In today's rapidly advancing industrial landscape, the need for rigorous testing and quality assurance has never been more critical. One of the essential tools in this realm is the corrosive gas test chamber. These specialized environments are designed to simulate the effects of corrosive gases on various materials, components, and products, ensuring their durability and reliability in real-world applications. This article aims to explore the significance, functionality, and applications of corrosive gas test chambers in industrial settings.

A corrosive gas test chamber is a controlled environment specifically designed to expose materials to corrosive gases, such as H2S, CL2, and SO2. These chambers,such as ozone aging test machine, allow researchers and manufacturers to assess how different substances react when subjected to harsh chemical environments over time. The test chambers can replicate various temperature and humidity conditions, further enhancing the realism of the tests.

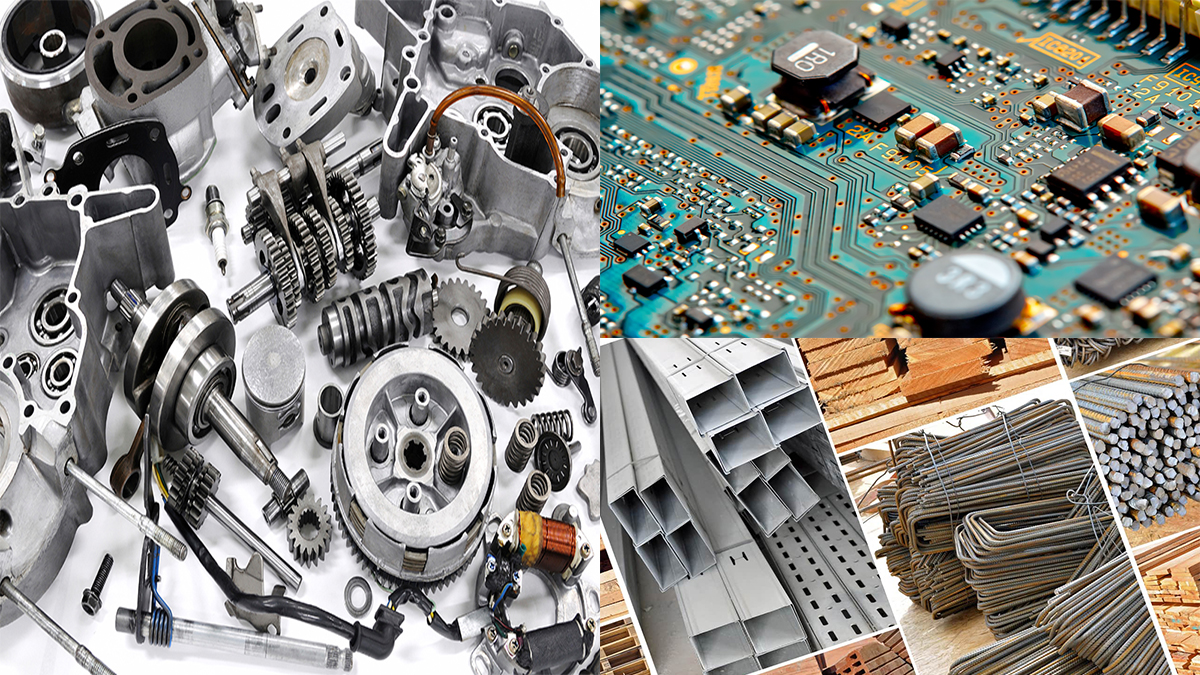

1.Material Selection: In industries such as aerospace, automotive, and electronics, selecting the right materials is crucial. Corrosive gas test chambers help engineers determine which materials can withstand exposure to corrosive environments, leading to better product longevity and performance.

2. Quality Assurance: Manufacturers can use these chambers to ensure that their products meet industry standards and regulations. By conducting thorough testing, they can identify potential weaknesses and make necessary adjustments before products reach the market.

3. Safety Compliance: Certain industries, such as oil and gas, face stringent safety regulations regarding the use of materials that may encounter corrosive gases. Testing helps ensure compliance with safety standards, reducing the risk of accidents and failures.

4. Research and Development: LIB Industry Corrosive gas test chambers play a vital role in R&D, enabling scientists and engineers to study the degradation processes of materials. This knowledge can lead to the development of more resilient materials and innovative solutions to combat corrosion.

Corrosive gas test chambers are equipped with advanced technology to create controlled environments.

Key features include:

Gas Distribution System: This system allows for precise control over the concentration of corrosive gases within the chamber, ensuring accurate testing conditions.

Temperature and Humidity Control: The ability to manipulate temperature and humidity levels is essential for simulating real-world scenarios. Most chambers come with heating and cooling systems, as well as humidity control mechanisms.

Monitoring and Data Collection: Modern test chambers are often equipped with sensors and data logging systems that track material performance. This data is crucial for analyzing corrosion rates and understanding material behavior over time.

Corrosive gas test chambers find applications in various industries:

Aerospace: Components in aircraft must withstand corrosive environments, and testing ensures their reliability during flight operations.

Automotive: Vehicles are exposed to various environmental conditions, including corrosive gases. The automotive environmental testing helps improve the longevity of automotive parts.

Oil and Gas: Equipment used in these industries is often exposed to corrosive gases. Testing ensures that materials can withstand harsh conditions, preventing failures that could lead to significant safety hazards.

Electronics: Corrosive gases can affect electronic components, leading to failures. Testing helps manufacturers develop more resilient products.

Construction: Building materials must endure exposure to various environmental factors. Testing helps in selecting materials that will last over time.

Corrosive gas test chambers are invaluable assets in the industrial sector, enabling manufacturers and researchers to ensure the durability and reliability of materials and products in corrosive environments. By understanding the significance and functionality of these test chambers, industries can enhance their quality assurance processes, comply with safety regulations, and ultimately deliver superior products to the market. As technological advancements continue, the role of corrosive gas test chambers will undoubtedly expand, further contributing to innovation and safety across various sectors.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español