Features and Benefits of IPX4 Water Test Chamber

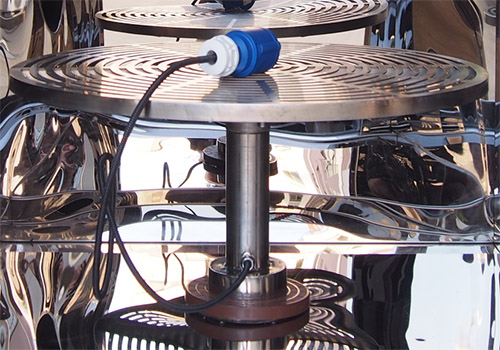

1. Oscillating tube is made of stainless steel and available in various diameters, spray nozzle is detachable special nozzle.Oscillating tube range can be reached to ±45°, ±60°, ±90°, ±180°, accurate and stable spray flow rate of 0.07L/min per hole.

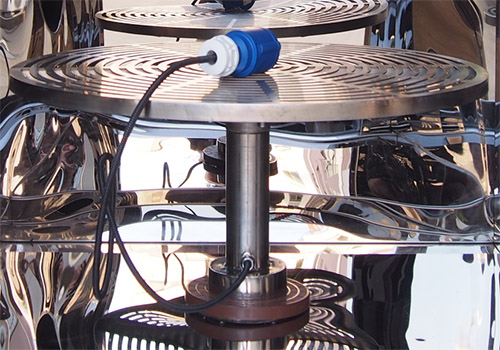

2. The speed, angle and height of the sample turntable can be set on the controller, and the positive and negative rotation can be automatically controlled. And the electrical part is fully sealed to prevent water leakage.

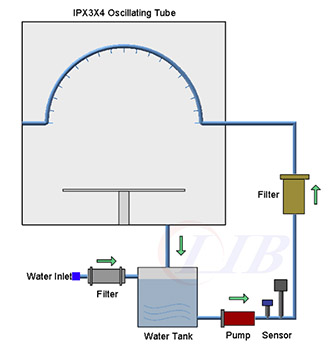

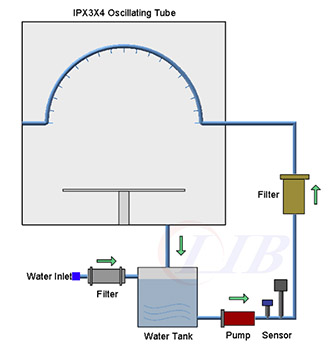

3. Circulating water system: Automatic inlet filtration system filters impurities in 0.03mm particles to improve test efficiency and convenience. The water circulation system greatly reduces water consumption.

4. The water tank of LIB Industry ipx4 waterproof test chamber is equipped with water level float ball valve, with high and low water level alarm detection function, which can effectively prevent the water pump from being damaged.

Specifications of IPX4 Water Test Chamber

Model | R-800C | R-1200C |

Internal Dimensions (mm) | 900*950*950 | 1300*1350*1370 |

Overall Dimensions (mm) | 1180*1420*1920 | 1540*1820*2200 |

Useful Volume (L) | 810 | 2400 |

Oscillating Tube Radius | 400mm | 600mm |

Drip Tray Size | 600*600 | 1000*1000 |

Spraying Hole Diameter | φ0.4mm |

Hole Spacing | 50 mm |

Swing Angle of Oscillating Tube | 0 ~ ±180° (Adjustable) |

Turntable Rotation Speed | 1r/min (Adjustable speed) |

Water Pressure Control | Flow meter |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Water tank, booster pump, Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

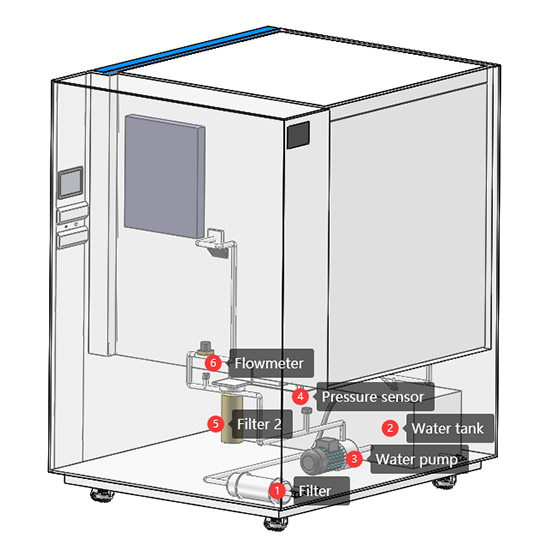

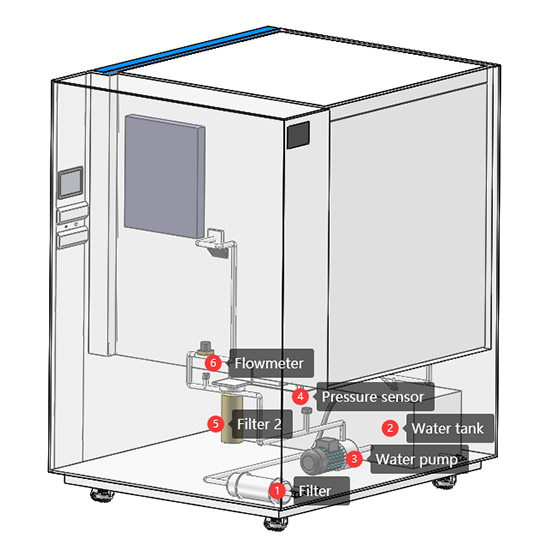

Configuration of IPX4 Waterproof Test Chamber

1. Filter:

It can be mainly used to filter various impurities in 0.03mm particles of water entering the test chamber to prevent impurities from causing wear and damage to key components such as pumps.

2. Water tank:

The water storage function provides sufficient water source for the rain test. Recycle water: Collect and treat the water after use, and recycle it again after filtration, purification and other operations.

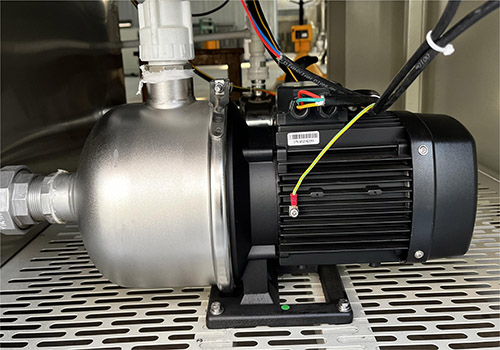

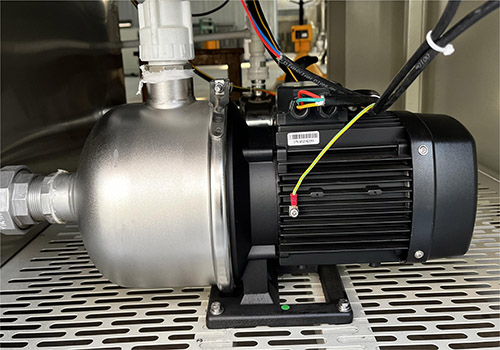

3. Water pump:

Provide power, so that water can be transported to the pendulum tube and nozzle and other parts through the pipe with a certain pressure and flow.

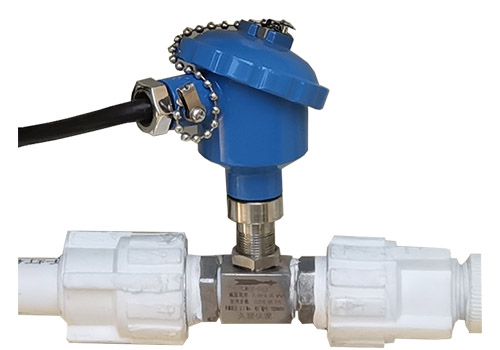

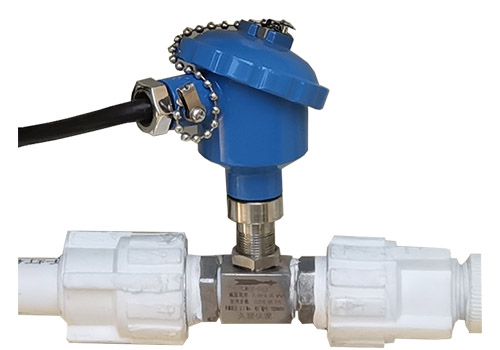

4. Pressure sensor:

The pressure value of the water flow during the test is measured in real time for timely adjustment and control.

5. Water circulation filter:

After the ipx4 waterproof test, the water is filtered twice to remove impurities, dirt and other pollutants caused by the test process. Improved water utilization.

6. Flow meter:

Accurately measure the flow of water during the test to ensure that the flow of water meets the standard requirements of IPX3 and X4 tests. Real-time monitoring of water flow changes.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español