The vibration chamber is the synthesis of three quantities of temperature and humidity vibration, which refers to the test of three environmental stresses of comprehensive temperature + humidity + vibration. It can be used to assess the adaptability of the product in the environment of temperature, humidity and vibration.

Compared with the effect of a single factor, it can more truly reflect the adaptability of electrical and electronic products to temperature, humidity and vibration complex environment changes in transportation and actual use, and expose product defects, which is an essential and important test means for the whole process of new product development, prototype test and product qualification test.

Temperature and humidity test chamber, lifting platform, blind plate for temperature and humidity test, blind plate with PU cloth, support frame, horizontal and vertical shaking table, power amplifier, computer, cooler, etc. Here we do not describe the content of the temperature and humidity chamber, mainly explain the vibration table and its vibration principle.

The vibration system is mainly made of

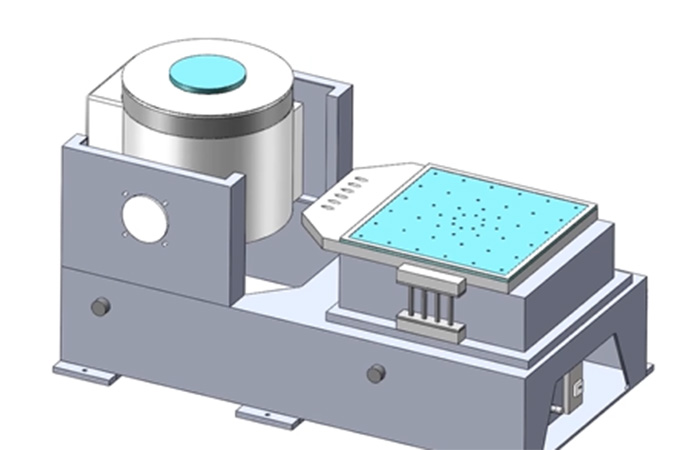

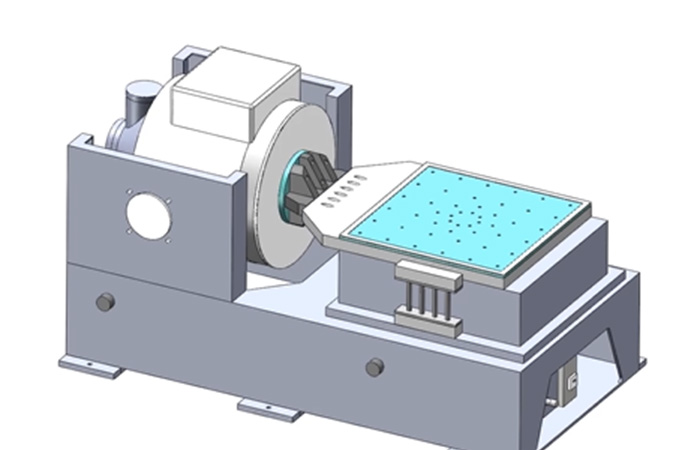

The core component that generates vibration, divided into vertical shaking table and horizontal shaking table, usually composed of a table, a vibration exciter, a guide mechanism, a support spring, etc.

The table is the platform on which the sample to be tested is placed, the exciter is the power source that generates the vibration, the guiding mechanism ensures the accuracy of the vibration direction, and the support spring acts as a buffer and support.

Used to control the vibration frequency, amplitude and direction of the vibration table.

The control system can control the vibration characteristics of the shaker by adjusting the output parameters of the shaker, such as frequency, amplitude and phase.

Used to detect vibration parameters of the shaker, such as acceleration, speed, displacement, etc.

The sensor transmits the detected vibration signal to the control system, and the control system automatically adjusts the output power of the vibration table according to the difference between the set vibration parameters and the actual vibration parameters to achieve accurate vibration control.

Both horizontal vibration and vertical vibration of temperature and humidity vibration test chamber need exciter arrangement. For horizontal vibration, the shaker is usually mounted on the side or bottom of the shaker and causes the table to vibrate horizontally by generating a force in the horizontal direction. For vertical vibration, the shaker is usually mounted on the bottom or top of the shaker and causes the table to vibrate vertically by generating a force in the vertical direction.

For guiding mechanism design. In order to ensure the direction accuracy of horizontal vibration, the guiding mechanism is usually in the form of linear guide rails, sliders or rollers. In order to achieve vertical vibration, the stiffness and preload of the support spring need to be adjusted.

In short, the temperature and humidity vibration test chamber can realize the independent control and accurate simulation of horizontal vibration and vertical vibration through reasonable design of the shaking table structure, selection of appropriate exciter and guiding mechanism, and precise adjustment of vibration parameters through the control system, which provides a strong support for the reliability test of products.

In the two blind plates, one is specially designed for vibration testing, this blind plate with PU cloth. The PU cloth is equipped with punching holes, and the punching is consistent with the punching of the vibrating table, and its main function is to fix the test part. Since the blind plate has a certain weight, it is also equipped with a support frame. On the one hand, the support frame can support the blind plate, and on the other hand, it also provides convenience for the replacement of the blind plate.

The control principle of the vibration table is as follows: The vibration controller sends the low-power driving electrical signal evenly to the power amplifier. The power amplifier amplifies the received low-power drive electrical signal and provides it to the drive coil of the shaker, thus pushing the drive coil of the shaker to move. The acceleration sensor is responsible for collecting vibration signals and transmitting the collected vibration signals to the vibration controller. The vibration controller corrects the received electrical signal in real time and then sends it back to the power amplifier to achieve closed-loop feedback control.

For the shaking table body, when the vertical vibration test is carried out, the test part is put into the test chamber, and then the temperature and humidity chamber is directly moved, and the test part is placed on the vertical vibration table, so that the test part can be reciprocated in the vertical direction. In the horizontal vibration test, the vertical vibration table needs to be removed first,

then the connecting head is put on, and the shaking table body is rotated so that the connecting head is aligned with the horizontal vibration table. Finally, the test chamber is moved to the surface of the horizontal shaking table so that the test piece is reciprocated in the horizontal direction.

In short, the temperature and humidity vibration test chamber can realize the independent control and accurate simulation of horizontal vibration and vertical vibration through reasonable design of the shaking table structure, selection of appropriate exciter and guiding mechanism, and precise adjustment of vibration parameters through the control system, which provides a strong support for the reliability test of products.