Salt Spray Cabinet Features and Benefits

1. Compared with the corrosion in the natural environment, the salt spray environment in the salt spray testing cabinet can accelerate the corrosion rate of the product, greatly shorten the test cycle, and improve the test efficiency.

2. The concentration of salt spray is generated and controlled stably, so that the salt spray is evenly sprayed on the surface of the sample, ensuring that the test results of different batches are comparable.

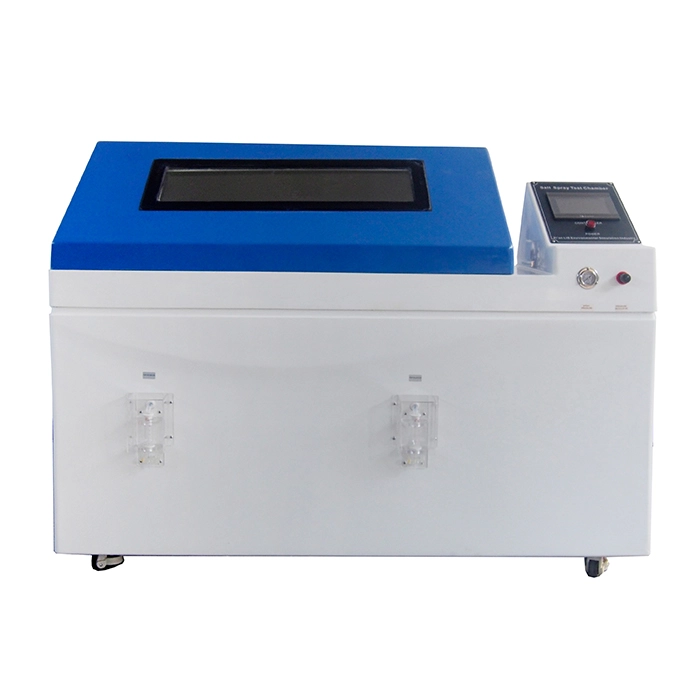

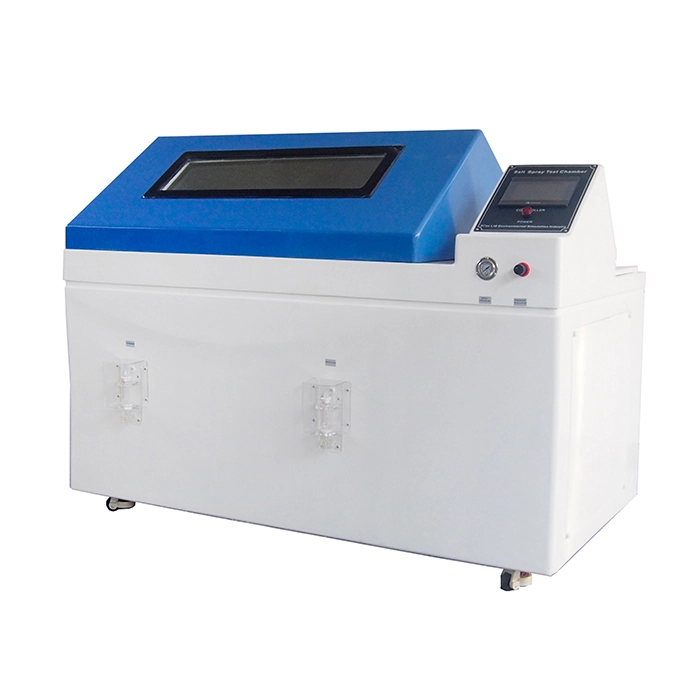

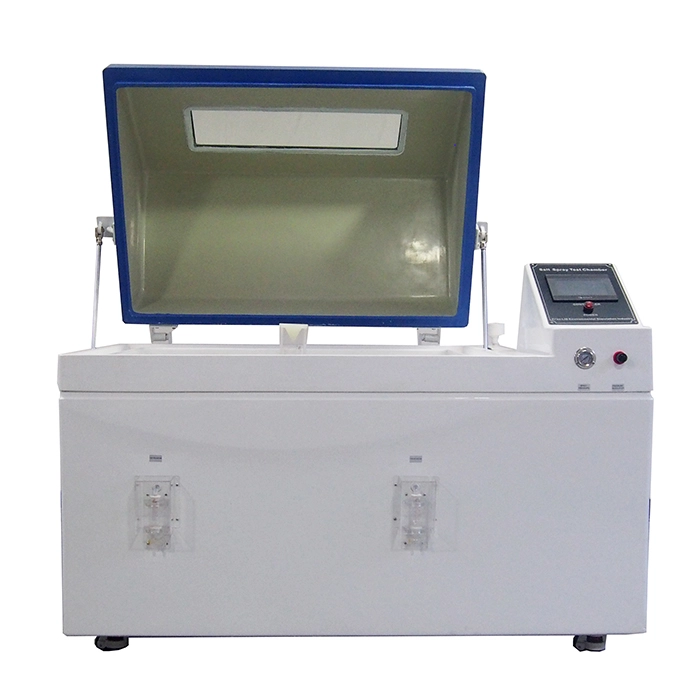

3. The closed design avoids the leakage of salt spray and the damage of salt spray to the operator.Salt spray test machine has well sealing.

4. Wide range of application, suitable for all kinds of metal and non-metal materials salt spray corrosion test, such as steel, aluminum alloy, plastic, rubber, paint and so on.

Specifications of Salt Spray Cabinet

Model | S-150 | S-250 | S-750 | S-010 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 95% ~ 98% RH |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Spray Type | Continuous / Periodic |

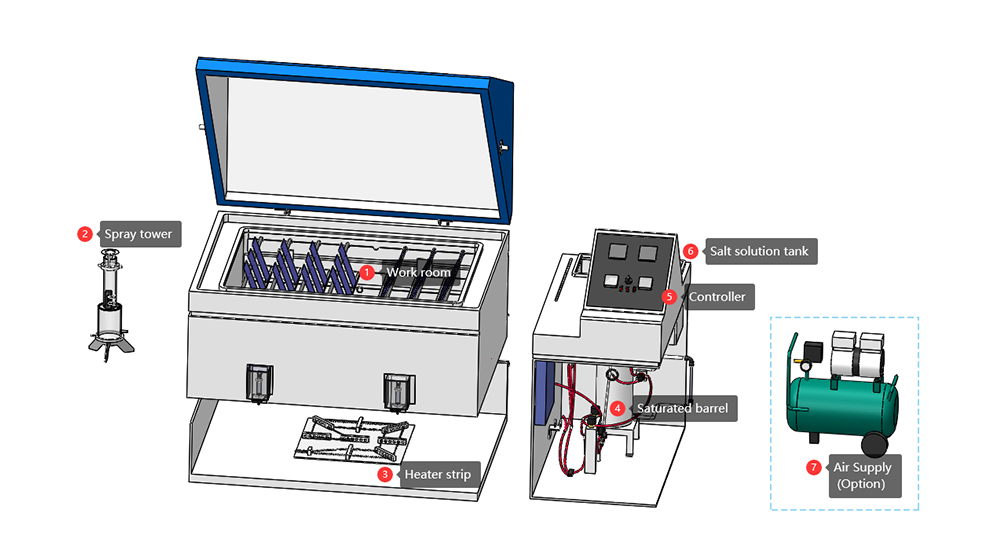

Salt Fog Collected | Fog collector and fog measure cylinder |

Air Preheating | Saturated air barrel |

Spraying System | Atomizer tower and Spray nozzles |

Controller | PID controller |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | Glass fiber reinforced plastics |

Standard Configuration | 6 round bars and 5 V-shaped grooves |

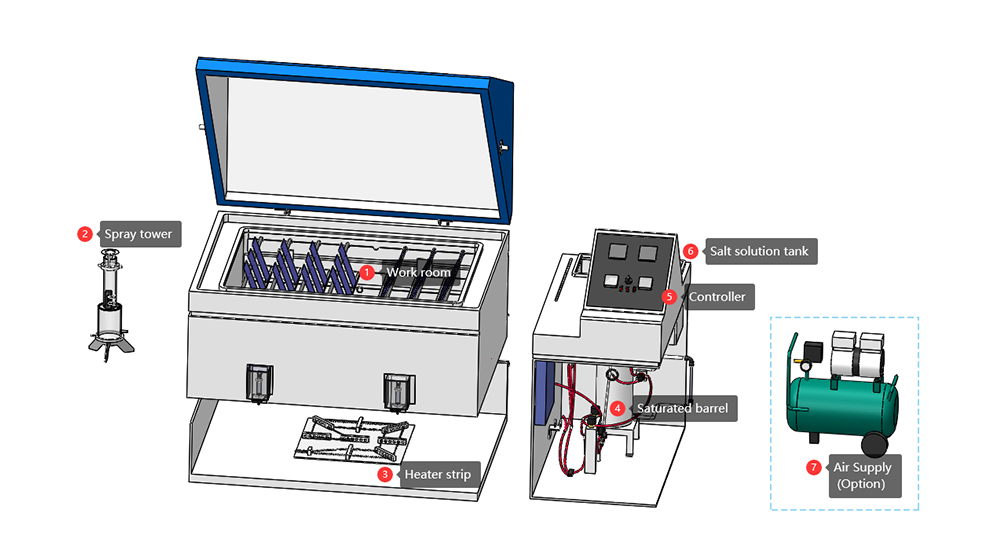

Configuration of Salt Spray Cabinet

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español