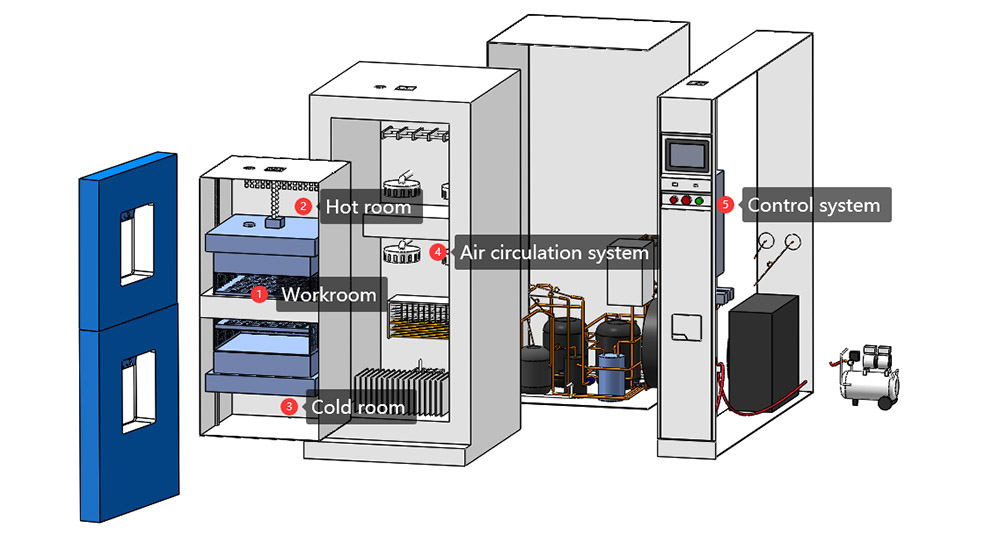

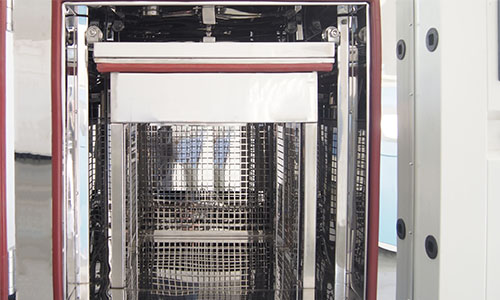

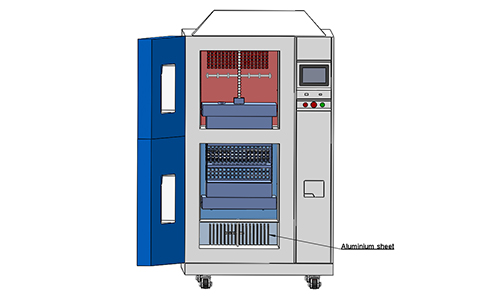

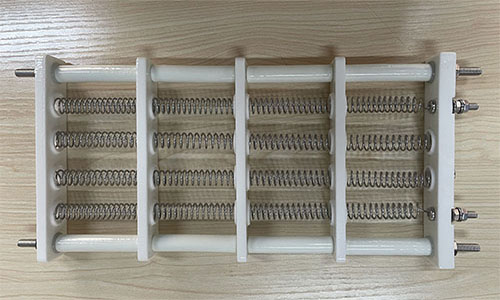

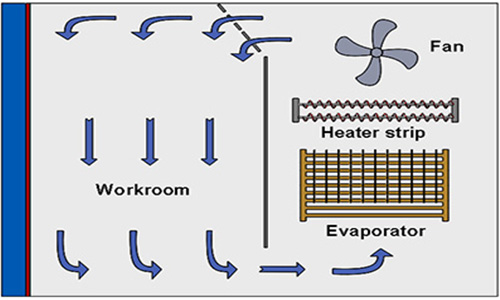

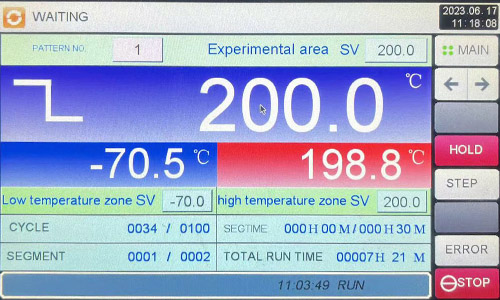

LIB hot and cold shock chamber can make products or material undergone extreme temperature variation from -70 ℃ to +220℃ within 3 seconds. The specimen is transferred through cold room and hot room vertically by basket.

Various types of temperature hot and cold chamber can be customized, air to air, air to liquid, liquid to liquid, etc., welcome to get a quote!

Model: TS-162, TS-340, TS-500, TS-1000

Standard: AAMA501, ASTM D4169-16, IEC 61215, IEC 61646, IEC61108, IEC62688, MIL-STD-813D

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español