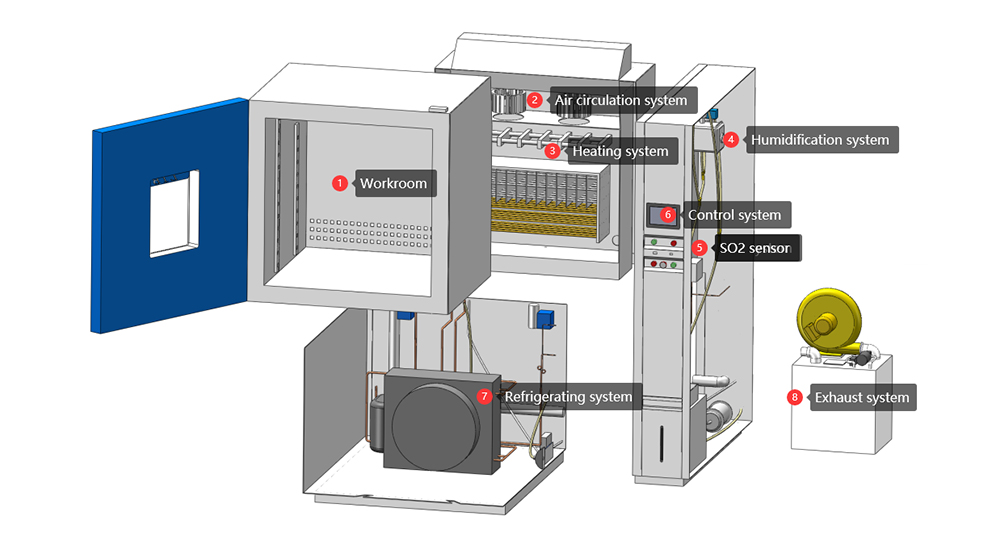

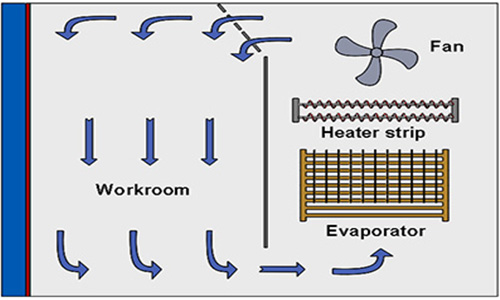

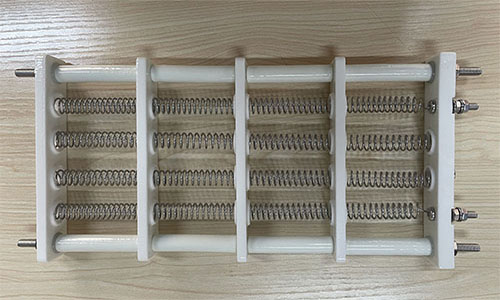

SO2 corrosion test chamber simulates the materials corrosion under SO2 gas environment, introduces SO2 gas into the workroom, and precisely controls the concentration of SO2 with 1 ~ 30 ppm, temperature ranging from 15 ℃ to 80 ℃and humidity with 30% ~ 98%RH.

Diverse size and models of so2 corrosion test chambers are available including reach in,walk in and customized types.

Model: GC-100, GC-225, GC-500, GC-800, GC-1000, SO-100, SO-225, SO-500, SO-800, SO-1000

Standard: ISO 6988, ISO 3231, DIN 50018, ASTM G87-02, IEC 60950:22, IEC 60068-2-42, IEC60068-2-6

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español