Features and Benefits of Dust Test Chambers

1. Accurate simulation of The dust environment, dust particle size 50μm, The Talcum powder amount is 2kg ~ 4kg/m³, wind speed, temperature ambient to +50℃, highly restore the dust environment that the product may encounter in actual use.

2. The automation of the test process, including the blowing of dust, the start and stop of vibration, and the control of the test time, reduces the error and complexity of manual operation.

3. Large observation window with wiper, equipped with lighting, convenient for users to observe and understand the change of the product in the dust environment at any time during the test.

4. The door of the LIB Industry dust test chambers are equipped with an electromagnetic lock, and the door can be opened only when the dustproof test cabinet stops running and the safety conditions are met. Double silicone sealing strip is used to ensure that there will be no dust leakage .

Specifications of Dust Test Chambers

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

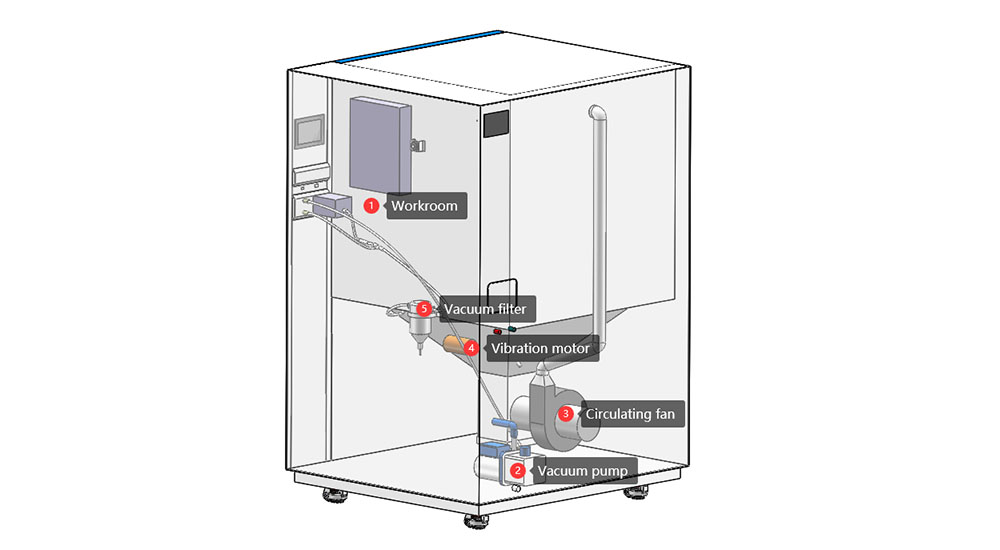

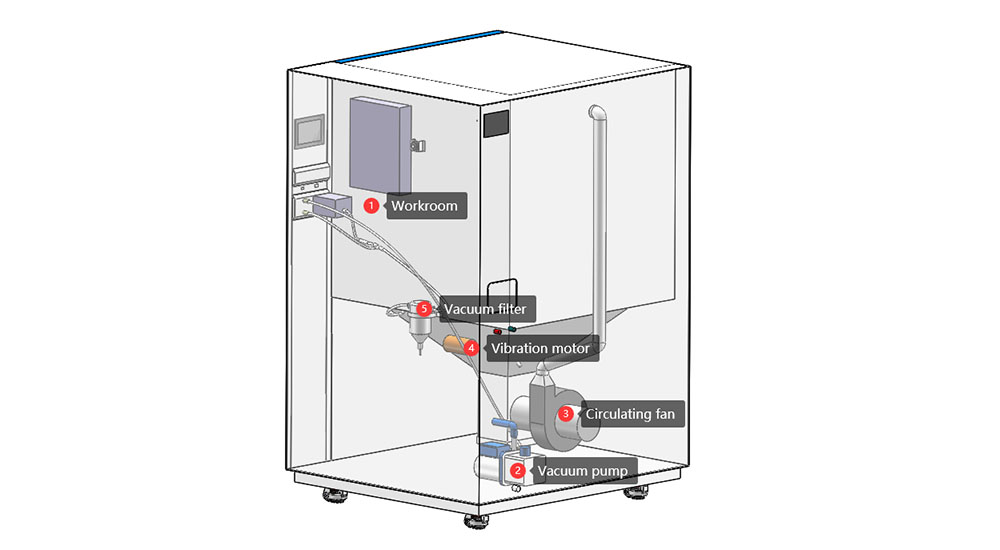

Configuration of Dust Test Chambers

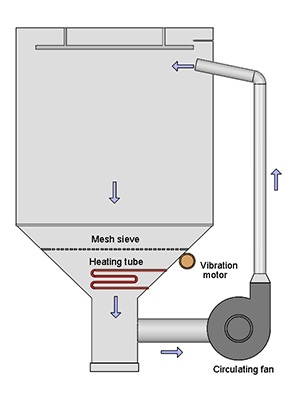

①Workroom | SUS 304 stainless steel material, can withstand the impact of sand and dust and long-term use, effectively prevent dust, dirt and other residues. Hanging sample holder and flat plate sample holder. The air duct design that produces vertical circulating air flow makes the dust disperse evenly. |

|

②Vacuum pump | Pump gas into the shell of the tested product, and adjust the pumping volume and pressure difference. |  |

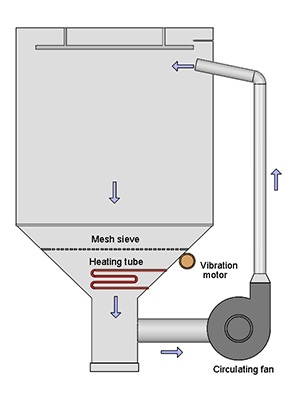

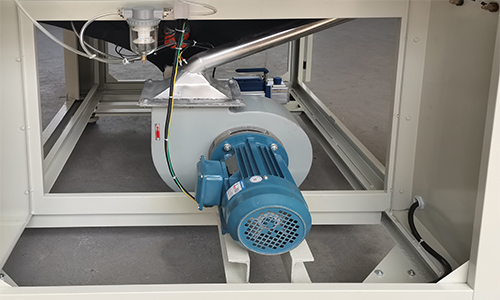

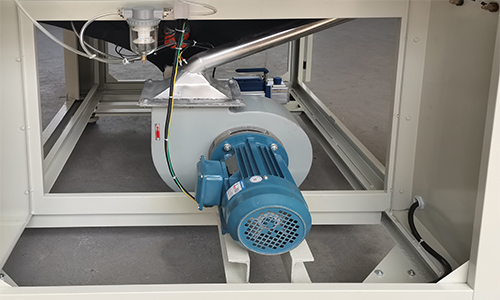

③Centrifugal fan | The main power source of sand and dust movement. The dust is sucked into the fan and sprayed into the workroom through the pipe to form a certain velocity of dust airflow to the surface of the test sample. |  |

④Vibration motor | The auxiliary dust dispersion can also shake off the dust stuck on the wall of the working room, so that the dust in the test chamber can be better dispersed and suspended |  |

⑤Vacuum filter | Filter dust and impurities to prevent them from entering the vacuum pump and causing damage to the normal operation of the vacuum pump. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español