Temperature Altitude Chamber Features and Benefits

1. Accurately simulate the air pressure environment from sea level to thousands of meters high, the range of air pressure changes can be adjusted arbitrarily, and can be combined with high and low temperatures and other conditions.

2. The control system is highly automated, and can accurately adjust and control temperature, pressure and other parameters according to the preset program.

3. The product is tested under extreme low pressure conditions, and the ability and reliability of its work in high altitude, high altitude and other environments are accurately evaluated.

4. Widely used in aerospace, electronics, automotive and other fields to meet the strict standards and regulatory requirements of product environment adaptability in various industries.

Low Pressure Test Procedure in Temperature Altitude Chamber

1. Preparation before test :

Determine test samples and test standards.

Calibrate and prepare test equipment.

Record the initial status and parameters.

2. Low Pressure storage test :

Place the device in a low pressure environment to simulate high altitude storage conditions.

Maintain the specified time to observe the mechanical and physical changes of the equipment.

3. Low pressure working test :

Start the equipment under low pressure conditions to test its performance.

Record the working status and data of the equipment in low pressure environment.

4. Rapid decompression test :

Simulate the rapid entry of equipment from a pressurized environment into a low pressure environment to test the emergency response of the equipment.

Hold the specified time to observe the transient response and damage of the equipment.

5. Explosion decompression test :

Simulates extremely rapid pressure drops, similar to decompression conditions after an explosion.

Perform pressure changes over a short period of time to observe structural damage and functional failure of the equipment.

Temperature Altitude Chamber Specifications

Model | A1000 |

Internal Dimension | Depth 1500 width 1000 height 970mm |

Overall Dimension | Depth 2050 width 1300 height 2200mm |

Interior Volume | 1000L |

Temperature Range | -20℃ ~ +150 ℃ -40℃ ~ +150 ℃ -60℃ ~ +150 ℃ -120℃ ~ +150 ℃ |

Temperature Fluctuation | ≤ ±0.5℃ |

Temperature Deviation | ≤ 2.0℃ |

Temperature Uniformity | ≤ 2.0℃ |

Humidity Range | 20%RH ~ 95%RH (can be controlled above 50Kpa) |

Cooling Rate | 2 ℃ / min |

Heating Rate | 3 ℃ / min |

Pressure Range | Atmospheric pressure to 0.5kPa standard atmospheric pressure 101.kpa |

Pressure Deviation | ±2Kpa |

Pressure Reduction Time | Atmospheric pressure to 0.5kpa ≤30min |

Pressure Housing | manganese steel, surface spray treatment |

Other outer wall materials | doublesided galvanized steel plate, surface spray treatment |

Vacuum system | vacuum pump, exhaust regulating valve, charging regulating valve |

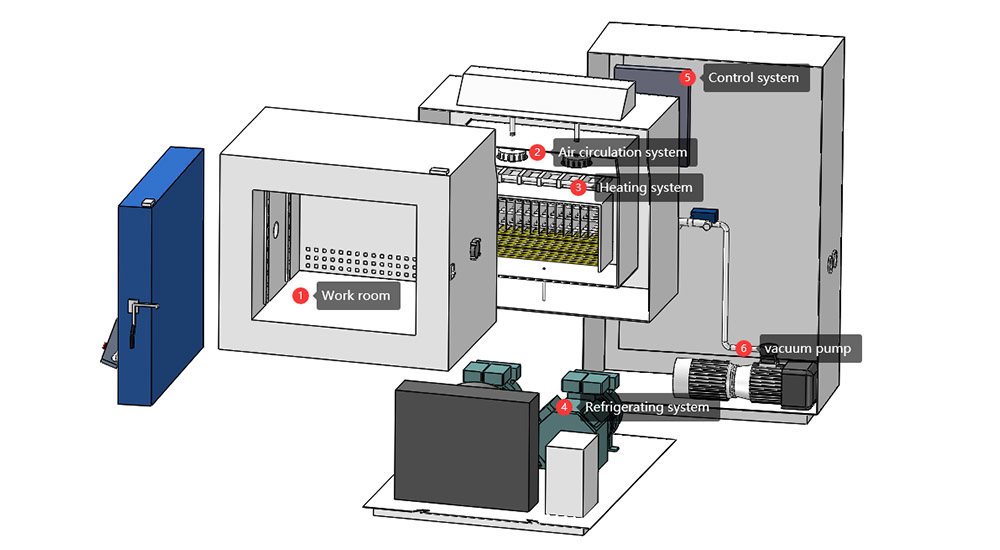

Configuration of Temperature Altitude Chamber

① Workroom |

Workroom is made of 304 stainless steel plate Double punched sample holder, standard bearing capacity 50kg, equipped with high precision temperature probe.

|  |

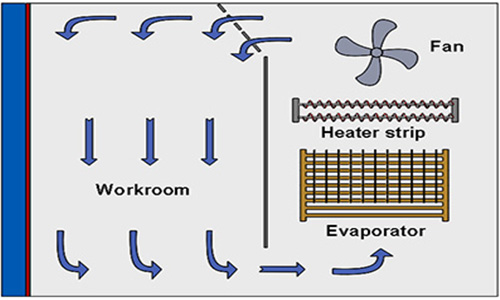

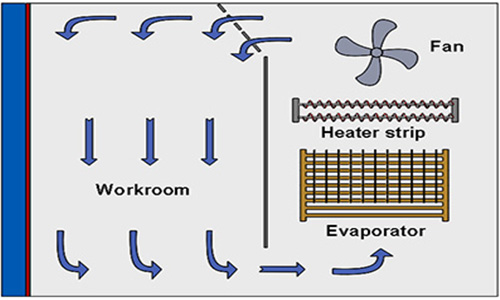

② Air circulation system

| Composed of fans, air ducts, regulating valves, etc., it can ensure the circulation and discharge of air in the test room, and make the temperature, humidity, pressure and other parameters in the chamber more uniform and stable. |  |

③ Heating system | Composed of heating tube, hot air circulation, etc., it can increase the temperature in the chamber according to the test requirements to meet the low pressure and temperature test needs of different products. |  |

④ Refrigerating system | It is usually composed of compressor, condenser, evaporator, throttle valve, refrigerant, etc., which is used to reduce the temperature in the chamber to simulate different environmental conditions. |  |

⑤ Control system | Responsible for the control and management of the whole test process, can set the test parameters, monitor the test process, and record and process the test data, equipped with a touch screen operation interface, convenient for users to operate and view the results.

|  |

⑥ Vacuum pump | The air in the chamber is extracted to establish a low pressure environment, and the air pressure in the chamber can be accurately controlled. | .jpg) |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español

.jpg)