With the vigorous development of the automobile industry today, the quality and reliability of automobiles have become the focus of consumers' attention, and are also the key factors for automobile manufacturers to stand out in the fierce market competition. Among them, the corrosion resistance of auto parts directly affects the service life, safety and appearance of the car. As a kind of test equipment specially used to simulate harsh corrosion environment, salt spray test machine plays a very important role in the automobile industry.

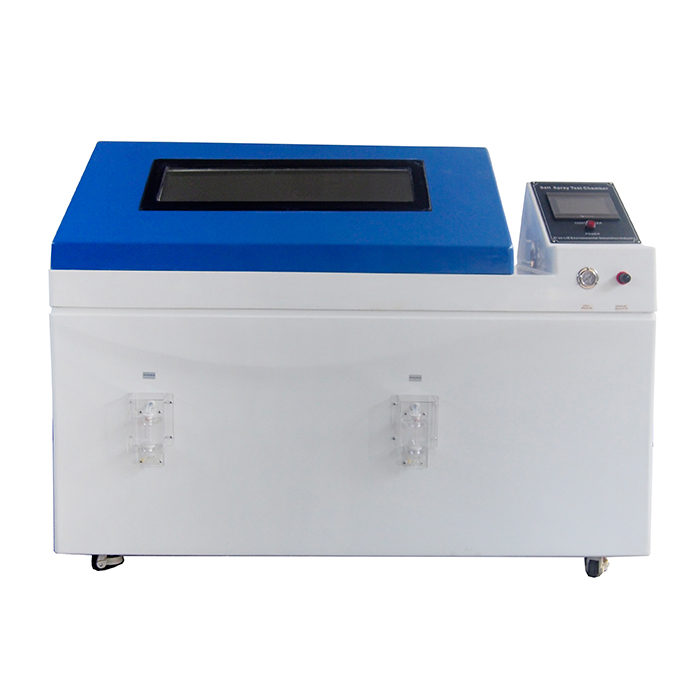

The working principle of salt spray test machine is mainly based on the accurate simulation of salt spray environment. By atomizing a saline solution with a specific concentration, these tiny salt spray particles are evenly dispersed in the test chamber using compressed air. The environmental control system inside the test chamber accurately regulates key parameters such as temperature, humidity and the amount of salt spray deposition. In general, the temperature in the test chamber is usually set at about 35 ° C, and the humidity is kept at a high level to simulate the harsh environment of high humidity and high salt at the seaside or other places. In such an environment, the salt spray particles react chemically with the surface of the auto parts, thus accelerating the corrosion process in order to assess the corrosion resistance of the parts in a relatively short time.

As an important part of automobile body, its metal parts such as body shell and frame need to have good corrosion resistance. The salt spray test equipment can simulate the corrosion factors faced by the car body in the actual use environment, such as road salt, moisture and industrial pollution. Salt spray corrosion testing of metal body parts can accurately evaluate the corrosion resistance of different materials and surface treatment processes.

For example, some automobile manufacturers found in the test that the performance of the body steel plate after special galvanized treatment in the salt spray test is significantly better than that of the ordinary steel plate, which provides an important basis for the selection of body materials and protection process optimization, so as to effectively extend the service life of the body and reduce the maintenance cost and safety risks caused by corrosion.

Fasteners and connectors on the car, such as bolts, nuts and solder joints, although the volume is small, their reliability plays a crucial role in the safety of the vehicle. In the salt spray environment, these parts are prone to corrosion, resulting in loosening, fracture and other failure modes.

The salt spray tester provides a targeted reliability assessment of these tight connections. By observing the corrosion of fasteners and connectors in the process of salt spray test, automotive engineers can find potential safety risks in time and take corresponding improvement measures, such as optimizing the material composition of fasteners, improving the surface coating process or adjusting the design of the connection structure, etc., to ensure that in the entire service life cycle of the vehicle, These key parts can maintain a stable and reliable connection state.

With the continuous improvement of the degree of automobile electronization, electronic components and electrical equipment are more and more widely used in automobiles. However, these electronic components are often less resistant to the environment, especially in the salt spray environment, electronic sensors, circuit boards, electrical control units, etc., are vulnerable to corrosion and failure.

The salt spray test machine can simulate the salt spray erosion that the car may encounter during the driving process, and detect the protective performance of electronic components and electrical equipment. For example, in the salt spray test, you can check whether the protective coating of the circuit board can effectively block the intrusion of salt spray, and whether the sealing performance of electronic components is good. Only the electronic components and electrical equipment that pass the salt spray test can ensure the stable operation of the automotive electronic system in harsh environments and avoid safety accidents caused by electronic failures, such as brake failure and engine control system failure.

In the automotive industry, salt spray testing follows a series of strict international and domestic standards. Internationally, ISO standards such as ISO 9227 specify salt spray test methods, equipment requirements and evaluation criteria for test results. The ASTM standard in the United States is also widely used in the salt spray test of auto parts, and the salt spray test chamber can also be called ASTM B117 chamber, which has developed corresponding test specifications for different types of parts.

Automotive companies usually develop more detailed internal test specifications and processes based on these standards, combined with the characteristics of their own products and market positioning. For example, some high-end automotive brands may increase the duration of salt spray tests or increase the severity of tests on top of standard requirements to ensure that their products have higher quality and reliability in terms of corrosion resistance.

In summary, salt spray test machine occupies an indispensable position in the automotive industry. From the working principle, it can accurately simulate the salt spray environment, and provide a reliable means for the corrosion resistance test of auto parts. In the automotive parts test application, it covers many key areas such as body metal parts, fasteners and connectors as well as electronic components and electrical equipment, which provides a strong guarantee for ensuring the overall quality and safety of the vehicle. The strictly followed test standards and specifications make the salt spray test results authoritative and comparable, providing a unified scale for the quality control of the automotive industry.

The contribution of salt spray test machine to the quality improvement of automotive products is reflected in many aspects, helping material research and development innovation, optimizing production processes and enhancing market competitiveness, and ultimately promoting the development of the entire automotive industry. Looking forward to the future, with the continuous progress of automotive technology, such as the rise of new energy vehicles, the development of autonomous driving technology, auto parts will face a more complex and changeable use environment, salt spray testing technology will continue to innovate and improve, its application field will be further expanded, continue to play an important role in the high-quality development of the automotive industry on the road.