Features and Benefits of GMW 16001 Water Spray Chamber

1. Multiple test functions:

a. Low pressure spray: The equipment is equipped with a low pressure hose with an inner diameter of 16mm, and the water flow can reach 30L/min. It can carry out low pressure spray test, and the sealing performance of the product can be tested under low water pressure. The minimum test time is 3 minutes.

b. Water immersion test: with a specific size of the water tank, such as 300×200×200mm water tank, water level height up to 100mm, water immersion test can be carried out to test the waterproof performance of the product after a period of time in water, the minimum test time is 1 hour.

c. High pressure spray test: A high pressure nozzle with an inner diameter of 6.35mm, the nozzle type is MEG SSTC 2507, the high pressure can reach 7600kPa, and the water flow is 13L/min, which can simulate the harsh water spray environment and carry out high pressure spray test on the product.

2. High pressure nozzle can produce high pressure water mist, the pressure and water flow can be precisely controlled to ensure the accuracy and repeatability of the test.

Specifications of GMW 16001 Water Spray Chamber

Model | R-300 |

Workroom dimension (mm) D*W*H | 1200*500*500 D*W*H |

External dimension (mm) D*W*H | 1450*1000*1500 D*W*H |

Interior Volume (L) | 300 Liters |

Diameter of Turntable (mm) | 350 |

Turntable loads | 50kgs |

Parameter | Turntable Rotation Speed | 1~7 r/min (Adjustable) |

Low pressure Spray | Internal Diameter of Low pressure hose | 16mm |

Water Flow Rate | 30L/min |

Minimum test time | 3 minutes |

Water Submersion Test | Water box size(mm) | 300*200*200 |

The height of water | 100mm |

Minimum test time | 1 hour |

High pressure Spray Test | Internal Diameter of High pressure Nozzle | 6.35mm |

High pressure Nozzle Type | MEG SSTC2507 |

High pressure | 7600Kpa |

Water Flow Rate | 13L/min |

Structure | Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

Water Supply System | Water tank, booster pump, Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Material | Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

Power Supply | 220V 60Hz 1P |

Maximum Noise | 65 dBA |

Environmental Conditional | 5℃~+35 ℃ ≤85% RH |

Standard | GMW16001 |

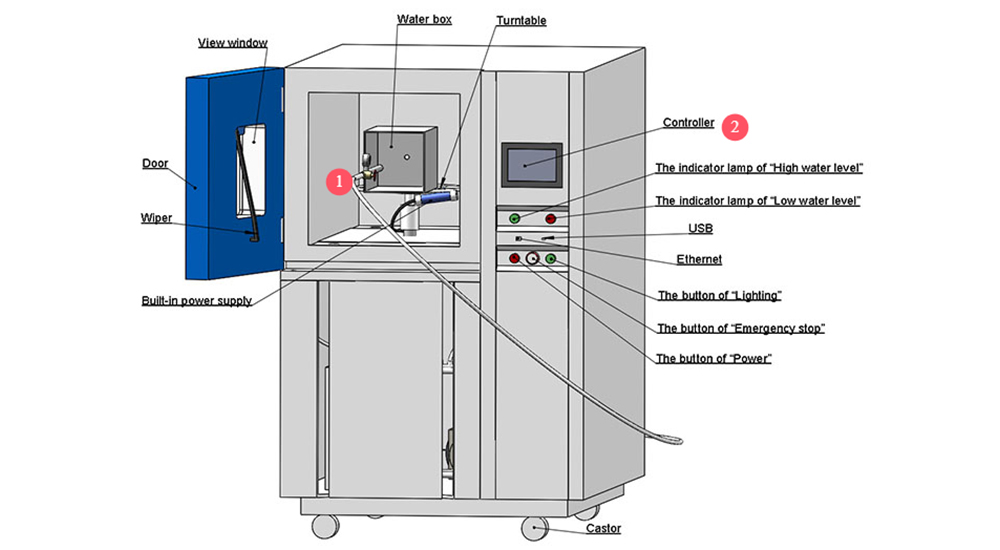

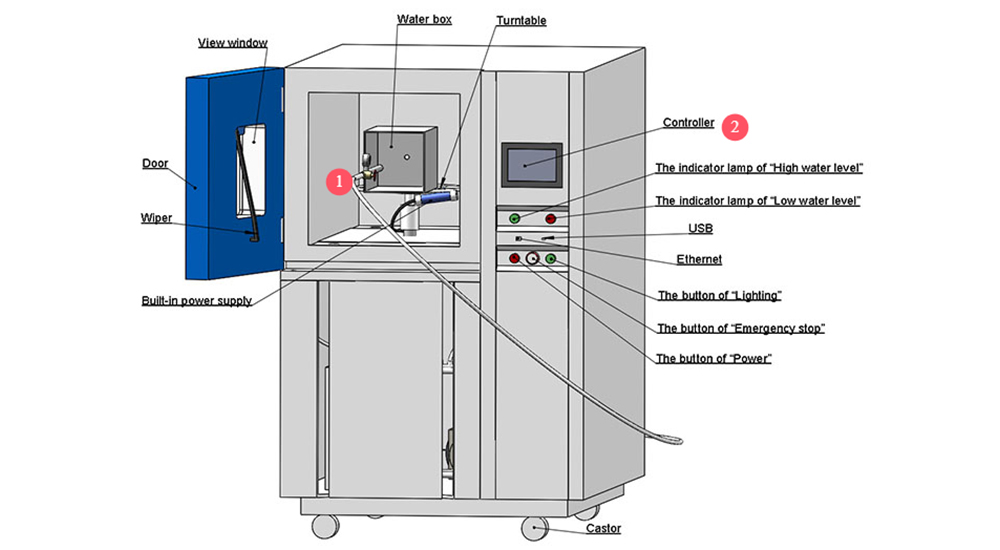

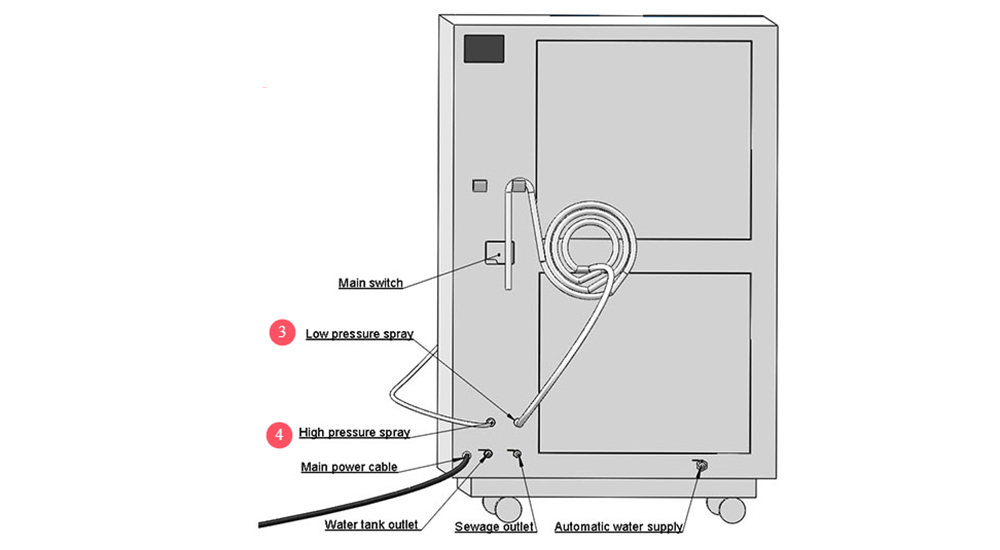

Configuration of GMW 16001 Water Spray Chamber

①Workroom

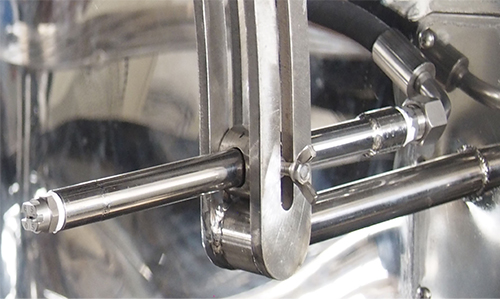

made of 304 stainless-steel,mirror surface, rust-proof, high temperature and corrosion resistance;

Test specimen is placed and fixed on turntable and turntable rotation speed is 1~5 r/min(adjustable).Turntable loads 50KG

Equipped with a single-phase 16A internal power interface.

②Controller

Programmable touch screen controller, easy to operate, can set such as test time, water flow, pressure, rotary speed, and real-time monitoring of the test process.

Remote control and data transmission are supported.

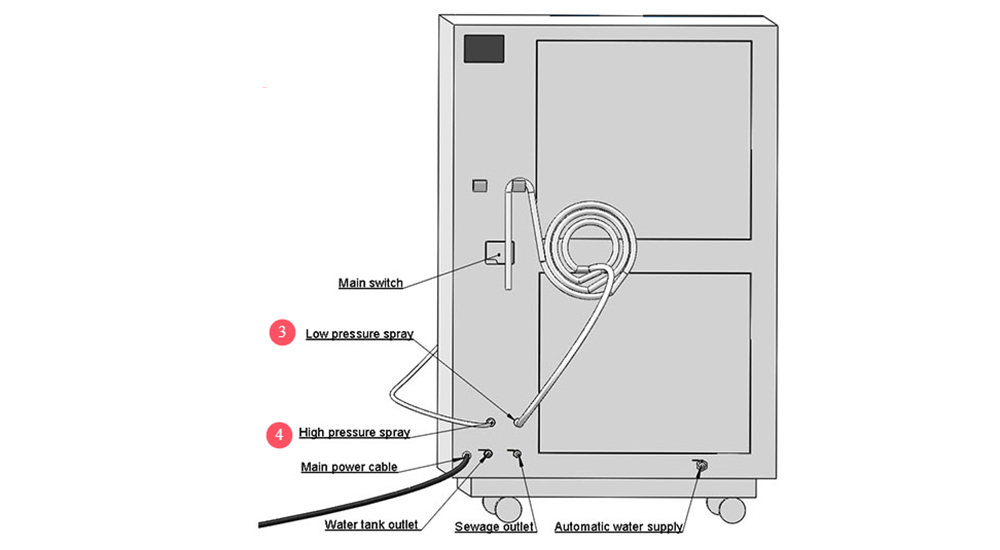

③Low pressure spray

Meet the needs of low pressure spray test, simulate the product in the case of light rain or slight water splash sealing.

④High pressure spray

simulate the harsher water injection environment, high pressure spray test products, testing products under high pressure water impact sealing performance.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español