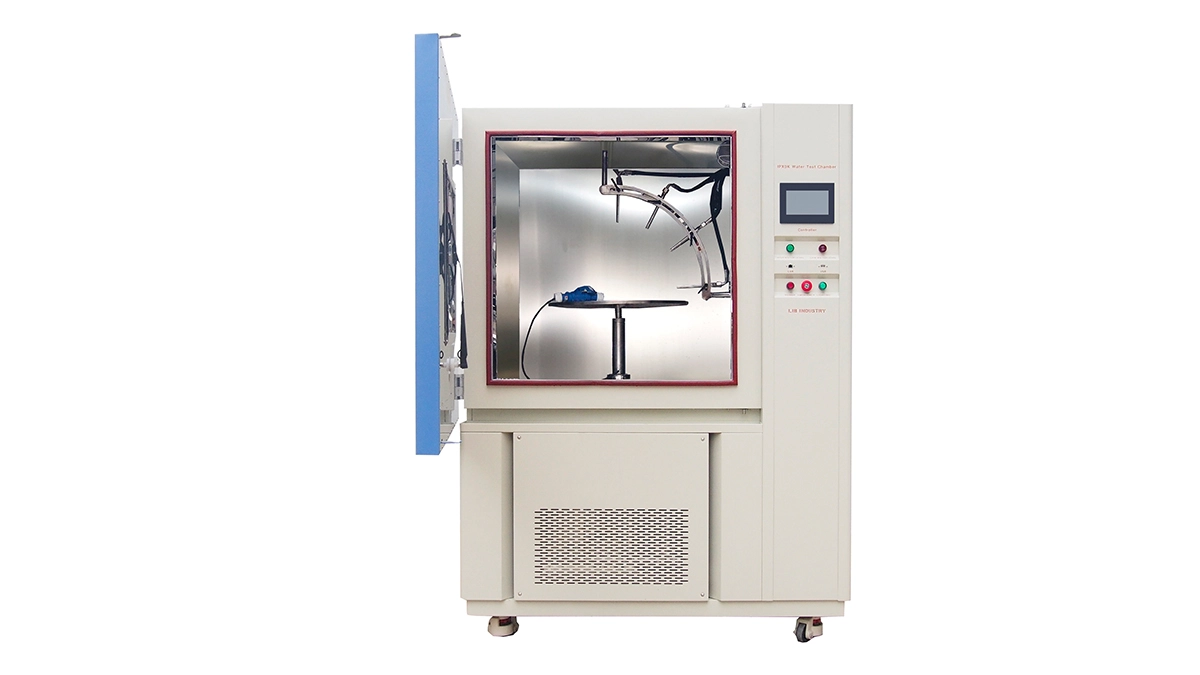

Thermal chamber is a kind of environmental thermal chamber used to simulate various temperature environments. It can precisely control the temperature within a set temperature range and maintain stable temperature conditions for performance testing, reliability assessment, environmental adaptability studies, etc., of products, materials or components. Through the thermal test chamber, extreme high temperature, low temperature and temperature changes can be simulated to investigate the reaction and performance of the tested object in different temperature environments.

Thermal chamber is suitable for high temperature and low temperature reliability test of industrial products. The components and materials of electronic and electrical products, automobiles and motorcycles, aerospace, ships and weapons, colleges and universities, scientific research institutions and other related products are tested under the condition of high temperature and low temperature (alternating) cycle changes. The thermal cycling test chamber have a wide temperature control range from -70 ℃ to +150 ℃, and the products comply with IEC 60068, MIL and other standards.

Understand its working principle from the core functions of the thermal cycling test chamber:

refrigeration system is one of the core of the comprehensive thermal cycling test chamber. The refrigeration method of the environmental test chamber is mechanical refrigeration, mechanical refrigeration adopts steam compression refrigeration, which is mainly composed of compressors, condensers, throttling mechanisms and evaporators, and adopts cascade refrigeration. The refrigeration system of the LIB environment temperature chamber is composed of two parts, respectively called the high temperature part and the low temperature part, each part is a relative refrigeration system. The evaporation of the refrigerant in the high temperature part absorbs the heat from the low temperature part of the refrigerant and vaporizes; The evaporation of the cryogenic part of the refrigerant absorbs heat from the object being cooled (the air in the temperature cycling test chamber) to obtain the cold amount. The high-temperature part and the low-temperature part are connected by an evaporative condenser, which is both the condenser of the high-temperature part and the condenser of the low-temperature part.

The principle of the heating system of the thermal chamber is relatively simple, composed of high-power resistance wire, which can ensure a higher heating rate. There are 10cm thick polyurethane foam and insulation cotton around the workroom, which makes the temperature in the working room hotter; and which can obtain better insulation performance, resistance to degradation, environmental protection, reduce noise.

the control system is like the brain of the thermal chamber, PID controller as the main control unit, the various parts of the equipment for command, operation, detection and redistribution, in order to achieve the maximum effective use; temperature control using P.I.D. S.S.R. system synchronous coordinated control, can improve the stability and life time of control components and interfaces. Screen display function is using LCD display, can display the test conditions (including temperature segment, cycle number, running time, remaining time, etc.).

As the most important parameter in the thermal test chamber, temperature, there are related temperature indicators, which can let us better understand the performance of the thermal test chamber.

It is also called temperature stability, control temperature stability, at any given time interval, the difference between the highest and lowest temperature at any point in the working space. There is a slight difference here: "work space" is not "work room", it is a space about 1/10 of the length of each side of thethermal cycling test chamber workroom wall. This index assesses the control technology of the thermal chamber.

It refers to the limit temperature that the thermal test chamber workroom can tolerate and (or) can reach. Temperature range usually contains the concept of being able to control constancy, which should be an extreme value that can operate stably for a relatively long time. General temperature range includes extreme high temperature and extreme low temperature. The general standard requires the index to be ≤1℃ or ±0.5℃.

The maximum difference between the mean temperature values of any two points in the work space at any time interval after temperature stabilization. This index can better assess the core technology of the product than the temperature deviation index below. The general standard requires indicators to be ≤2℃.

After the temperature is stable, at any time interval, the average temperature of the center of the work space in the thermal chamber and the average temperature of other points in the work space difference. The general standard requirement index is ±2℃, and the pure thermal chamber can be above 150℃ according to the actual use ℃ ± 2%.

Thermal chamber is widely used in many industries. Whether it is plastic, electronics, food, clothing, or vehicles, metals, chemicals, building materials and other industries, it is necessary to use the equipment for reliability testing of products. For example, the performance stability of electronic products at extreme temperature, the storage life of food under different temperature conditions, temperature test chamber provides a specific temperature environment for various types of scientific research to assist the development of related research, can be tested by thermal cycling test chamber.

1. High temperature test

Evaluate the performance, reliability and stability of the product in a high temperature environment, such as the heat resistance of the material and the high temperature working ability of electronic equipment.

2. Temperature cycle test

Through repeated temperature increase and decrease cycles, to investigate the product's tolerance to temperature changes and possible fatigue, damage and other conditions.

4. Thermal aging test

Accelerate the aging process of the product to understand its long-term performance trend in the thermal environment.

5. Heat shock test

Test the resistance of the product to sudden temperature changes.

The above is the introduction of the thermal chamber, if you want to know more information, click here to view the temperature test chamber details.

If you need professional help and solutions, please contact us inquiry@libtestchamber.com, professional team is online.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia