When you drive along the coastal highway and enjoy the sea breeze on your face, you may not think that your car is undergoing a corrosion test. But if automobile has not strictly carried out salt spray testing,may leading to the recall of tens of thousands of cars due to corrosion of metal parts caused safety risks.Using a salt spray test chamber for testing is vital.

Rust of metal parts cause more than 10 billion dollars in losses to the global automobile industry every year. Corrosion of the engine support may cause the power system to fall off, and corrosion of the brake caliper will reduce the brake sensitivity.

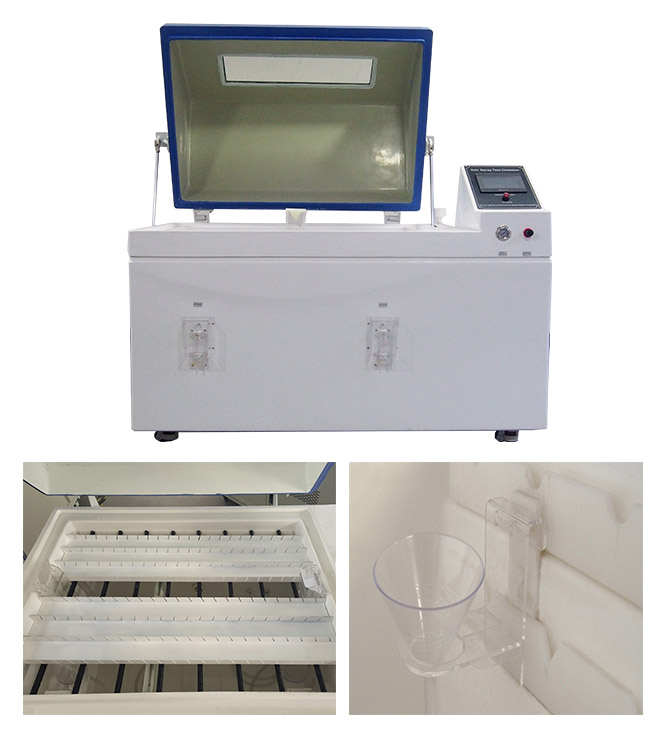

Model | S-150 | S-250 | S-750 | S-010 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 95% ~ 98% RH | |||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||

Spray Type | Continuous / Periodic | |||

Salt Fog Collected | Fog collector and fog measure cylinder | |||

Air Preheating | Saturated air barrel | |||

Spraying System | Atomizer tower and Spray nozzles | |||

Controller | PID controller | |||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||

Material | Glass fiber reinforced plastics | |||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||

| ||||

Intelligent constant temperature system: PID algorithm is used to achieve accurate temperature control of 35 ° C ±0.5 ° C, and the fixed mode temperature can meet most standard tests such as ASTM B117, and the temperature range is: room temperature ~60 ° C

Newly upgraded FRP material, one molding, no salt spray leakage, longer service life

Composite corrosion mode: Support the free combination of salt spray/dry/hot and humid modes

Energy saving and environmental protection: 40% energy saving compared with traditional equipment, wastewater recovery rate of 95%

Cloud data management: whole process data recording and storage

Beyond that, there are more customization options, sample holders, studio sizes, controllers, and more, with LIB creating a salt spray test chamber tailored to your needs. LIB provides free consultation customized solutions, please leave your requirements below, LIB will contact you as soon as possible.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español