IP dust chamber is a device used to test the dustproof performance of products, which can simulate various dust environments, such as deserts, mines, construction sites, etc. By putting the product into the test chamber and blowing the dust for a certain time, the sealing performance of the shell of the product, the filtering effect of the filter, and the dust resistance of the electronic components can be tested.

The main function of the IP dust chamber is to evaluate the reliability and durability of the product in a dust environment. In practical applications, many products need to work in a dust environment, such as automobiles, aerospace equipment, communication equipment, electronic products, etc. If the dustproof performance of these products is not good, it will lead to product failure, damage and even endanger personal safety. Therefore, through the test of the IP dust chamber, the dust prevention problem of the product can be found in advance, improved and optimized, and the quality and reliability of the product can be improved.

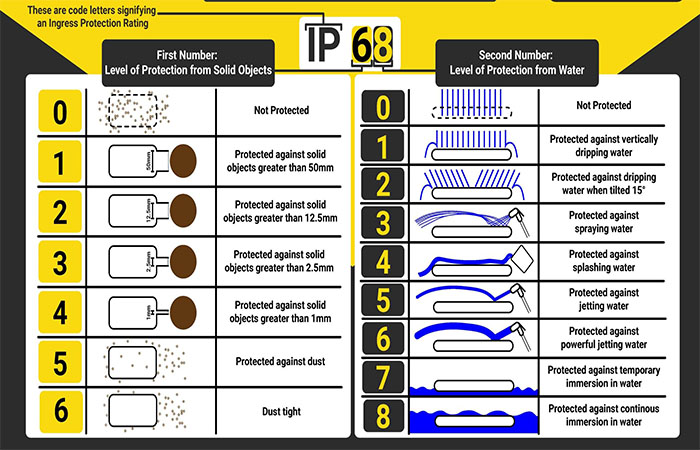

"IP" stands for Ingress Protection, usually a two-digit number to indicate the product's ability to protect against solid foreign objects and liquids. The dust test chamber is mainly used to test the protection level of the product against solid foreign objects (such as sand and dust). The dust protection level test is the first characteristic number, and there are a total of grades (IP00-IP6X), but generally only IP5X and IP6X are two dust protection levels.

The reason is that IP00 in the standard: no dust protection at all; IP1X: can protect foreign bodies with a diameter greater than 50mm from falling into the equipment; IP2X: protects foreign objects larger than 12.5mm in diameter from falling into the equipment; IP3X: can protect from foreign bodies with a diameter greater than 2.5mm falling into the equipment; IP4X: Protects foreign objects larger than 1.00mm in diameter from falling into the device. These protection levels are very low, so the environmental test equipment industry does not manufacture corresponding test chambers for these four characteristics.

The requirements of IP5X and IP6X are respectively, IP5X: cannot completely prevent the dust from entering, but the amount of dust entering shall not affect the normal operation of the equipment and shall not affect the safety; IP6X: completely dustproof, can be considered as high as the dustproof level.

The IP dust chamber generally adopts the method of suspending talc powder to simulate the dust environment. Talc applied metal square hole sieve filtration, wire diameter 50μm, sieve size 75μm, talc dosage per cubic meter test chamber volume 2kg, the number of use can not exceed 20 times.

In fact, the test dust of the sand and dust test chamber not only has talc powder, but also mentions Portland cement, olivine or smoke ash in other standards, and its dust blowing method also has continuous and periodic options.

IP dust chamber is to blow dust into the test chamber through the fan to form a certain concentration of dust environment. Parameters such as temperature, humidity and wind speed in the test chamber can be adjusted according to needs to simulate different sand and dust environmental conditions.

During the test process, the product is placed on the sample rack in the test chamber, and the dustproof performance of the product is evaluated by observing the appearance changes and performance indicators of the product. The test time can be set according to the actual use of the product, generally ranging from a few hours to a few days.

The technical parameters of IP dust chamber mainly include:

1. Temperature range: usually room temperature ~50℃, can be adjusted according to needs.

2. Humidity range: usually 30%RH, can be adjusted according to needs.

3. Dust concentration: usually 2/m³, can be adjusted according to needs.

4. Sample rack size: It can be customized according to needs to meet the needs of different sizes of product testing.

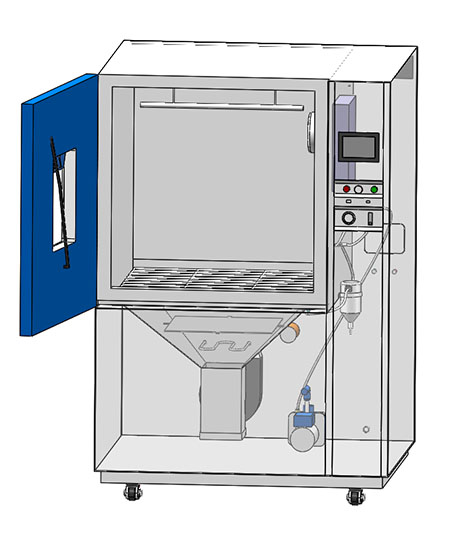

IP dust chamber is mainly composed of chamber, fan, dust generator, control system and so on.

1. chamber

The chamber is the main part of the IP dust chamber, which is made of SUS 304 and has good corrosion resistance and sealing. The chamber is provided with sample rack, observation window, lighting equipment, etc., to facilitate user observation and operation.

2. Fan

The fan is one of the core components of the IP dust chamber, which is responsible for blowing sand into the test chamber to form a dust environment. The power and wind speed of the fan can be adjusted as needed to meet different test requirements.

3. Sand generator

The dust generator is an important part of the IP dust chamber, which is responsible for producing dust. The dust generator usually uses compressed air to blow the dust into the test chamber to form a certain concentration of dust environment. The type and particle size of dust can be selected according to the need to simulate different dust environmental conditions.

4. Control system

The control system is the brain of the IP dust chamber, which is responsible for controlling the temperature, wind speed and other parameters of the test chamber, as well as monitoring and recording the test data.

In short, the IP dust chamber is an important test equipment, which can simulate harsh dust environments and test the dustproof performance of the product. When using the IP dust chamber, it is necessary to pay attention to safe operation, sample preparation, test parameter setting and equipment maintenance to ensure the accuracy and reliability of the test results.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español