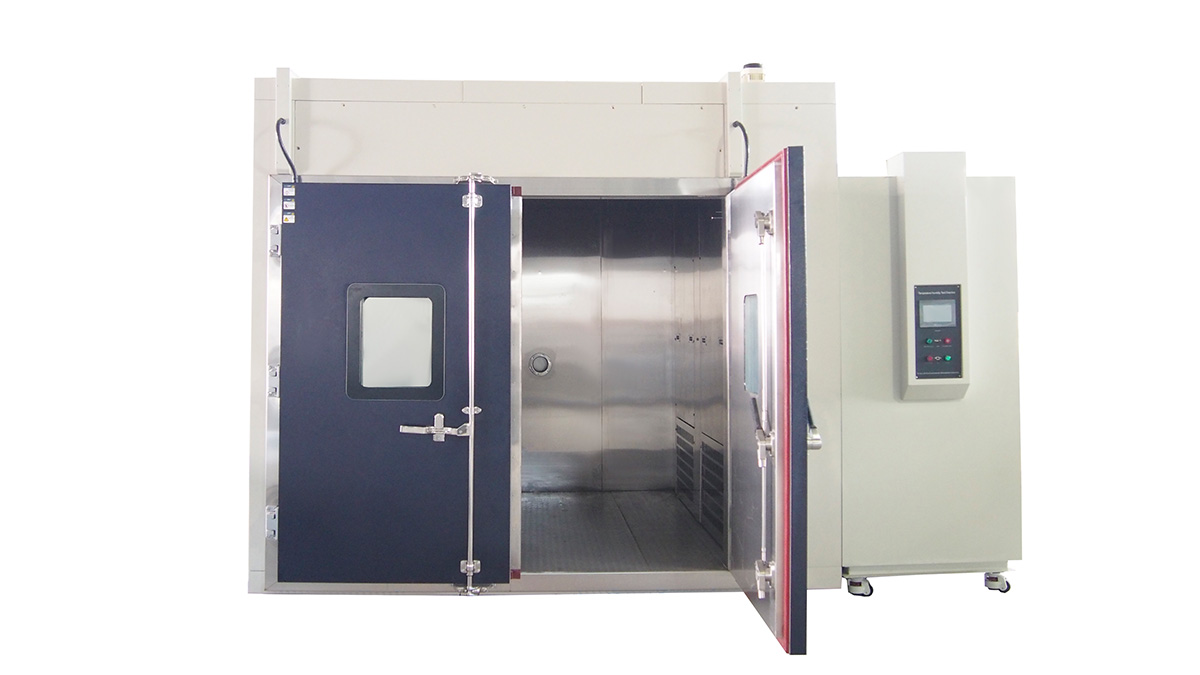

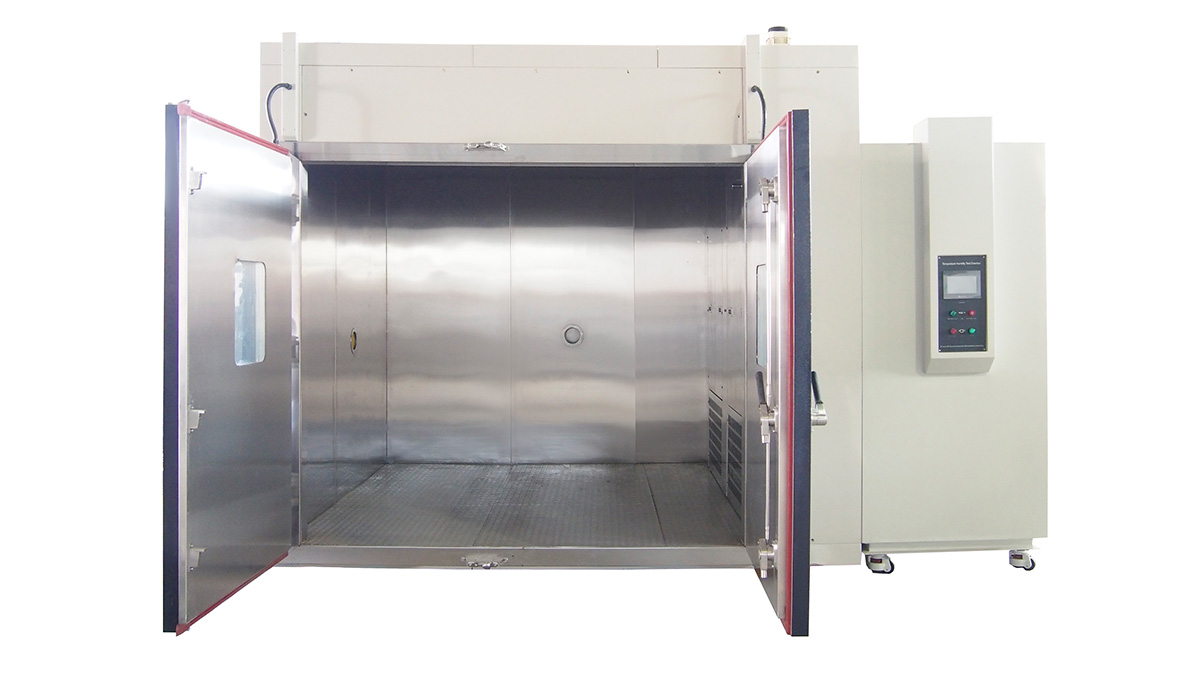

A walk in test chamber, also known as a walk in testing chamber or walk in environmental test chamber, is a large-scale environmental testing device that allows testers or larger test samples to directly enter the chamber for environmental simulation testing. Its working principle mainly involves the following aspects:

Temperature Control: The temperature inside the chamber is regulated by a built-in refrigeration system and heating system. The refrigeration system typically includes a compressor, condenser, expansion valve, and evaporator, while the heating system generally uses electric heaters.

Humidity Control: The relative humidity inside the chamber is controlled by a humidifier and a dehumidifier. The humidifier adds water vapor to the air, while the dehumidifier removes excess moisture by cooling the air to its dew point temperature.

The chamber is equipped with multiple fans to circulate air, ensuring even distribution of temperature and humidity. Fans draw air from one end of the chamber, process it through heating or cooling, and then blow it back into the chamber.

The chamber is equipped with a microprocessor or PLC (Programmable Logic Controller) control system to set and adjust test parameters (such as temperature, humidity, and time) and monitor the testing process. The control system can also record and store test data for analysis and traceability.

The chamber is fitted with various safety protection devices, such as over-temperature protection, over-humidity protection, and emergency stop buttons, to prevent equipment overload and ensure the safety of the operators.

1. Set Test Parameters: Use the control system to set the desired temperature, humidity, and test duration.

2. Heating or Cooling:

1. If heating is required, the control system activates the heater. The air is heated and then circulated into the chamber by fans.

2. If cooling is required, the control system activates the refrigeration system. The air is cooled and then circulated into the chamber.

3. Humidity Adjustment: Based on the set humidity value, the control system adjusts the operation of the humidifier or dehumidifier to achieve the required relative humidity.

4. Air Circulation: Fans operate continuously to ensure even distribution of temperature and humidity within the chamber.

5. Data Recording: The control system records temperature and humidity data throughout the testing process.

6. Safety Monitoring: The safety protection system continuously monitors the operating status of the chamber to ensure the testing process is safe and reliable.

7. Test Completion: Once the set test time is reached, the control system shuts down the heating, cooling, and humidity adjustment equipment, ending the test.

Walk-in test chambers are widely used in industries such as aerospace, automotive, electronics, chemical, and pharmaceuticals for environmental adaptability tests, including high and low-temperature tests, humidity tests, and temperature-humidity cycling tests.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español