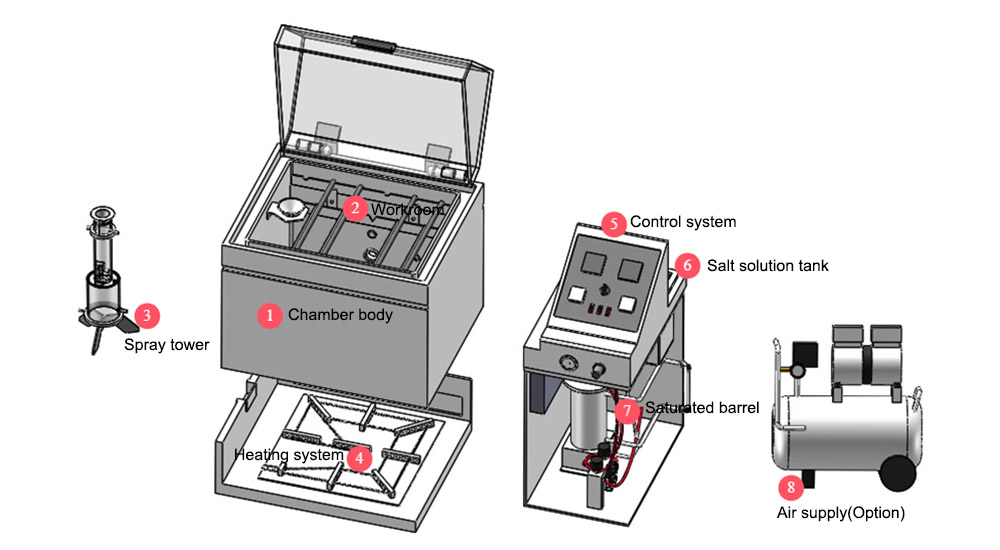

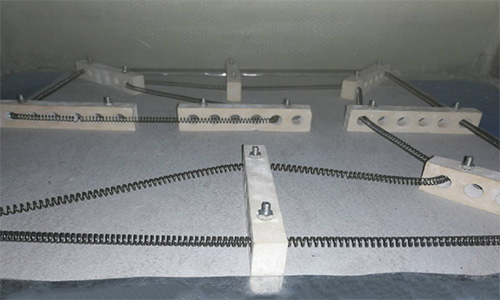

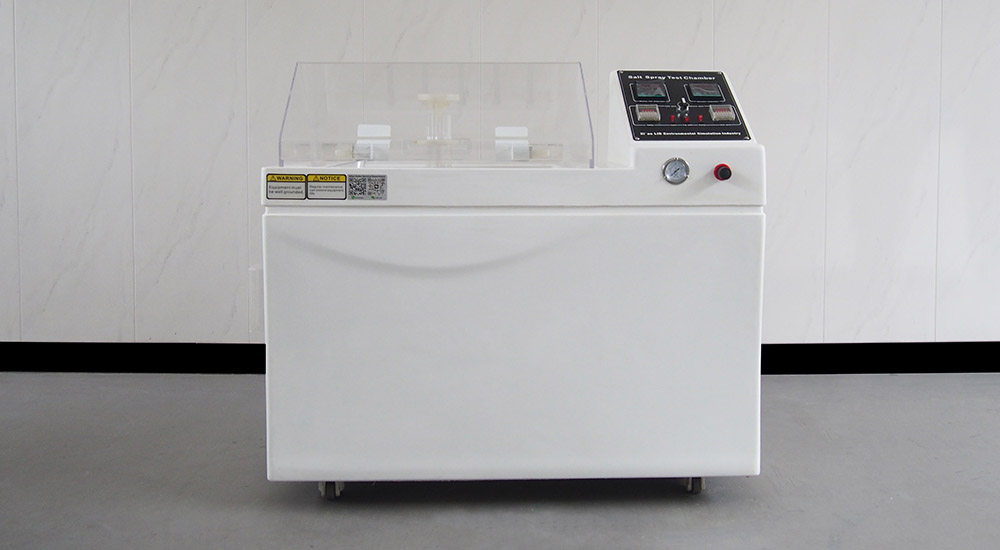

ASTM B117 salt spray environmental test chamber follows ASTM B117 standard and is used to evaluate the salt spray corrosion resistance of metals. The temperature is controlled at 35℃, the humidity is kept above 95%, and the concentration of salt spray 5% is uniform.

Depending on the size of the workroom, the shape of the test piece, the required configuration and the environment, LIB provides a variety of personalized salt spray test chambers. The perfect after-sales policy, contact us today.

Model: S-150,S-250, S-750, S-010, S-016, S-020

Standard: ASTM B117, ISO 9227, ASTM G85, D17 2028, SAE J2334, ISO4611, ISO7253, BS3900-F12, IEC 60068-2-11, DIN 50021, ASTM G85-02e1 Annex A1,BS 7479, ASTM B368

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español