Today, we will introduce the MIL-STD-810H sand and dust test chamber and MIL-STD-810H rain test chamber of LIB. When we talk about MIL-STD-810 test chamber, we have to mention MIL-STD-810 first. MIL-STD-810 is a U.S. military standard that emphasizes adjusting the environmental design and test limitations of a device based on the conditions experienced by the device throughout its service life, and establishing indoor test methods that simulate the effects of the environment on the device.

In short, MIL-STD-810 is a set of environmental test methods and standards designed for the U.S. military that are now being adopted and recognized by various industries, especially those working outdoors. The H in MIL-STD-810H is actually the version number of MIL-STD-810, which is constantly redefined and constantly adjusted test methods and standards according to the needs of specific users at different times, thus evolving.

The MIL STD 810 standard was originally developed by the U.S. military to ensure that military equipment can operate stably and perform its intended function in a variety of harsh and complex environments. With the passage of time, the influence of the standard has gradually gone beyond the military field, and is widely used in many civilian industries such as aerospace, electronics, automobiles, and communications.

The scope of application of this standard is extremely broad, covering a variety of products from electronic components to large machinery and equipment. Its core purpose is to comprehensively test the performance and reliability of the product in the face of various harsh environmental stresses by simulating a range of extreme environmental conditions, including drastic changes in temperature, high humidity, strong vibration, shock, salt spray erosion, dust invasion, etc.

The various environmental conditions covered by MIL-STD-810H include:

Low pressure height test; Plus high and low temperature shocks during storage and use; Rainfall impacts, including wind and freezing rain; Moisture, fungi and salt spray are tested for rust resistance to exposure to sand and dust; Explosive atmosphere; Leakage and leakage

To promote; Shock and shock transport; Gunshots vibrate; General vibration.

We're only talking about dust and rain here.

1. Working principle and simulation environment

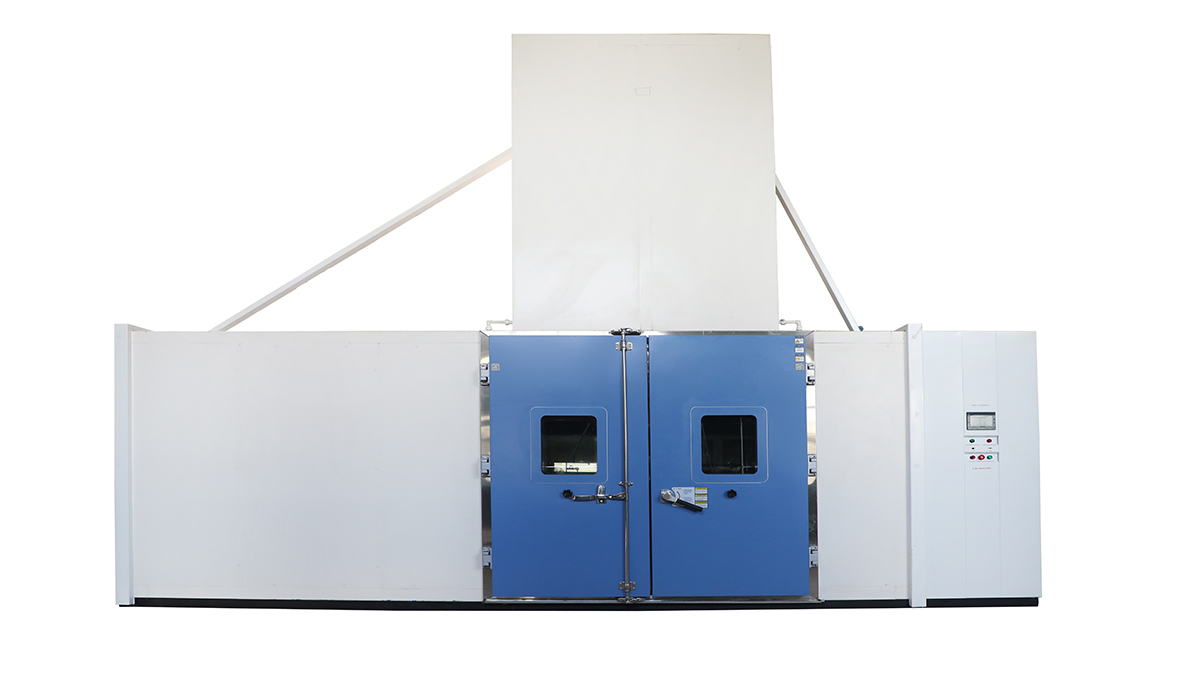

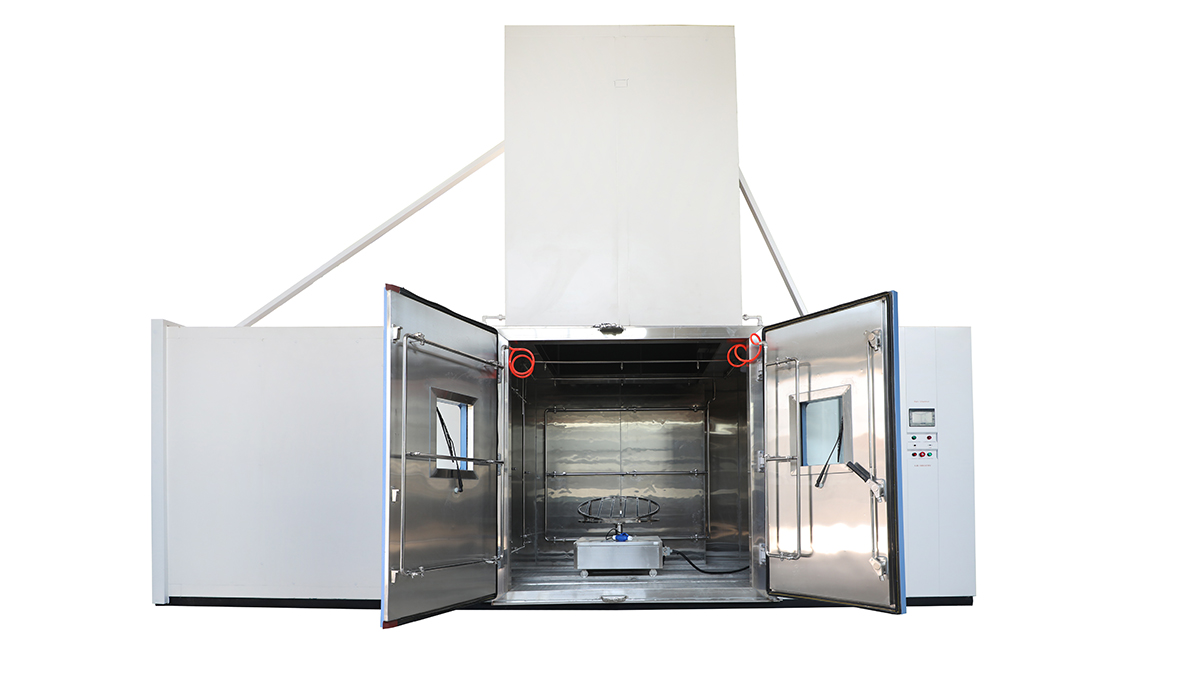

The MIL STD 810 rain test chamber is designed to simulate different intensification and forms of rainfall through a carefully designed spray system. Its working principle usually includes water supply system, pressure regulation device, sprinkler and control system. The water supply system provides a steady flow of water, and the pressure regulating device ensures that the nozzle spews rain with a specified pressure and flow rate to simulate a variety of rainfall conditions from drizzle to rainstorm (rainfall intensity).

This simulated environment can truly reproduce the rain conditions that the product may encounter outdoors, including vertical rainfall, inclined rainfall and the combination of wind and rain, etc., so as to comprehensively test the product's rainproof performance, sealing performance and working reliability in wet environments.

2. Technical characteristics and performance indicators

The rain test chamber has a series of key technical characteristics and performance indexes. The design and layout of the nozzle is designed to achieve an even distribution of rain, ensuring that all parts of the product under test are subject to the same degree of rain impact. In addition, the content of impurities and particles in rainwater is strictly controlled to ensure the accuracy and repeatability of the test.

Performance indicators include final raindrop velocity (9m/ s), rain rate (≥1.7mm/ min), rain drop diameter (0.5mm ~ 4.5mm), nozzle pressure (276Kpa). The high-precision control and adjustment function enables the test chamber to meet the requirements of the MIL STD 810 standard for a variety of complex rain scenarios, providing strong support for product reliability assessment.

3. Application fields and importance

In the aerospace field, aircraft shells, engine components and electronic equipment need to be subjected to rain tests to ensure flight safety in adverse weather conditions. In the automotive industry, vehicle bodies, window seals, lights and electronic control systems must pass rain tests to verify their waterproof performance and normal operation in wet environments. For electronic communication equipment, such as mobile phones, base stations and communication cables, the rain test helps to evaluate its signal transmission stability and electrical performance in wet climates.

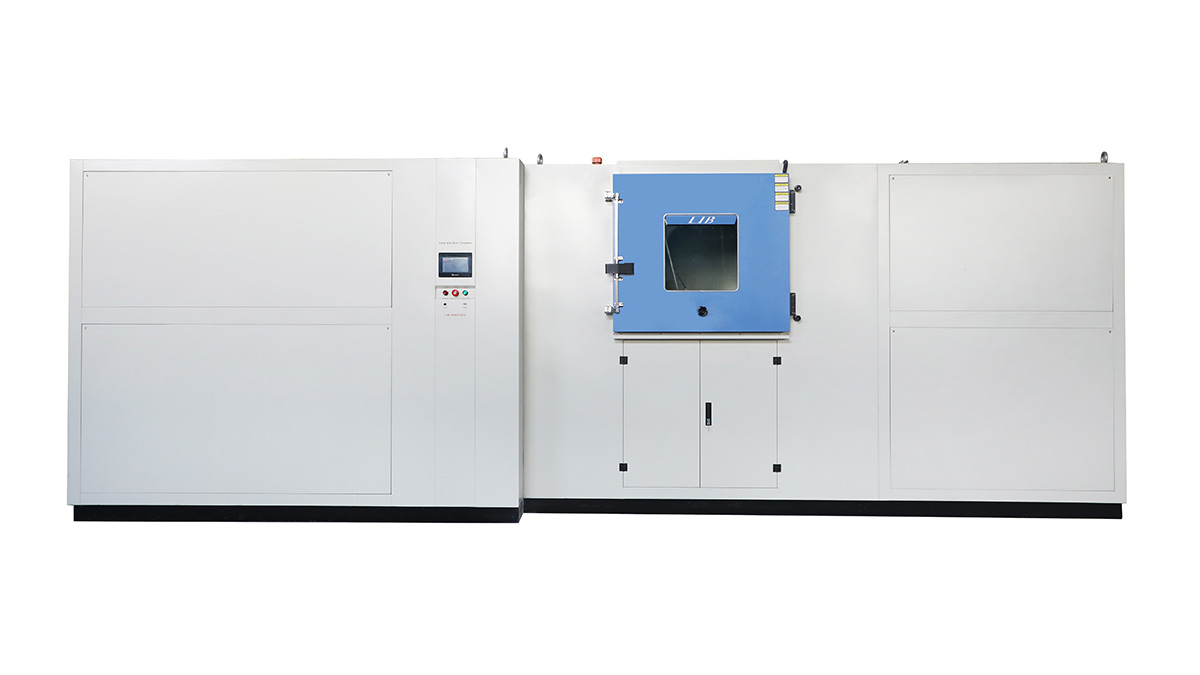

1. Working principle and simulation environment

The operating principle of the MIL STD 810 dust test chamber is based on an air circulation and dust injection system. Powerful air flow is generated by the fan, and the dust particles are blown into the test chamber to form a certain concentration and speed of the dust environment. At the same time, the adjustable wind speed, dust concentration and particle size can simulate a variety of harsh dust conditions from light dust to severe dust storms. Including blowing dust and blowing sand. Dust blowing: wind speed 1.5-8.9m /s, density 10.7±7g/ m³, particle diameter < 150μm; Sand blowing: wind speed 18.0-29.0 m/s, density 0.18+0.2g/m³; 1.1 + 0.3 g/m after; 2.2+0.5g/m³, particle diameter 149 μm-600 μm, 600 μm-850 μm.

This simulated environment can truly reflect the dust invasion that the product may face in the desert, arid areas or dusty working environment, so as to test the protection performance of the product shell, the effectiveness of the ventilation and filtration system, and the reliability of the internal components in the dust environment.

2. Technical characteristics and performance indicators

The technical characteristics of the dust test chamber are mainly reflected in the dust generation and injection mode, the air circulation system in the chamber and the monitoring and control of the dust concentration. The advanced dust injection system ensures the uniform distribution of dust particles and has adjustable injection Angle and speed.

3. Application fields and importance

In the military industry, weapons and equipment, armored vehicles and communication equipment must have good dust-proof performance to adapt to the harsh environment of the battlefield. Dust testing can ensure the normal operation of these devices under sand-filled conditions to maintain combat effectiveness and communication capabilities.

In the power industry, transformers, switchgear and power meters and other equipment are often exposed to the outdoor environment, and the sand and dust test helps to evaluate their insulation performance and protection level to ensure the stable operation of the power system. For new energy fields, such as solar panels and wind power equipment, dust tests can test the effect of their surface cleaning and protection systems, improving power generation efficiency and equipment life.

MIL STD 810 rain test chamber and dust test chamber as an important tool to assess the environmental reliability of products, in order to ensure product quality, enhance the competitiveness of enterprises and promote the development of the industry plays a key role. Through continuous technological innovation, strict operation and maintenance and integration with emerging industries, they will provide stronger support for future product research and development and quality control, creating higher quality and more reliable products for various industries.