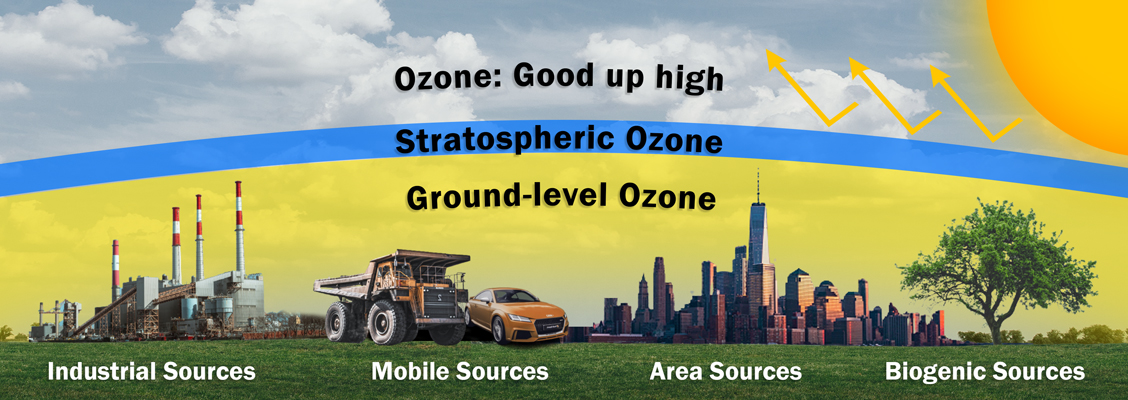

Ozone (O3) is a strong oxidizing agent that is widely present in the atmosphere, especially in urban industrial areas and at high altitudes.

The enhancement of ultraviolet irradiation caused by the destruction of the ozone layer will also accelerate the aging and destruction of materials such as construction, spraying, packaging, cables, and polymers, thus causing serious harm to human production and life. The ozone test chamber can artificially control the ozone concentration, temperature and humidity, and evaluate the durability of materials under the action of ozone, so as to predict its life and reliability in actual use.

There are several common methods for generating ozone in ozone test chambers. Including ultraviolet irradiation, electrolysis, and silent discharge.

The ozone test chamber not only needs to precisely control the concentration of ozone, but also needs to precisely adjust the temperature, humidity and other environmental parameters. At the same time, the test chamber is equipped with a high-precision ozone concentration sensor to monitor the change of ozone concentration in real time, and adjust the ozone generation through the feedback control system to ensure that the ozone concentration in the chamber is always maintained at a preset level.

In the rubber and plastic products industry, ozone is one of the main factors leading to product aging failure.Rubber tires will be eroded by ozone in the atmosphere during long-term use, resulting in cracks on the surface of the tire, which seriously affects the service life and safety of the tire. The ozone test chamber can accelerate the aging test of rubber tires, seals, plastic pipes and other products. In the test process, the sample is placed in the test chamber, set a specific ozone concentration, temperature and humidity conditions, after a certain period of exposure, observe the changes in the surface of the sample, such as the degree of cracking, color changes, etc.

Through the comparative test of samples produced by different formulations and processes, the materials and formulations with excellent anti-ozone aging properties can be selected, which provides a basis for the optimization of products. For example, adding additives such as anti-ozone agents to rubber formulas can effectively improve the anti-ozone aging ability of rubber products. Through the test of ozone test chamber, the best addition amount and use effect of anti-ozone agent can be determined, so as to guide the production practice.

In addition to aging testing, ozone test chambers are also widely used in the performance evaluation of rubber and plastic products. For some ozone-sensitive products, such as rubber seals, the anti-ozone cracking performance is directly related to the sealing effect and service life of the product. By simulating different ozone environments in the test chamber, the mechanical properties of the seals are tested by tensile and compression, and the cracking of the seals under the action of ozone can be accurately evaluated.

For plastic products, the ozone test chamber can be used to evaluate the mechanical properties of its resistance to ozone aging, such as the degree of decline in strength, toughness and other indicators. In the production process of plastic pipes, the performance evaluation of ozone test chamber can determine the service life of pipeline materials under different ozone concentrations, provide a reference for the design and installation of pipelines, and avoid pipeline leakage and other problems caused by material aging.

Many materials in electronic and electrical equipment, such as insulation materials, cable jackets, etc., may deteriorate in the ozone environment, affecting the electrical performance and safety of the equipment. The ozone test chamber can be used to test the ozone resistance of these materials. During the testing process, the sample of insulation material or cable sheath is placed in the test chamber, and the ozone concentration, temperature and humidity conditions that meet the requirements of the actual use environment or relevant standards are set. After a certain period of exposure, the electrical performance indicators such as insulation resistance and breakdown voltage of the sample are tested, and the changes of the material surface are observed. Such as whether there is cracking, discoloration and other phenomena.

Electrical and electronic products may operate at different ozone concentrations throughout their life cycle, such as in areas with severe industrial pollution or near high-voltage electrical equipment. The ozone test chamber can be used to simulate these special environments and verify the reliability of electronic and electrical products. By placing the complete product in the test chamber, the ozone exposure test is carried out according to the predetermined test procedure, and the various functions of the product are monitored in real time, such as the switching performance of electrical appliances and the accuracy of signal transmission.

At the end of the test, the product is comprehensively evaluated, including electrical performance, mechanical performance, appearance and other aspects of the inspection. Based on the test results, problems in product design, material selection or manufacturing process can be found and timely improvements can be made.

In the textile industry, ozone test chamber can be used to test the ozone fading resistance of textiles. Many color textiles are prone to fading under the action of ozone, which affects their appearance and quality. By placing textile samples in the test chamber, simulating different ozone environmental conditions and observing the change of textile color, the anti-ozone fading ability can be evaluated, and the reference can be provided for the selection of dyes and the improvement of dyeing process.

In the coating industry, the ozone test chamber can be used to test the ozone resistance of coatings. Coatings in the outdoor environment will be exposed to ozone for a long time, easy to appear powder, peeling and other phenomena. Through the ozone exposure test of the paint sample in the test chamber, the change of the gloss, adhesion, hardness and other performance indexes of the paint can be selected with good ozone corrosion resistance, and the durability and protection effect of the paint can be improved.

In the aerospace industry, the ozone test chamber can be used for rigorous ozone tolerance testing of aerospace materials and components due to the high ozone concentration of aerospace spacecraft flying at high altitudes.