Features and Benefits of IEC 60529 Dust Chamber

1. Precisely control the dust concentration,between 2 and 4kg/m³, to meet the requirements of different test standards. Airflow speed control ensures that dust can effectively adhere to the surface of the test piece without causing impact and damage.

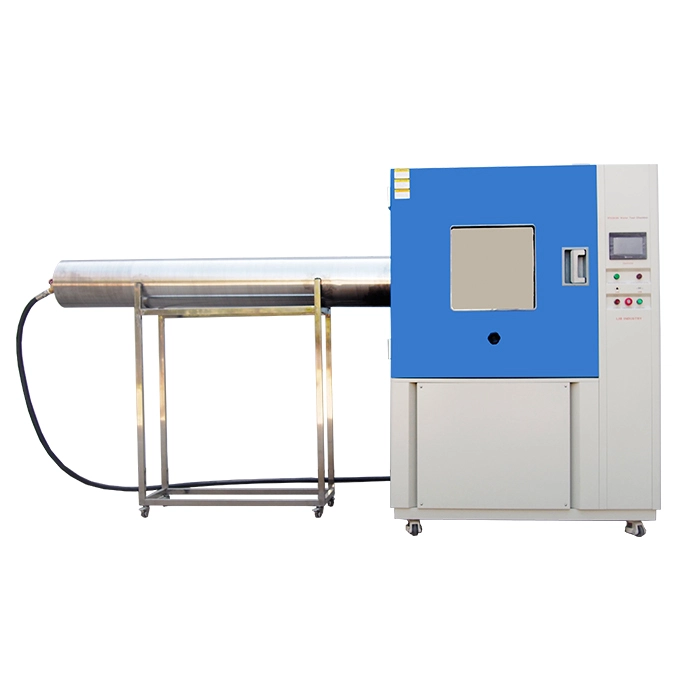

2. The workroom has a convex design and sealing rubber strip to prevent sand and dust leakage. At the same time, it is equipped with an electromagnetic lock, so that the workroom door cannot be opened during the test to prevent misoperation.

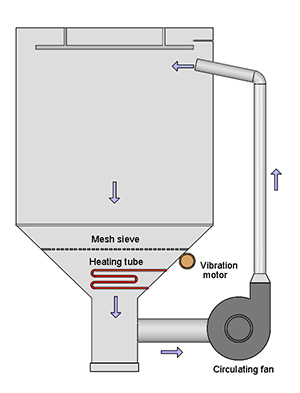

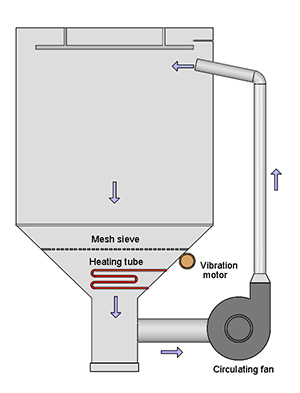

3. The dust pumped up is sent to the top of the inner chamber, and then vertically down from the top naturally, and the dust can be recycled.

4. Different test modes can be selected according to different test requirements, such as continuous dust blowing, intermittent dust blowing, timed dust blowing, etc.

Specifications of IEC 60529 Dust Chamber

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

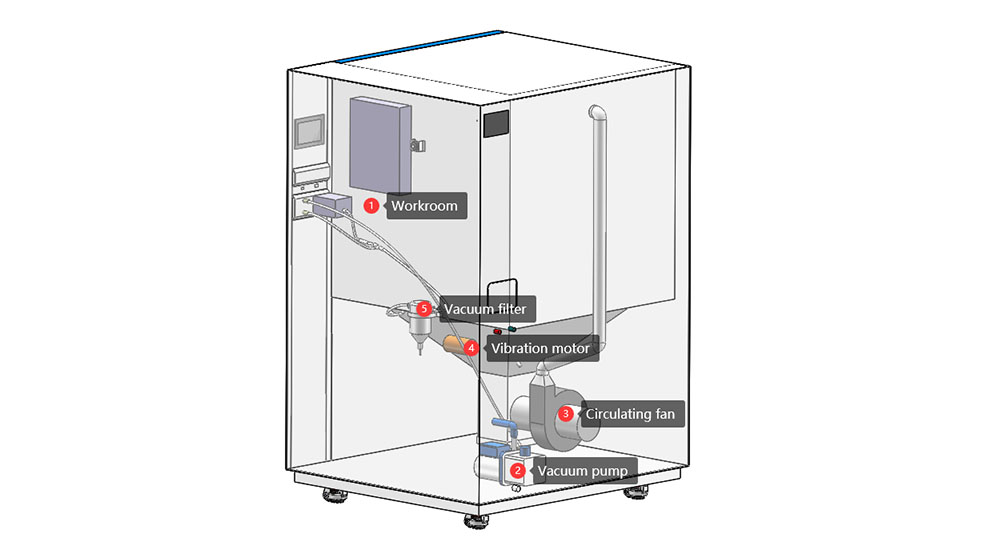

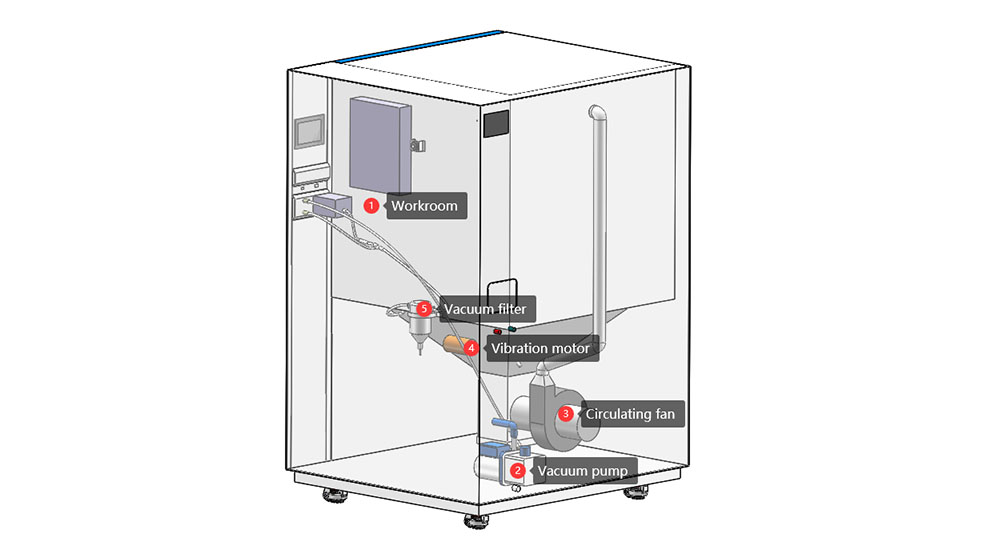

Configuration of IEC 60529 Dust Chamber

| ①Workroom | SUS304 stainless steel inner wall, corrosion resistance, high temperature resistance, mirror material, not easy to stick to dust. A conical funnel is located at the bottom of the workroom to collect dust.

|  |

| ②Vacuum pump | Quickly remove the air from the test chamber and maintain a stable vacuum degree. |  |

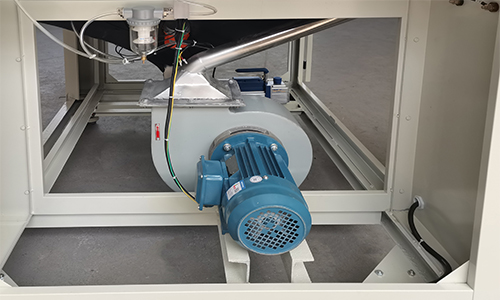

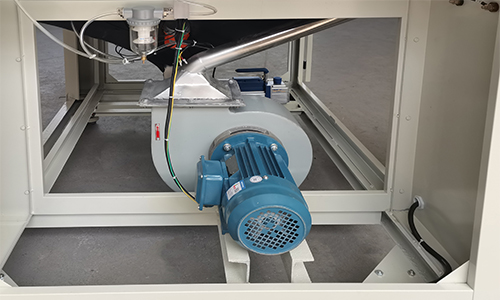

| ③Circulating fan | Circulate the sand and dust in the test chamber. The inlet and outlet of the fan are directly connected with the air duct, and the diffusion port on the top of the workroom is connected to the working room to form an "O" type closed vertical dust blowing circulation system.

|

|

| ④Vibration motor | Shake off excess dust stuck to the interior of the workroom and the cone of the funnel. |  |

| ⑤Vacuum filter | Filter out dust particles and other impurities in the gas in the dust test chamber to ensure the normal operation of the vacuum system. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español