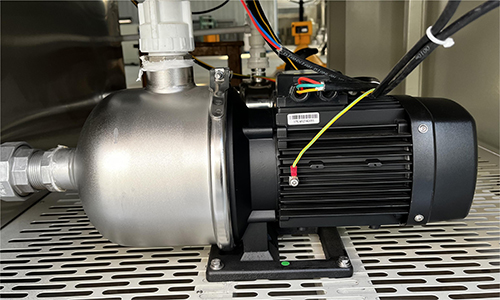

⑥ Water pump | The water in the tank is transported to the nozzle to provide pressure for the water injection. |  |

⑦ Sensor | Installed in the sprinkler system to monitor the spray pressure. |  |

![]()

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español