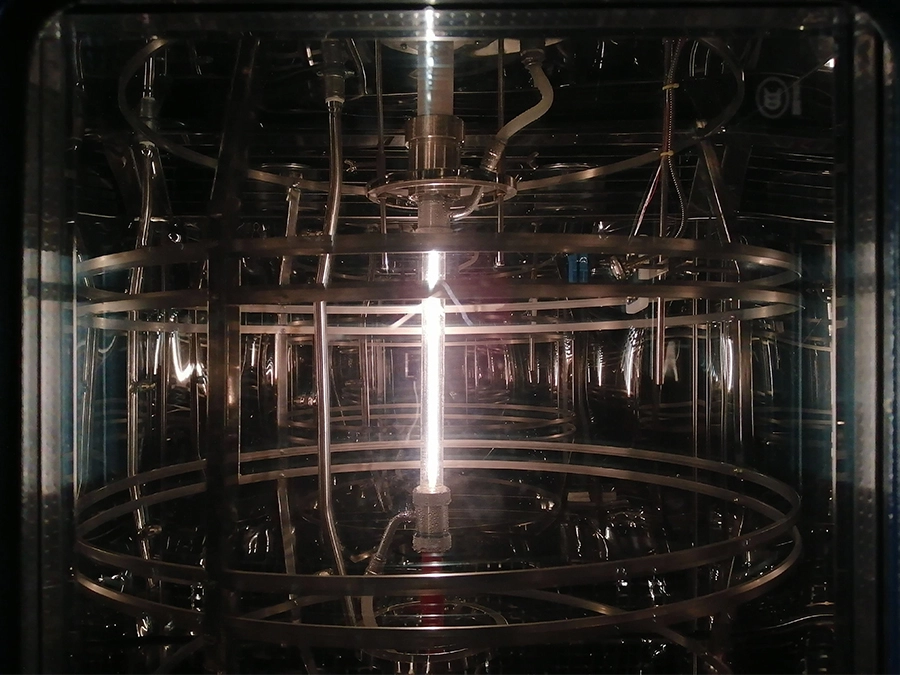

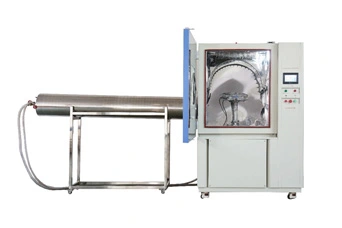

A constant temperature and humidity test chamber is a device used to simulate various environmental conditions for testing materials, products, and equipment under stable temperature and humidity settings. It is widely used in electronics, electrical appliances, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical, aerospace, and other fields. The primary function is to provide a stable and controllable environment where test samples are exposed for a period to observe and analyze their performance changes, durability, and stability under specific conditions.

1、Precise Temperature and Humidity Control: The chamber can accurately control the internal temperature and humidity, ensuring the stability of the testing environment.

2、Energy Efficiency and Environmental Protection: It utilizes advanced cooling, heating, and humidifying technologies to reduce energy consumption and comply with environmental protection standards.

3、Intelligent Control: Equipped with an intelligent control system, the chamber allows for pre-setting test conditions, automated operation, and data recording, minimizing manual intervention.

4、Safety Protections: The chamber includes multiple safety features such as over-temperature protection and overload protection, ensuring the safety of the testing process.

5、Compact Structure: As a small-sized device, it occupies minimal space and is easy to move and install.

6、Multi-functionality: The chamber can be programmed according to different requirements, enabling the switching between various test modes.

1、Operational Guidelines: Before use, carefully read the manual to understand the device's performance, operating methods, and safety precautions.

2、Parameter Settings: Set the temperature and humidity parameters according to the test requirements, and check if the equipment is functioning normally.

3、Sample Preparation: Prepare suitable samples based on the testing needs, considering the size, weight, and other parameters to ensure that samples do not touch or collide with each other, which could affect the device's normal operation.

4、Monitoring and Recording: During the test, regularly observe the working condition of the equipment, record the temperature, humidity, and other parameters within the chamber, as well as any changes in the samples.

5、Maintenance: After the test, promptly clean any residues in the chamber, inspect and maintain the equipment, and turn off the power.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia