IPX9K is a very high level of waterproof performance in the international protection class standard. It is mainly used to evaluate the water resistance of products in extreme high temperature and high pressure spray environments. In IPX9K testing, the test equipment is required to be able to generate water at temperatures up to 80 ° C to 90 ° C and pressures between 8,000 kPa and 10,000 kPa, and spray the product under test at a specific Angle and flow rate. The harsh test conditions are designed to simulate the worst possible flooding conditions in real-world use scenarios, such as a car undergoing high-temperature steam cleaning or a strong current impact while driving at high speed in a rainstorm.

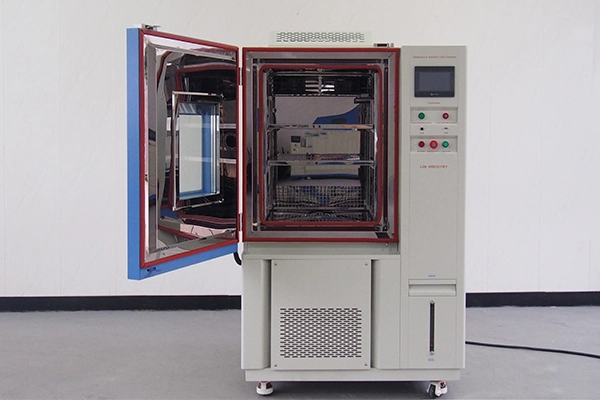

In the context of the increasingly demanding waterproof performance of components in the automotive industry, the IPX9K test equipment of the LIB brand stands out due to its advantages.

LIB's IPX9K test equipment is excellent at simulating extreme environments. A specially designed array of nozzles in its spray system precisely produces a high temperature and high pressure water flow that meets the requirements of the standard. Whether the pressure setting is 8000 kPa or 10000 kPa, the output can be stabilized, and the temperature can be accurately controlled at any value between 80 ° C and 90 ° C with minimal deviation.

The IPX9K device can simulate the harsh flooding environment faced by the connector when the engine is suddenly hit by heavy rain or steam cleaning after a long period of high temperature operation. Through accurate simulation of water flow impact, the waterproof tightness of the connector is fully tested to ensure that it will not cause circuit failure due to water intrusion in actual use, and ensure the safe and stable operation of the automotive electrical system.

Highly intelligent automatic control system, simple and intuitive human-machine interface, operators can easily set a variety of test parameters, such as spray time can be accurate to seconds, water pressure, water temperature and the number of cycles can be flexibly adjusted according to the test needs of different parts. Moreover, during the testing process, the intelligent monitoring and diagnosis function of the system always plays a role. It is able to monitor every operation of the equipment in real time, and in case of any abnormal situation, such as water pressure fluctuations beyond the allowable range, temperature control failure, and so on, it will immediately issue an alarm. Taking the test of electronic components in the automobile brake system as an example, the operator only needs to input the corresponding test standard parameters in the control system, and the equipment will automatically complete the entire test process, and generate a detailed test report, which provides a reliable basis for product quality assessment, and also provides valuable data support for R & D personnel to further optimize product design.

The LIB IPX9K test equipment is equipped with high-precision pressure sensors and temperature sensors, which use advanced sensing technology to accurately measure the pressure and temperature changes of the water flow, and its measurement error range is strictly controlled within a very small interval. At the same time, the unique water flow distribution system inside the equipment is a highlight. The system ensures maximum uniformity of water flow throughout the test area through carefully designed pipe layout and flow regulation. Whether it is a large car body structure or a tiny electronic sensor, it can be subjected to uniform water flow when being tested, so that the test results can accurately reflect the true waterproof performance of various parts of the parts.

The LIB IPX9K test equipment is made of high-quality materials as a whole, and the shell is made of special alloy materials with strong corrosion resistance. The key internal components, such as pumps, valves, sensors, etc., are made of high-quality products that have been rigorously screened and durability tested, have good wear resistance, and can withstand long-term, high-intensity test tasks. In addition, the design of the equipment fully takes into account the convenience of later maintenance, and adopts a modular design concept. Each function module is independent and closely coordinated with each other, when a module fails, it can be easily disassembled and replaced separately, without large-scale disassembly and maintenance of the entire equipment.

This modular design not only greatly shortens the maintenance time of the equipment, reduces the maintenance cost, but also improves the overall service life and cost performance of the equipment. For the large-scale and frequent waterproof testing needs of parts in the automotive industry, this durable, reliable and easy to maintain feature is undoubtedly a very important advantage, to ensure that the test equipment has always maintained stable performance during long-term use, providing continuous and reliable protection for the quality inspection of auto parts.

If you are in the automotive manufacturing or related parts production industry and are struggling to test the waterproof performance of your products, the IPX9K test equipment of the LIB brand will be your ideal solution. Don't hesitate to contact us today inquiry@libtestchamber.com and let our professional team explain how this device can help you improve your product quality and stand out from the fierce competition in the market.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español