Freeze Resistance Test Chamber Features and Benefits

1. Mechanical refrigeration unit, adopts cascade refrigeration mode, high refrigeration efficiency and stable refrigeration.

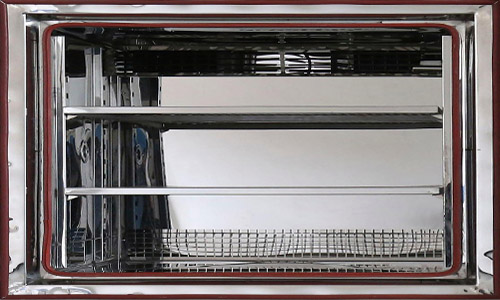

2. A conductive film is attached to the inside of the observation window of the workroom to prevent frost formation from affecting the test monitoring.

3. Bench, vertical, walk-in freeze resistance test chamber are available, according to your experimental needs, workroom size, test chamber performance can be customized.

4. The freeze resistance test chamber can be connected remotely to receive signals and data, and the location of data analysis is not limited.

Freeze Resistance Test Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

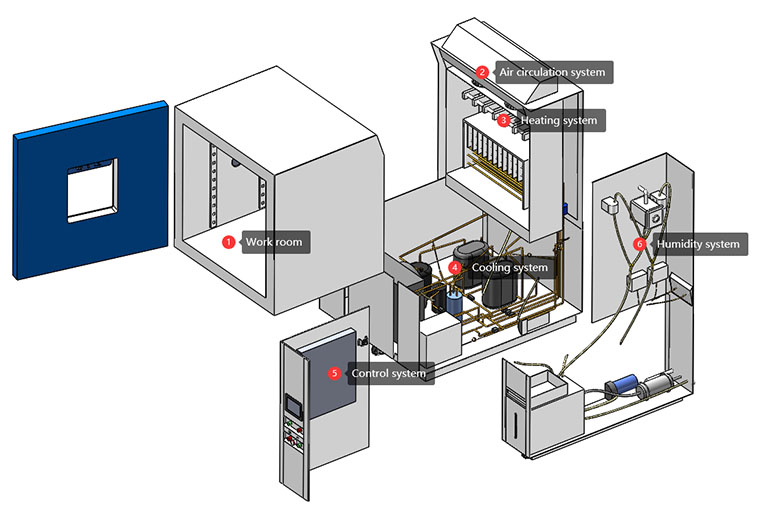

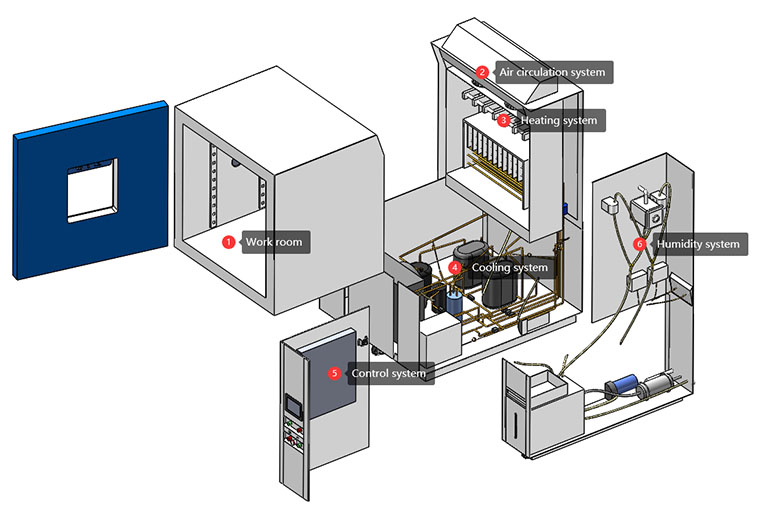

Configuration of Freeze Resistance Test Chamber

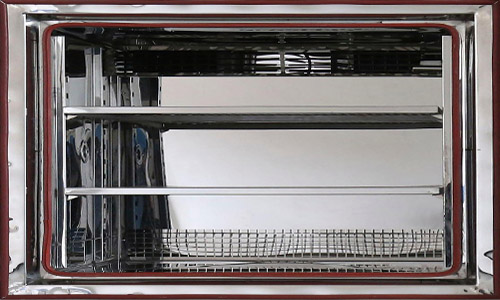

① Workroom | 304 stainless steel, suitable for low temperature, high humidity test environment. 10CM thick insulation layer, help accurate temperature control.

|

|

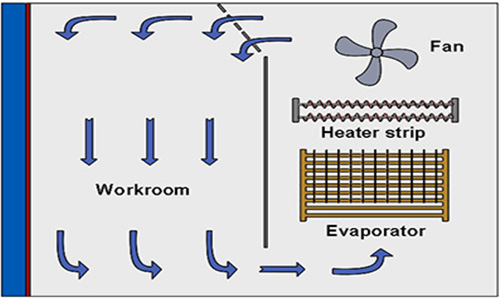

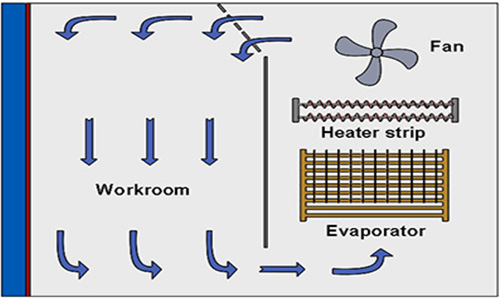

② Air circulation system | To promote the air circulation in the workroom, the hot and cold air will be evenly dispersed, and the reliability and repeatability of the test results will be improved. |

|

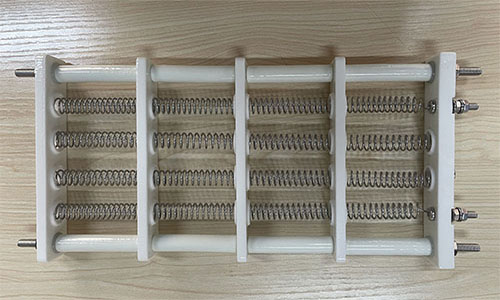

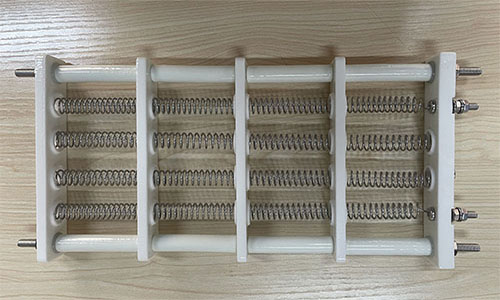

③ Heating system | The nickel-chromium alloy heating wire can quickly increase the temperature with 3℃/min heating rate, which can meet the complex and changeable test temperature requirements. |  |

④ Cooling system | Compressor, condenser, evaporator, throttling device cooperate with each other, fast cooling, to meet the needs of low temperature environment test. |

|

⑤ Humidity system | Humidification function can be customized, evaporation humidification, humidity 20%~98%RH adjustable. |

|

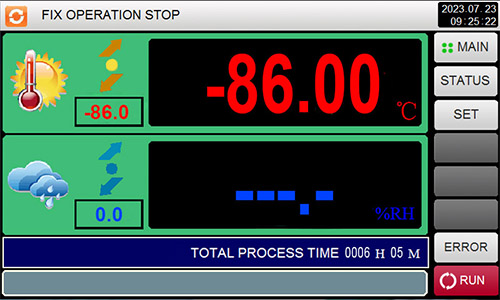

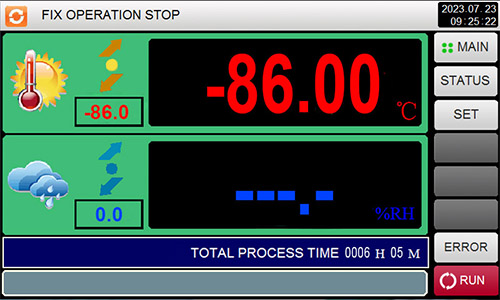

⑥ Control system | PLC controller has programming and storage functions, can flexibly set the temperature, humidity change program, to meet the needs of diverse scientific research projects. |

|

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español