In the field of modern industrial production and scientific and technological research and development, the protective performance of products is crucial. Whether it is electronic equipment, mechanical equipment or other types of products, they need to maintain stable performance and reliable operation under different environmental conditions. Among them, dustproof ability is a key protection index, and IP5X test chamber has become an important tool to evaluate the dustproof performance of products.

First of all, the dustproof rating of IP5X means that the product can prevent solid foreign bodies with a diameter greater than 1mm from entering the inside of the equipment, and can not affect the normal operation of the equipment.

Second, the dust test chamber IP5X dust class is a standard in the international Protection class (Ingress Protection, referred to as IP class), which is used to describe the protection ability of electronic equipment against solid particles (such as dust). In IP5X tests, the dust used is usually dry talc, with the following size limits:

- Wire diameter: 50 microns (μm)

- Screen size: 75 microns (μm)

In the IP5X dust test, the amount of talc is usually 2kg/m³. These dust should be filtered through metal square holes before testing to ensure that the particle size of the dust meets the above standards. This size limit is designed to simulate the size of dust particles that may be encountered in the natural environment, so as to evaluate the dustproof performance of the equipment in actual use.

The IP5X test requires that the equipment is not completely protected from dust entry, but the amount of dust entering the equipment must not affect the normal operation and safety of the equipment. This means that while a small amount of dust may enter the inside of the device, this dust is not enough to cause damage to the device or affect its performance.

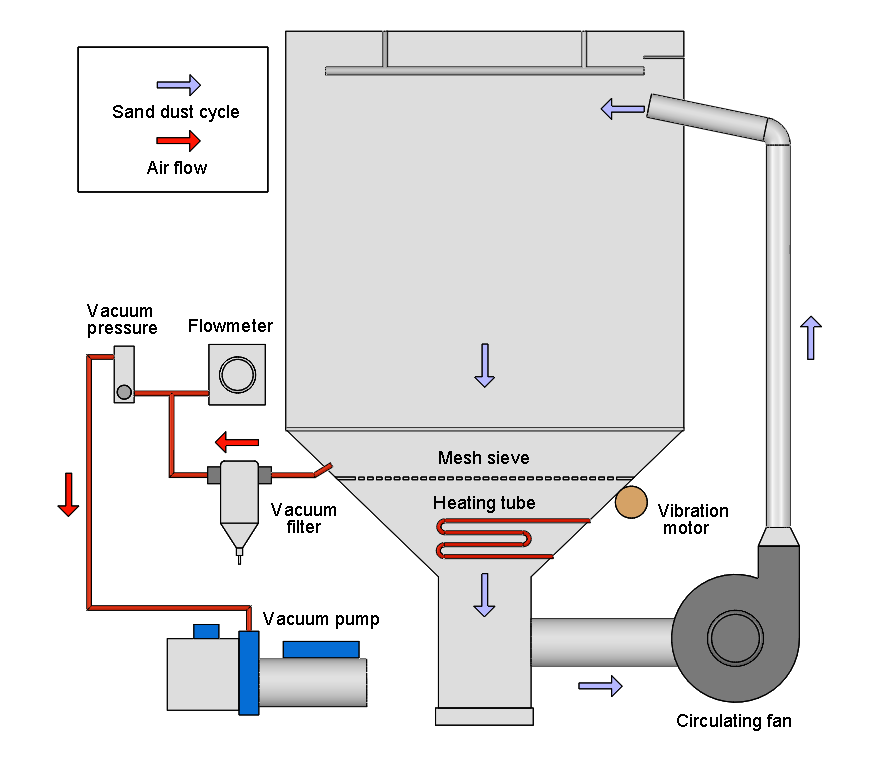

The operating principle of the IP5X test chamber is based on a specific dust injection and circulation system. Inside the test chamber, there is a special dust injection device, which can uniformly spray the specific particle size and concentration of dust into the test space.

At the same time, the inside of the test chamber is also equipped with a circulating air duct and a filtration system to ensure that dust can be fully circulated in the test space, and maintain a certain concentration and uniform distribution. During the test process, the tested product is placed in the test chamber, and after the specified time and conditions, the product is taken out for inspection to assess whether there is dust intrusion inside and the extent of intrusion.

Dustproof seal is one of the core elements of the IP5X test chamber to achieve accurate testing. In order to ensure that the dust environment inside the test chamber is not disturbed by external interference, the chamber structure of the test chamber must have good sealing performance.

First, the doors and observation Windows of the test chamber are usually sealed with special materials, such as rubber seals or silicone seals, to prevent dust from leaking through the door and window cracks. Secondly, the inlet and outlet of the test chamber and the connection parts also need to use sealing measures, such as gaskets, sealant, etc., to ensure that the entire test chamber maintains a high degree of tightness during operation.

In addition, in order to further improve the sealing effect, some advanced IP5X test chambers also use negative pressure sealing technology. By forming a certain negative pressure inside the test chamber, the external air can not easily enter the test chamber, so as to effectively prevent the leakage of dust and the influence of external factors on the test results.

Here is the "Part 4" content that has been regenerated for you:

4. Factors affecting test accuracy and coping strategies

It is not easy to achieve accurate testing of the IP5X test chamber, and there are many factors that can affect the accuracy of the test.

First, the uneven distribution of dust mass and particle size can lead to bias in test results. Different sources and types of dust may differ in physical properties, and failure to ensure that the dust used in each test is consistent and standard will affect the accuracy of the test. In this regard, dust of specific specifications and quality should be selected in strict accordance with the standard, and the dust should be evenly mixed and screened before each test.

Secondly, the stability of the air flow inside the test chamber is also a key factor. Unstable air flow may cause uneven dust distribution, resulting in high or low dust concentration in some areas, which affects the real situation of the product by dust. In order to solve this problem, it is necessary to optimize the design of the air duct inside the test chamber, and adopt more advanced fans and air regulating devices to ensure that the air flow in the chamber is smooth and uniform.

In addition, the installation method and location of the test product can also affect the results. If the product is improperly placed in the test chamber, local obstruction or interference may be formed, affecting the normal deposition of dust. Therefore, before testing, the correct installation method and position should be determined according to the characteristics and standard requirements of the product, and the consistency of each test should be maintained.

Through in-depth understanding and effective response to these influencing factors, the test accuracy of IP5X test chamber can be significantly improved, and a more reliable basis for the dustproof performance evaluation of products can be provided.

The IP5X test chamber is widely used in many industries and fields, providing an important guarantee for the quality and reliability of products.

1. Electronics industry

In the production of electronic equipment, such as mobile phones, computers, tablets, etc., dustproof performance is directly related to the service life and stability of the equipment. The test of the IP5X test chamber can ensure that the electronic equipment can still work properly in the harsh dust environment.

2. The automotive industry

Auto parts, especially key components such as engines and electronic control units, need to have good dust resistance. The IP5X test chamber can perform rigorous dust testing on auto parts, improving the overall quality and reliability of the car.

3. Aerospace

Aerospace equipment is exposed to a variety of harsh environmental conditions during flight, including large amounts of dust. The IP5X test chamber can simulate and test aerospace equipment to ensure that its dust resistance at high altitude meets the requirements.

4. Machinery and equipment industry

All kinds of mechanical equipment, such as industrial robots, CNC machine tools, etc., may be exposed to a large amount of dust during the work process. Through the test of IP5X test chamber, the dustproof ability of mechanical equipment can be evaluated, which provides a basis for the design and improvement of equipment.