In scientific research, quality testing, and various industrial applications, maintaining precise environmental conditions is often crucial. Benchtop Environmental Chambers are specially designed tools that excel in achieving and maintaining precise climate control. In this article, we delve into the science behind these chambers, exploring the intricate mechanisms that enable precision climate control in controlled environments.

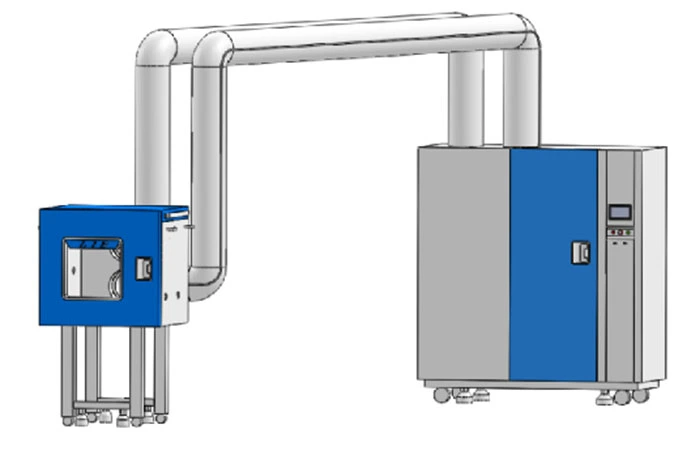

Before we dive into the science, let's understand the fundamentals of benchtop environmental chambers. These chambers are compact, self-contained units used to create and maintain controlled environments, typically for testing or research purposes. They are capable of controlling parameters such as temperature, humidity, and sometimes even pressure and light.

Benchtop environmental chambers are used across a wide range of industries, including electronics, pharmaceuticals, biotechnology, materials science, and more. Their applications span from testing product durability under extreme conditions to simulating specific environmental conditions for research purposes.

At the core of benchtop environmental chambers is precise temperature control. This control is achieved through a combination of heating and cooling elements, along with sophisticated temperature sensors. By regulating the power supplied to these elements, the chamber can achieve and maintain a stable temperature within tight tolerances.

Thermal Insulation: The chamber's walls are often insulated to minimize heat exchange with the surrounding environment, ensuring accurate temperature control.

Thermoelectric Elements: Some chambers use Peltier devices (thermoelectric elements) to provide precise temperature control without the need for refrigerants or compressors.

For applications that require humidity control, benchtop environmental chambers employ several techniques to regulate moisture levels. Humidity control is essential for tests related to product reliability, material properties, and biological research.

Humidification Systems: These systems introduce moisture into the chamber using various methods, such as steam generation or ultrasonic humidifiers.

Dehumidification Systems: Dehumidifiers remove excess moisture from the chamber when necessary to maintain desired humidity levels.

To ensure uniform conditions throughout the chamber, airflow control is critical. Fans or blowers distribute air evenly, preventing temperature and humidity gradients.

Convection: Natural convection or forced convection systems are used to circulate air, depending on the design of the chamber.

The heart of benchtop environmental chambers is the control system. These systems utilize advanced sensors and feedback mechanisms to continuously monitor and adjust environmental conditions. They offer precise digital control over temperature, humidity, and other parameters.

PID Control: Proportional-Integral-Derivative (PID) control algorithms are commonly used to fine-tune conditions based on real-time feedback from sensors.

Benchtop environmental chambers are equipped with safety features to prevent overheating, excessive humidity, or other potentially hazardous conditions. These mechanisms ensure the safety of both the equipment and the specimens being tested.

Benchtop environmental chambers are remarkable tools that rely on a combination of advanced engineering and scientific principles to provide precision climate control. Whether used for research, testing, or quality assurance, these chambers enable researchers and professionals to replicate specific environmental conditions with an unmatched level of accuracy. By understanding the science behind these chambers, we can appreciate their vital role in advancing various fields of science and industry, from electronics development to pharmaceutical research.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español