In the era of rapid technological advancement, various products are everywhere in our daily lives, and waterproof performance has become one of the important indicators for evaluating product quality and reliability. Whether it is electrical equipment working in a humid environment, the electronic products we carry every day, or the equipment used for outdoor exploration, good waterproof performance can ensure their normal operation, prolong their service life, and safeguard the safety and convenience of users. That is why the water immersion tank, a key tool for evaluating product waterproof performance, plays a vital role.

The immersion tank mainly tests the waterproof rating of IPX7 and IPX8. IPX7 means that the product can withstand immersion in water at a depth of 1 meter for a short period of time (usually 30 minutes) without being damaged. IPX8 represents a higher level of waterproof capability, and products can be submerged underwater under specific conditions, with the depth and duration of immersion depending on the design and requirements of the product.

To accurately simulate these waterproof scenarios, the water immersion tank employs a series of advanced technologies and designs. The key to water pressure control is the precise pressure regulation device, which enables the water immersion tank to generate water pressure that is consistent with the actual environment, ensuring that the pressure applied to the product is accurate. The setting of immersion time strictly follows the IEC 60529 standard requirements to accurately evaluate the product's waterproof performance within the specified time.

1. Material and Design

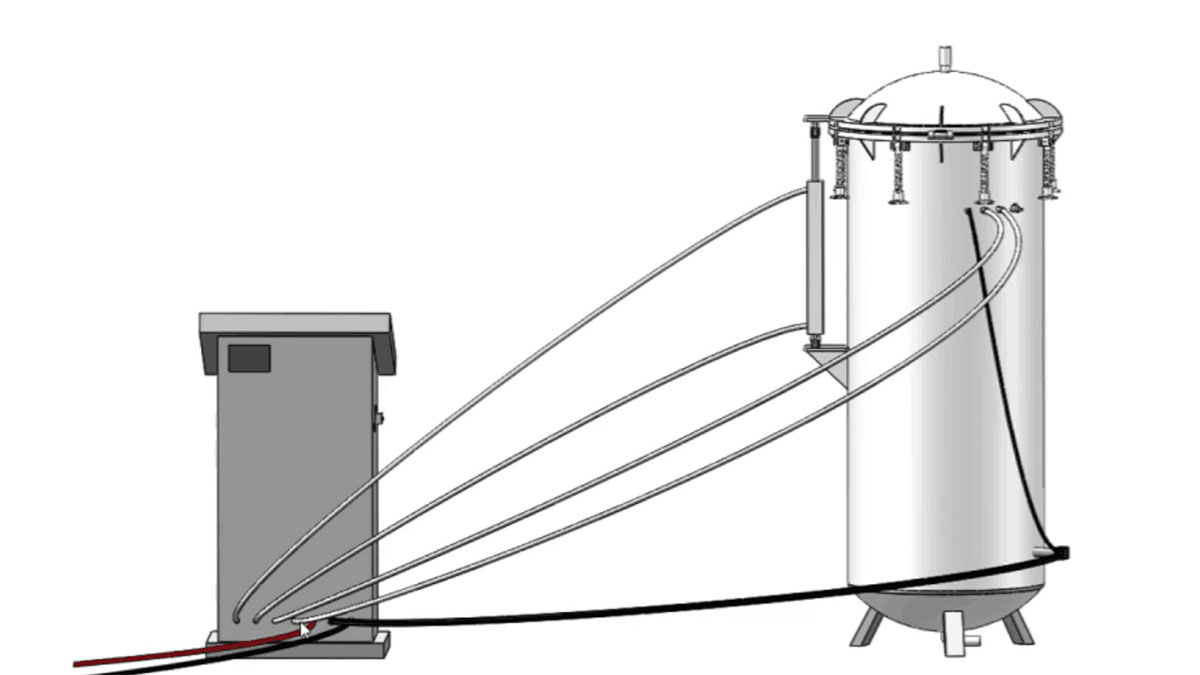

The water immersion tank is made of high-strength corrosion-resistant materials SUS 304 to withstand water pressure and long-term use. The top of tank is locked by lid lock.The high-strength manual pressure locks can guarantee the tank’s good tightness, ensuring no water leakage during the test.

2. Control System

Accurate parameter setting and monitoring are the core functions of the control system. Operators can easily set water pressure, water temperature, and immersion time parameters through the intelligent control panel and monitor real-time data during the testing process. The automated operation flow greatly improves testing efficiency, reduces human error, and ensures the accuracy and repeatability of the test results.

The controller controls the opening and closing of the water immersion tank, deflates and inflates the tank, and connects sensors, including pressure sensors and temperature sensors.

3.Safety System

The safety fixing device is an important part to ensure the stability and safety of the water immersion tank during use.There are three M8 hole Z-shaped tripod at the bottom of the cylindrical water tank, which has good grip and prevents water immersion tank from shaking or displacement during operation by tightly connecting the bottom of the test box to the mounting ground.

Pressure limiting protection is a protection mechanism set up to prevent the internal pressure of the water immersion tankfrom exceeding the safe range. During the immersion test, if the pressure inside the tank increases abnormally, it may cause equipment damage or even endanger the safety of the operator. Pressure limiting protection usually uses a pressure sensor to monitor the pressure inside the chamber. When the pressure reaches the set upper limit, the system automatically takes measures, such as stopping the pressure, releasing the pressure, or sounding an alarm.

1. Electronic products

In the field of smartphones, tablets and smartwatches and other electronic products, the application of water immersion tank is very extensive. Consumers' demand for the use of these devices in humid environments is increasing, such as taking pictures with a mobile phone in the rain and using a tablet by the swimming pool. Through the rigorous testing of the test chamber, manufacturers can ensure that the products have sufficient waterproof performance to meet consumer needs.

2. Electrical equipment

Switchgear, lamps and other electrical equipment work in outdoor or humid industrial environments, and good waterproof performance is the key to ensuring their safe operation. The water immersion tank can help detect the sealing performance of the shell of these devices to prevent water from entering and causing short circuits, leakage and other faults.

3. Automotive parts

Sensors, headlights and other parts of cars are often exposed to harsh weather conditions and must have reliable waterproof performance. The water immersion tank can simulate the water immersion situation during car driving and conduct strict waterproof testing on these parts to improve the overall safety and reliability of the car.

4. Outdoor equipment For outdoor equipment such as action cameras and walkie-talkies, waterproof performance is an important guarantee for normal operation in extreme environments. The water immersion tank can provide accurate assessment of waterproof performance for these products, allowing users to travel without any worries in the outdoors.

1. Improve product quality and reliability

By conducting strict waterproof performance tests, manufacturers can identify defects in product design and manufacturing, and make timely improvements to enhance the overall quality and reliability of the product. Consumers can use products that have passed the test with greater confidence, reducing product damage and malfunctions caused by waterproof issues.

2. Comply with international standards and regulations

Many industries and regions have established relevant waterproof standards and regulations, and products can only enter the market for sale after passing the relevant tests. Using the water immersion tank can help enterprises ensure that their products comply with international standards and regulations, avoiding legal risks and economic losses due to non-compliance.

3. Reduce post-sales risks and costs

If products have problems with waterproof performance, they will result in a large number of post-sales repairs and returns, increasing the cost and reputation loss of the enterprise. By conducting tests in advance using the test chamber, the risk of post-sales problems can be effectively reduced and unnecessary costs can be saved.

Ⅴ. Conclusion

Water immersion tanks play a crucial role in ensuring the waterproof performance of products. Not only do they provide reliable testing methods for enterprises to improve product quality, comply with regulations, and reduce post-sales risks, but they also bring safer, more reliable, and more convenient usage experiences for consumers.

Above is the introduction to water immersion tank, what do you want to understand the water immersion test cases also please tell us, click https://www.libtest.com/products/water-immersion-test-chamber/ to learn more about the specifications of the water immersion tank. Please contact our team directly at inquiry@libtestchamber.com and we will get you the best quote and a tailor-made solution.