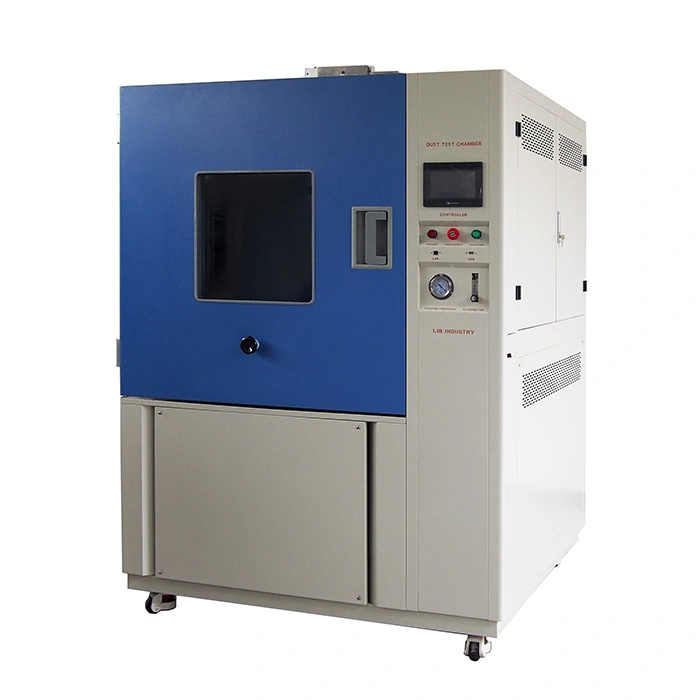

Features and Benefits of IP6X Test Equipment

1. Highly accurate simulation of a variety of harsh dusty environments, in accordance with IEC 60529 standard, to ensure that the test results accurately reflect the dustproof performance of the product.

2. The IP6X test equipment is well sealed, and the door is sealed with double silicone strips and other sealing materials to ensure that dust will not leak into the test area from the door crack and other parts during the test.

3. A large area observation window, and gloves can also be customized on the door, which is convenient for the tester to observe the internal test situation and flip the test parts during the test.

4. Set different control modes according to different test requirements, such as continuous dust blowing, periodic dust blowing, vibration time, preset test time, etc.

Specifications of IP6X Test Equipment

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

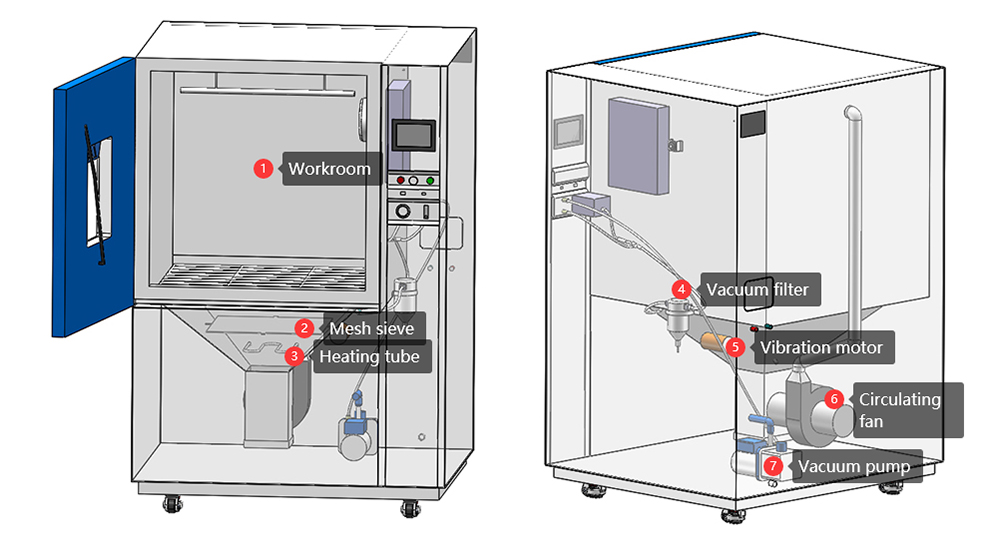

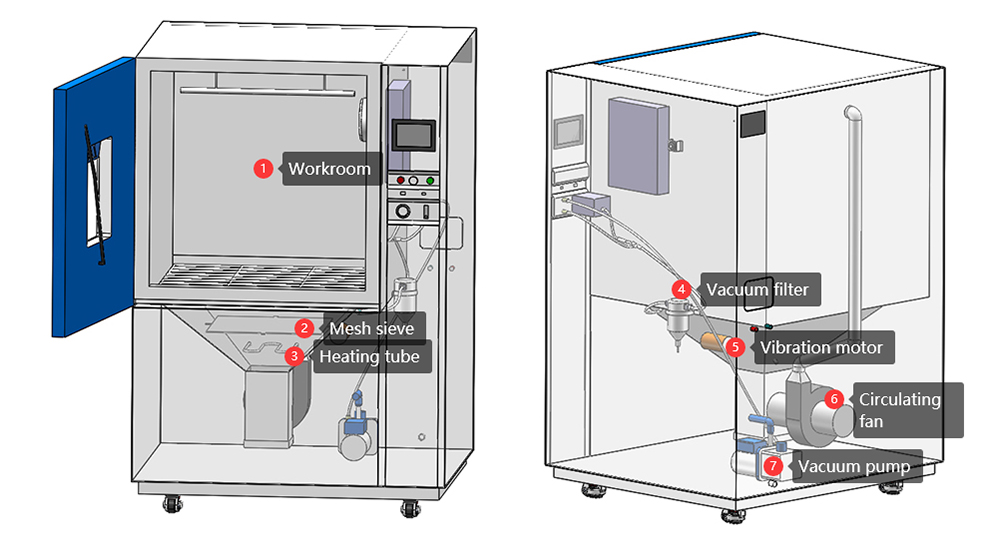

Configuration of IP6X Test Equipment

① Workroom | The internal material is SUS 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion; It comes with a hanging sample rack and lighting There is a dust outlet at the top of the workroom, and the circulating fan forms a vertical dust circulation system.

|  |

② Mesh sieve | |  |

③ Heating tube | Adjust the temperature in the test chamber, temperature range (ambient temperature to +50℃). Moisture dust can also be heated.

|  |

④ Vacuum filter | Filter impurities, dust and other pollutants that may be generated during the test to prevent them from entering key equipment such as vacuum pumps and affecting the normal operation of the equipment. |  |

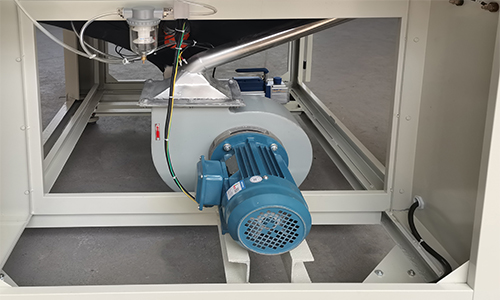

⑤ Vibration motor | The vibration motor can be used to simulate the vibration that the equipment may be subjected to during actual use, and shake away the dust stuck to the inner wall of the workroom. |  |

⑥ Circulating fan |

|  |

⑦ Vacuum pump | The air in the test part is extracted through the vacuum pump to form a certain vacuum degree, and the dustproof performance of the equipment is tested. |  |

............................................................................................................................................................................................................................

Features and Benefits of IPX8 Test Equipment

1. Equipped with a complete intake control system, and the internal test pressure can be accurately controlled through a high-precision pressure sensor, which can simulate the water pressure environment of 0-50 meters under different water depths.

2. Made of 304 stainless steel, with good corrosion resistance and wear resistance. The cylindrical container design has uniform stress distribution and can withstand greater pressure.

3. Equipped with safety valves, when the internal pressure exceeds the set value, the pressure can be automatically released to ensure the safety of the test process, and avoid the injury.

4. The sealing performance between the tank lid and the tank body is excellent, the use of silicone sealing ring and other high-quality sealing materials, good elasticity, not easy to age, can effectively prevent water leakage.

Specifications of IPX8 Test Equipment

Model | R78-600 |

Internal Dimension (mm) | Diameter 600mm * Height 1500 mm |

Overall Dimension (mm) | Diameter 800mm * Height 1800 mm |

Pressure | 50m water depth pressure |

Open mode | Pneumatic lid |

Material | A3 steel plate, wall thickness 15mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Storage water tank, Automatic water supply |

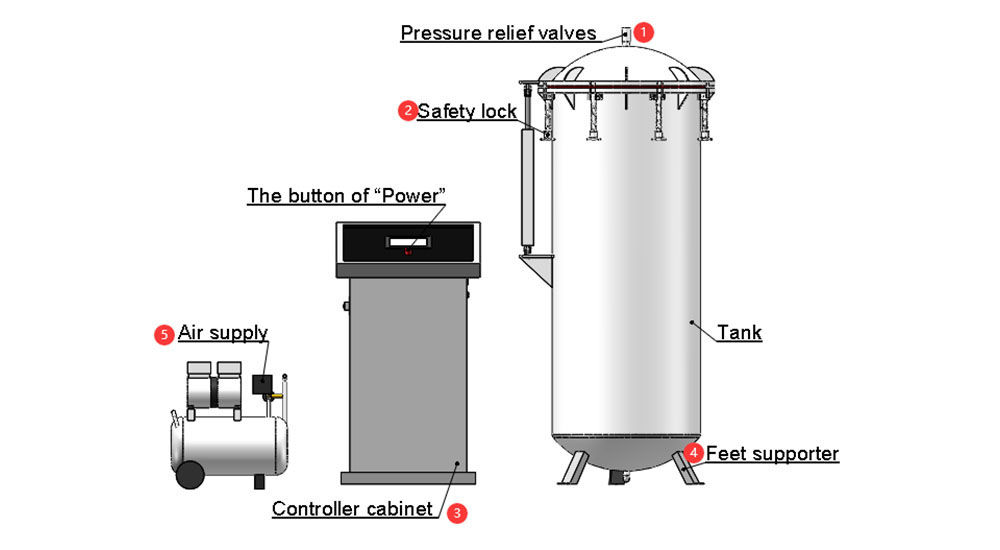

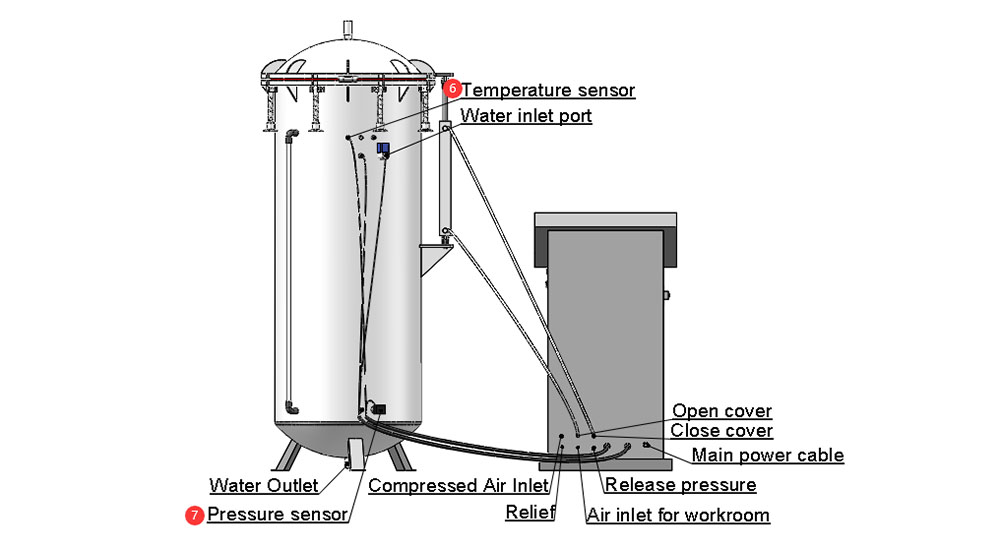

Configuration of IPX8 Test Equipment

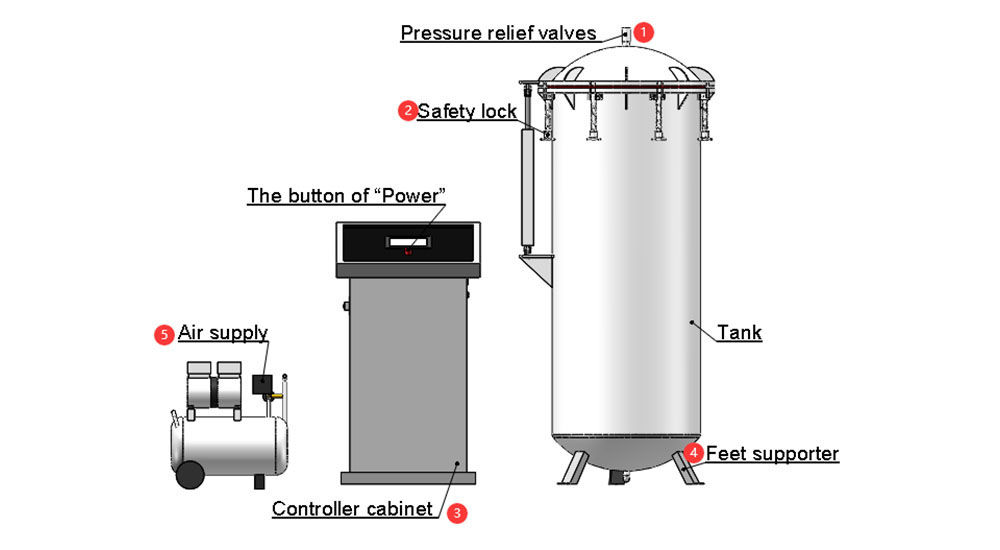

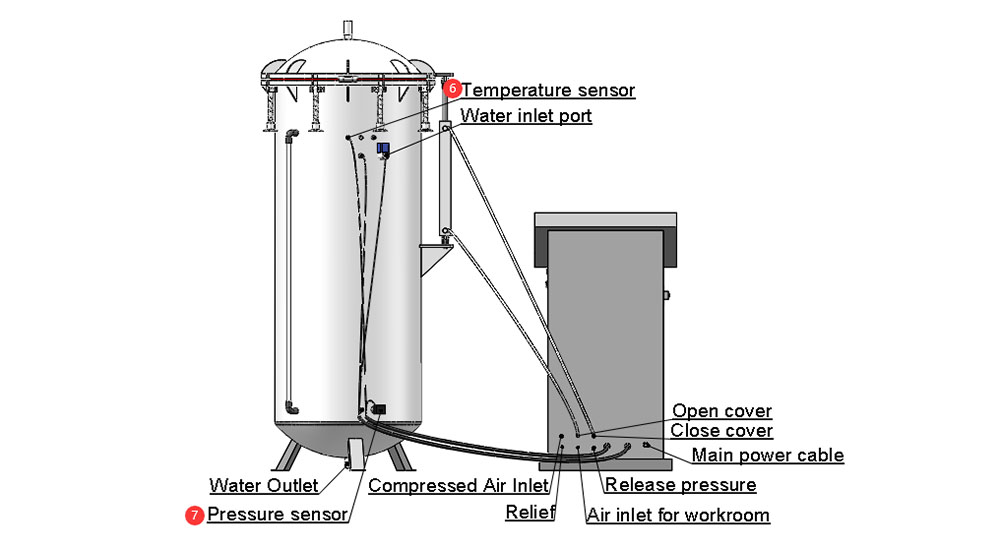

① Pressure relief valve | When the pressure exceeds the set safe value, the pressure relief valve will automatically open to release excessive pressure to prevent the internal pressure of the equipment from being too high. |

② Safety lock | 12 manual safety locks. Prevents the door or cover of the device from being accidentally opened to avoid internal water, gas or pressure leakage during testing. |

③ Controller cabinet | Test parameters can be set, such as test pressure, test time, temperature, etc., and the operating status and test data of the device can be displayed in real time. |

④ Feet supporter | Adequate strength and stability for supporting and fixing IPX8 test equipment. |

⑤ Air supply | Air is needed to apply pressure or perform operations such as gas leak detection. |

⑥ Temperature sensor | Measure the temperature inside the IPX8 test equipment or the test sample. |

⑦ Pressure sensor | Real-time monitoring of pressure changes inside IPX8 test equipment. |

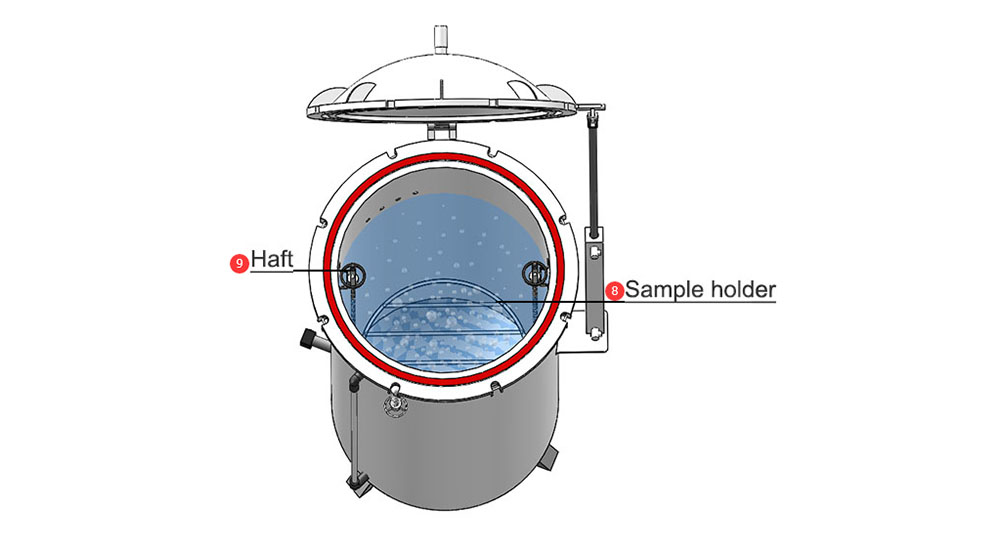

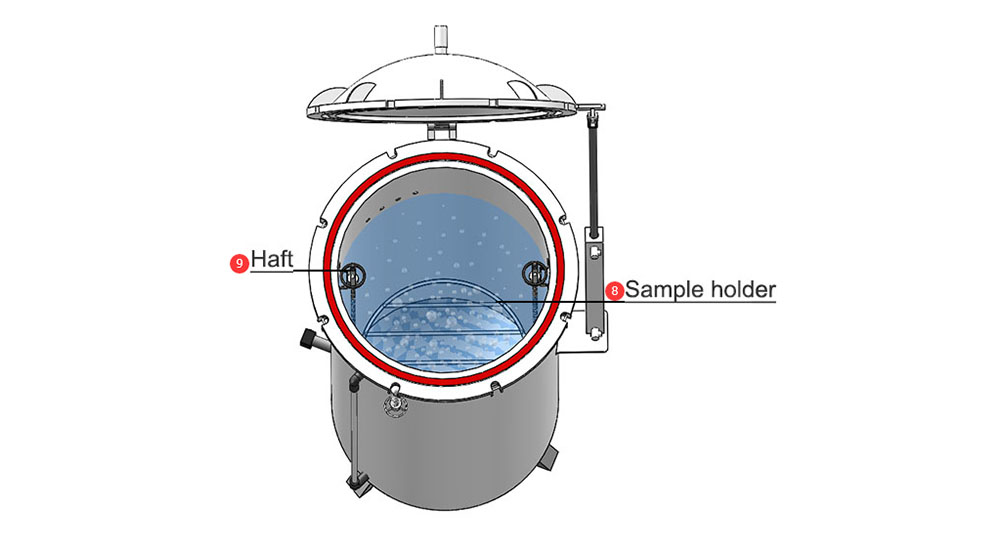

⑧ Sample holder | Place the test sample, bearing 50KG. |

⑨ Haft | Sample holder can aligned on both sides of the haft. |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español