Features and Benefits of IP6X Test Machine

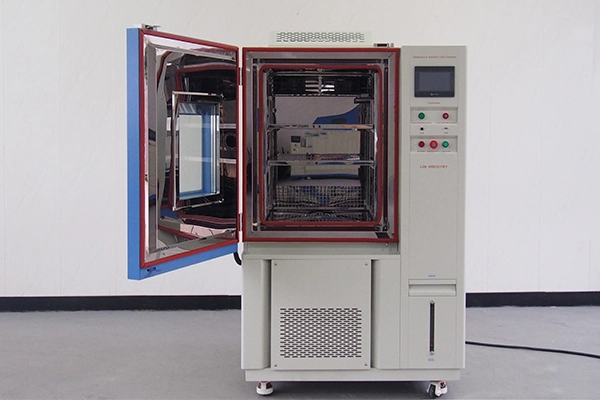

1. The "6" in IP6X means that its dust rating is the highest level, that is, it completely prevents dust from entering. Designed and tested according to IEC 60529, ISO 20653 and other international standards.

2. Extremely sealed workroom to ensure that dust does not leak into the external environment during testing. The material of the workroom is SUS304 with high strength and wear resistance, which can withstand longterm use and frequent testing.

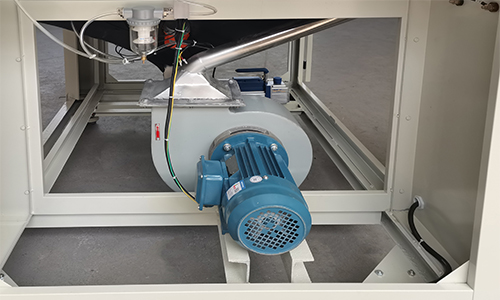

3. Equipped with a special dust circulation system for the specific concentration and particle size of dust evenly blown around the test sample. The system can control the dust blowing speed, concentration to simulate different dust environmental conditions.

4. Equipped with an electromagnetic lock, the test procedure can only be started when the workroom is completely sealed and is in a safe state, preventing dust leakage or safety accidents.

Specifications of IP6X Test Machine

Model | DI800 | DI1000 | DI1500 | DI2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dustproof socket 16A |

Controller | Programmable color LCD touch mesh sieve controller, Ethernet connection |

Safety Device | Overtemperature Protection; Overcurrent Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

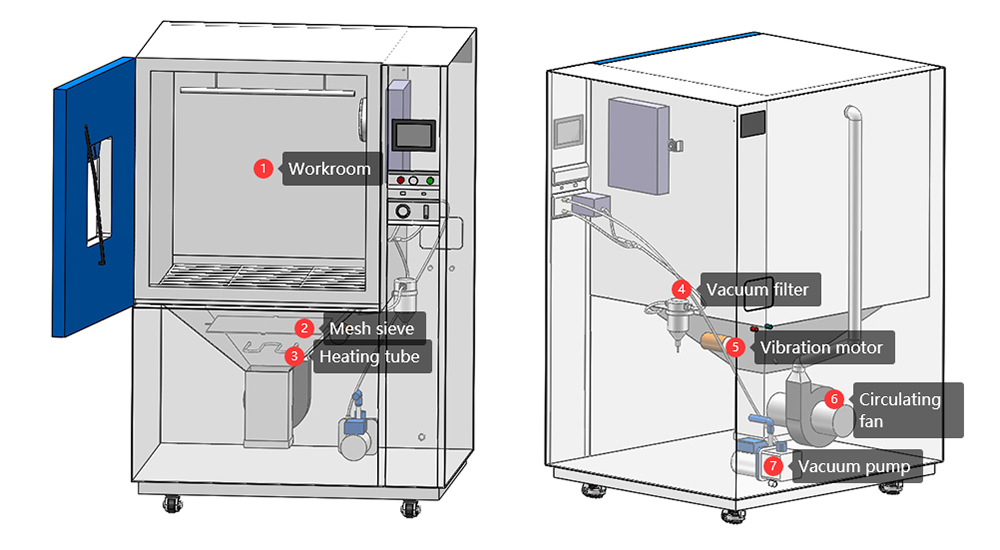

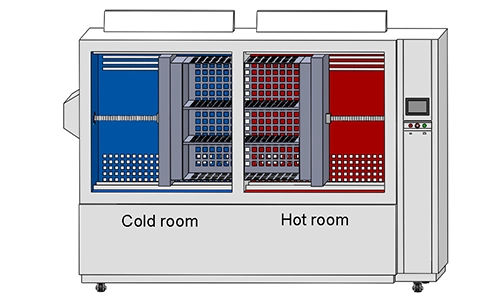

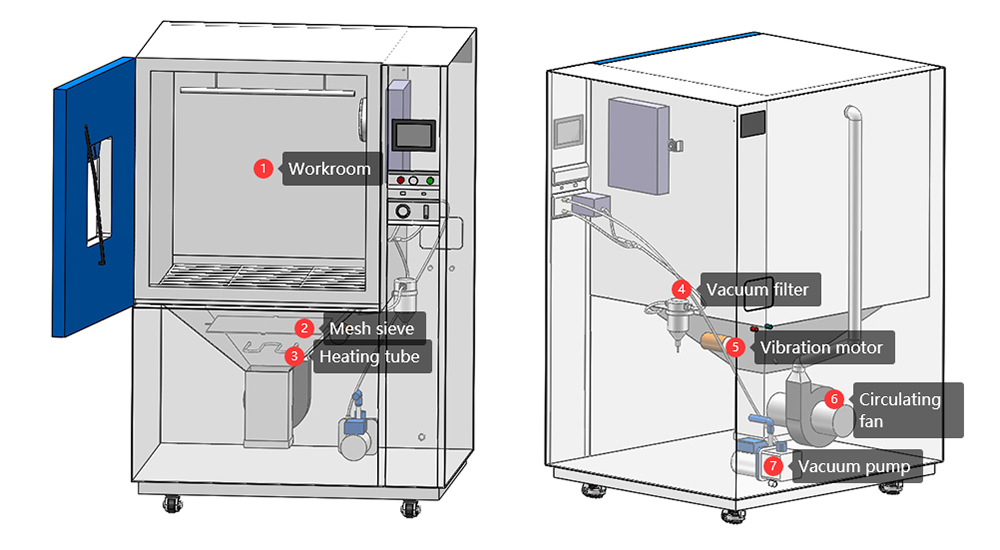

Configuration of IP6X Test Machine

...............................................................................................................................................................................................................................

Features and Benefits of IPX8 Test Machine

1. IPX8 is a higher standard in the waterproof grade, the IPX8 test machine can simulate the test environment of 1-50 meters water depth, to meet the test needs of various products with high waterproof performance requirements.

2. The housing and internal IPX8 test machine are made of 304 stainless steel, with excellent corrosion and wear resistance. Cylindrical designs can withstand greater pressure than square structures.

3. With water pressure test, air pressure test, negative pressure test and other test functions, according to the characteristics of different products and test requirements.

4. The internal test pressure can be accurately controlled to simulate the water pressure environment at different water depths. The control accuracy is high, which can reach ±0.002MPa.

Specifications of IPX8 Test Machine

Model | R78-600 |

Internal Dimension (mm) | Diameter 600mm * Height 1500 mm |

Overall Dimension (mm) | Diameter 800mm * Height 1800 mm |

Pressure | 50m water depth pressure |

Open mode | Pneumatic lid |

Material | A3 steel plate, wall thickness 15mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Storage water tank, Automatic water supply |

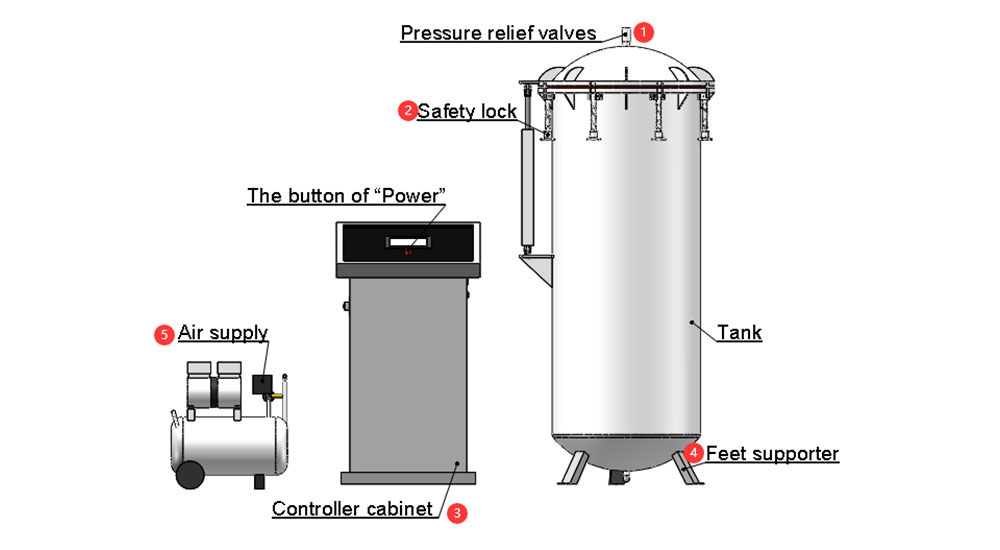

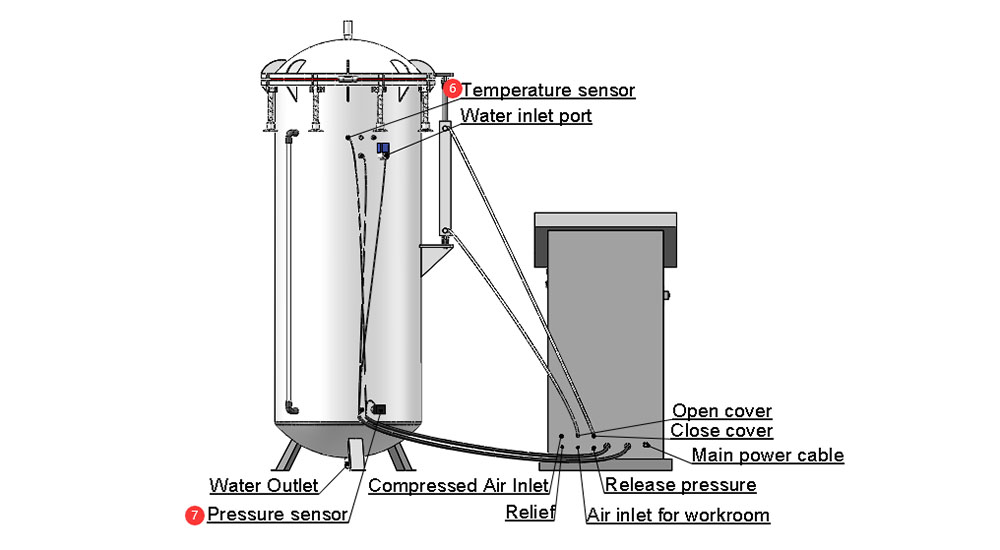

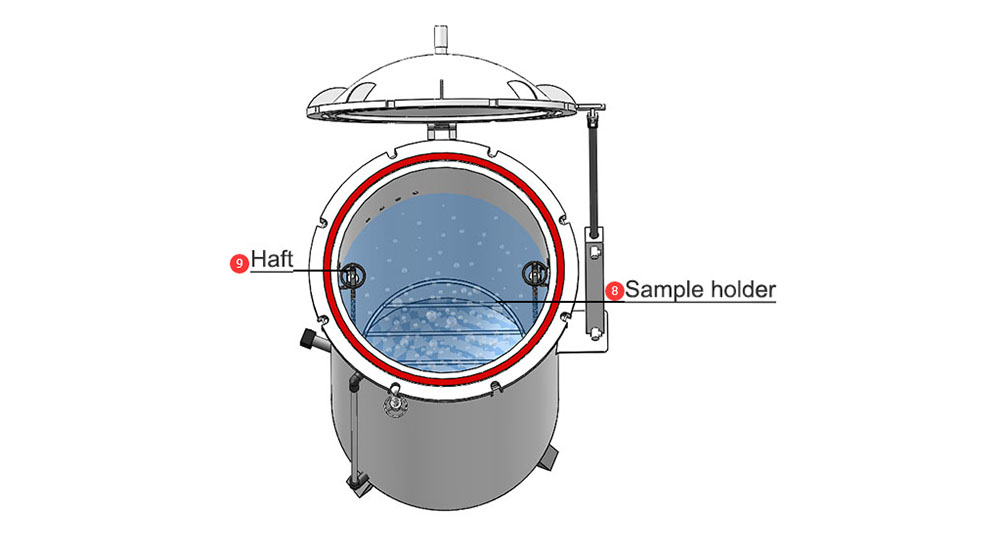

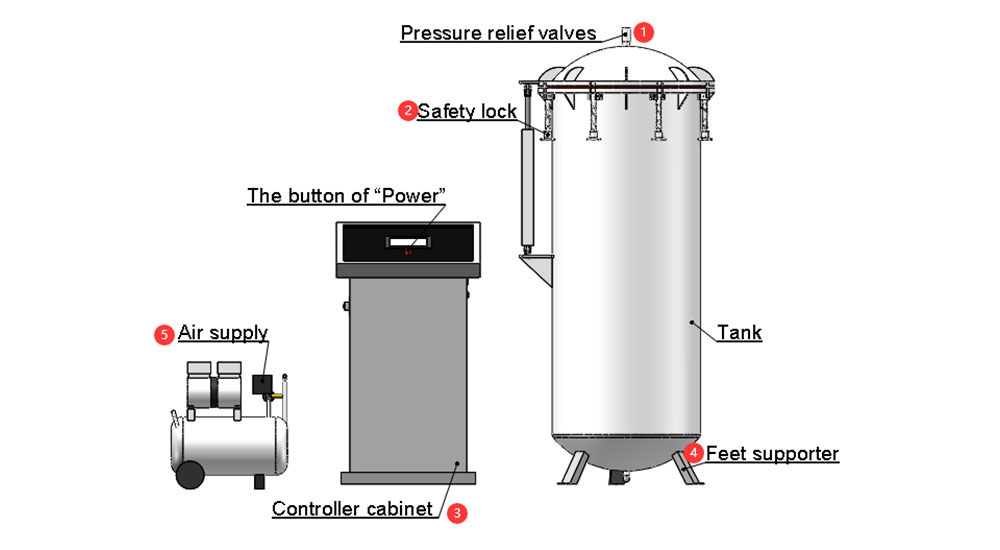

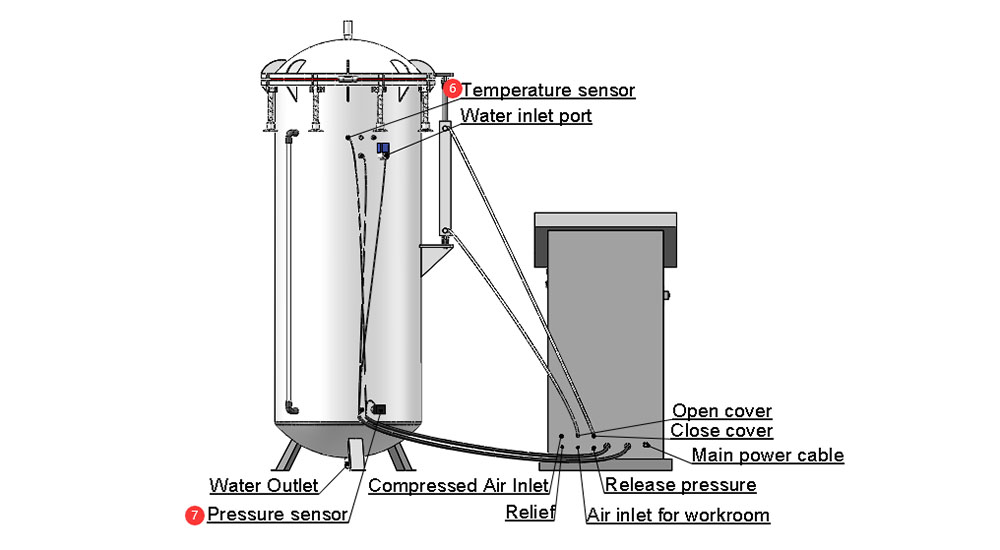

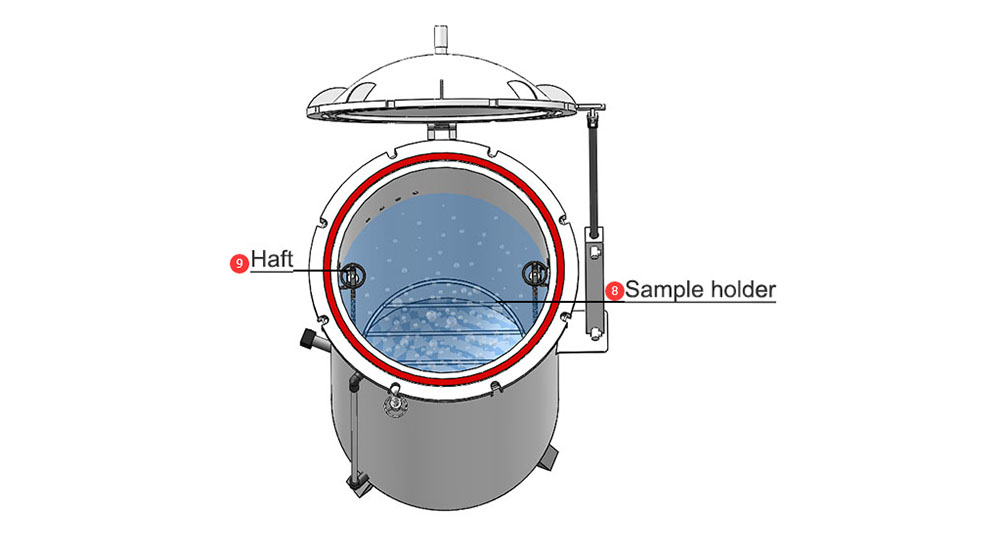

Configuration of IPX8 Test Machine

1. Pressure relief valve | When the pressure exceeds the set safe range during the test, the pressure relief valve will automatically open to release the high pressure gas inside. |

2. Safety lock | Ensure that the cover or door of the device is kept closed during testing to prevent water or pressure leakage due to misoperation or accidental circumstances that may cause the cover or door to open. Equipped with 12 manual mechanical locks.

|

3. Controller cabinet | Control the operation and parameters of the test machine, such as pressure adjustment, test time setting,etc. |

4. Foot supporter | |

5. Air source | The gas source provides the required gas pressure for the test machine, so that the test sample can be tested under a certain air pressure environment. |

6. Temperature sensor | Used to measure the temperature inside the test machine or the test sample. |

7. Pressure sensor | Real-time monitoring of pressure changes during the test, the pressure signal is transmitted to the controller of the control cabinet. |

8. Sample holder | |

9. Haft | Sample holder can aligned on both sides of the haft. |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español