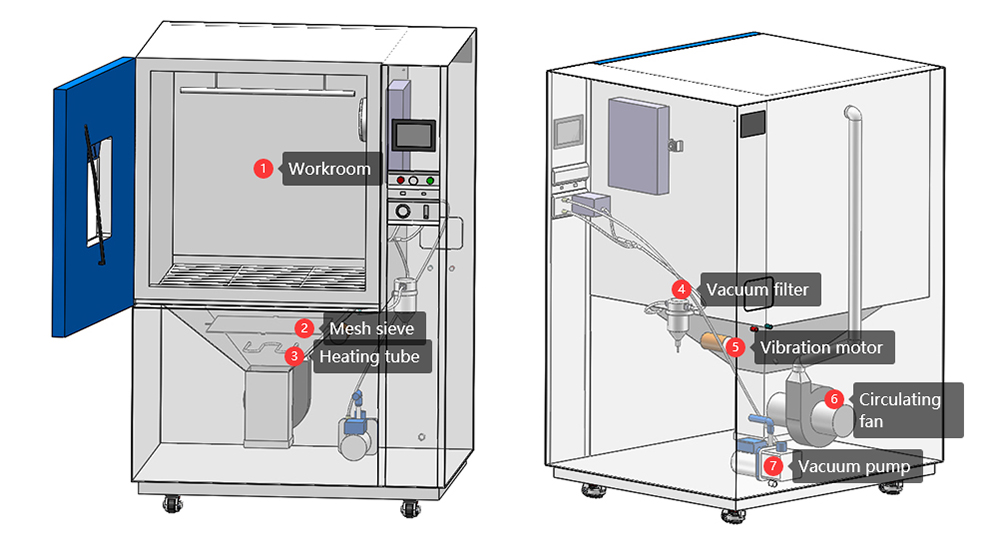

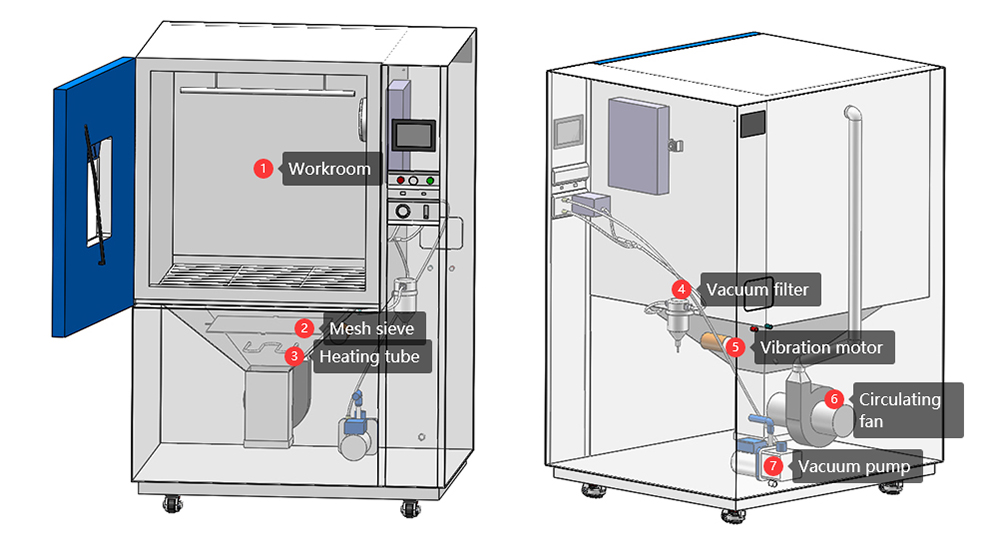

Features and Benefits of IP6X Test Equipment

1. The workroom adopts double-layer sealing rubber, and is equipped with electromagnetic lock to prevent the operator from misoperation, to ensure no dust leakage during the test process, and to ensure the safety of operators and clean test site.

2. 50μm talc powder is used to simulate sand dust, and the dust concentration is 2kg ~ 4kg/m³. The workroom circulates air, and the dust forms a vertical 0-shaped circulation system to simulate an uninterrupted dust environment.

3. The door of LIB Industry ip6x test equipment is equipped with a transparent observation window with a wiper to facilitate the observation of product status during the test process, and custom gloves can also be made on the door to facilitate direct contact and adjustment of the product.

Specifications of IP6X Test Equipment

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

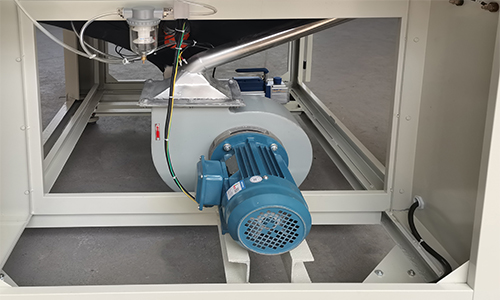

Configuration of IP6X Test Equipment

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español