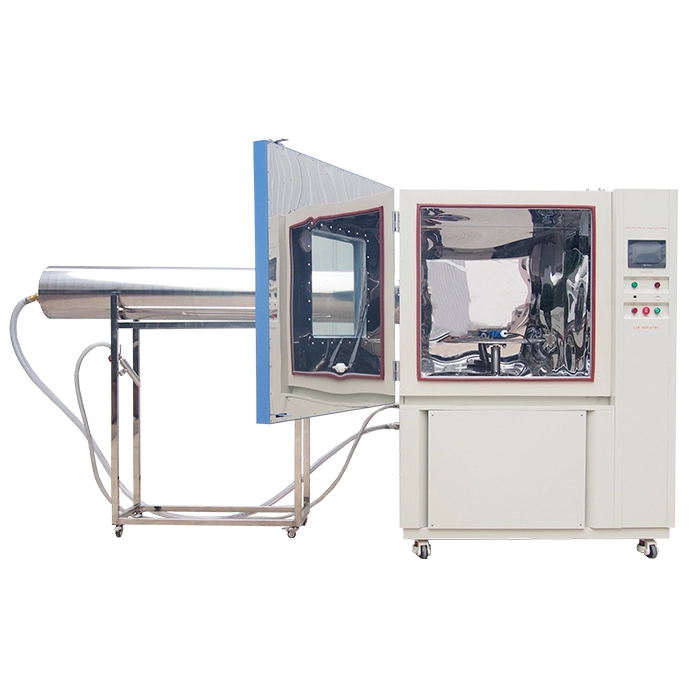

In the vast field of modern technology and industrial production, product quality and reliability have always been the focus of attention. Environmental testing as a key link to ensure product quality.No matter what kind of environment, complex, simple, can not leave temperature and humidity.This is why the environmental factors provided by the temperature and humidity test chamber are very simple and basic but very important

I. The Temperature and Humidity Test Chamber Working Principle

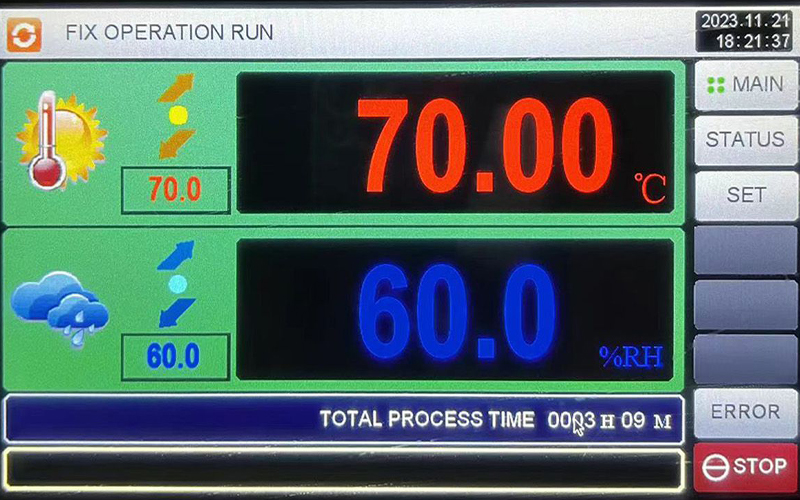

The reason why the temperature and humidity test chamber can accurately simulate various temperature and humidity environments is inseparable from its working principle. In terms of temperature control, constant temperature and humidity test chamber is equipped with advanced heating and cooling systems.

The heating system uses efficient heating wires or heating tubes. When the temperature in the test chamber needs to be raised, the current passes through the heating element, and the electric energy is quickly converted into heat energy, so that the air temperature in the chamber rises.

The refrigeration system uses the principle of compressor refrigeration, through the circulation of refrigerant, the heat in the thermal humidity chamber is taken away, and the cooling effect is achieved. Under the coordination of the precision temperature sensor and the intelligent control system, the temperature can be accurately controlled within a very small error range.

Common humidification methods include steam humidification and water mist humidification. Steam humidification by heating water to boil to produce steam, and then inject steam into the test chamber to increase humidity; LIB temperature and humidity test chamber adopts steam humidification.

II. Wide Temperature and Humidity Range to Simulate Various Environmental Conditions

In the simulation of high temperature environment, such as the aerospace field, aircraft engine parts need to run statically in a high temperature environment for a long time, and the high temperature environment simulated by the temperature and humidity test chamber can detect the heat resistance of its materials, the stability of the structure and the high temperature resistance of the coating, etc., to ensure that there will be no failure due to high temperature in actual flight. For chips in the electronics industry, high temperature testing can check whether their performance will drift or fail under long-term high temperature work, which provides a key basis for the heat dissipation design of electronic products.

Simulations of low-temperature environments are also indispensable. In polar research equipment, the low temperature environment will have a great impact on the toughness of materials and the sensitivity of electronic components. The low temperature environment created by the temperature and humidity test chamber can find out in advance whether the material will become brittle and break at low temperatures, and whether the electronic circuit will have abnormal signal transmission due to low temperatures. For example, the starting performance and driving stability of cars in cold areas also need to optimize the working state of the engine, brake system and electronic control system in low temperature environment through low temperature environment simulation test.

The simulation of high humidity environment is of great significance to the detection of moisture resistance and insulation of products. In the field of Marine engineering equipment, long-term exposure to high humidity in the Marine environment, metal components are easy to rust corrosion, insulation performance of electronic equipment may decrease, resulting in short circuit fault. The high humidity environment simulated by the temperature and humidity test chamber allows the product to be exposed to these problems in advance, so that the developer can take effective protective measures, such as the use of special moisture-resistant coatings, sealing design or optimized insulation materials.

Low humidity environment simulation is mainly for some products that are electrostatic sensitive or have special requirements in dry environments. For example, in an electronic chip manufacturing workshop, a low humidity environment may cause electrostatic discharge, causing irreversible damage to the chip. By simulating the low humidity environment in the temperature and humidity test chamber, the antistatic ability of the product can be tested, and the enterprise can formulate corresponding electrostatic protection solutions, such as installing electrostatic elimination equipment and using anti-static packaging.

The temperature and humidity changes in nature are complex and unpredictable, such as outdoor communication base station equipment, which needs to withstand the change of four seasons, the temperature difference between day and night, and the temperature and humidity changes under different weather conditions. By simulating this cyclic change, the temperature and humidity test chamber can detect the structural integrity of the product in the process of repeated expansion and contraction, the durability of the material and the reliability of the electronic components, and ensure that the product always maintains stable performance in the process of long-term use.

III. The Role of Product Development and Quality Control

In the process of product development and quality control, the damp heat chamber has always been the right-hand man of the enterprise, silently promoting the continuous optimization and upgrading of the product.

Temperature and humidity test chamber is of great significance in product development, production and market competition. During research and development, thermal humidity chamber can simulate a variety of environments to test the properties of polymer materials and help determine the material formula and process. In production, it can spot check products, such as testing the moisture resistance of food packaging to control quality. In terms of market competition, medical devices that have been rigorously tested by it are more reliable and can enhance their competitiveness.

Widely used in the industry, the electronics industry, can simulate extreme environment test mobile phone screen, battery, etc. In the automotive industry, it can test the performance of parts and vehicles in different climatic environments; The pharmaceutical industry has strict requirements for temperature and humidity testing, which can simulate the environment of drug storage, transportation and other links, test the stability of drug packaging and active ingredients, and also test the reliability of household medical devices.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español