In modern reliability testing, the LIB Industry Thermal Shock Test Chamber is essential for evaluating how products withstand sudden and extreme temperature changes. Rapid heating and cooling can cause mechanical stress, material fatigue, and component failure, making temperature cycling tests critical for product durability. Industries such as electronics, automotive, aerospace, and battery manufacturing rely on thermal shock testing to ensure performance and safety under real-world conditions.

|

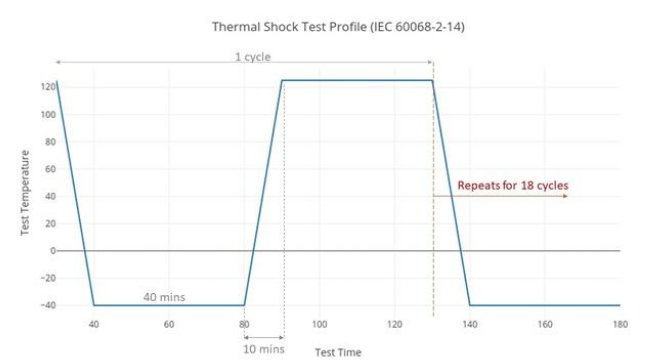

Temperature shock cycle |

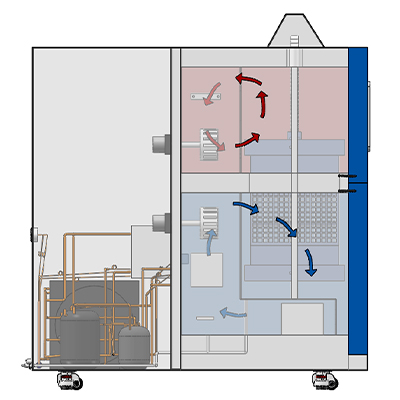

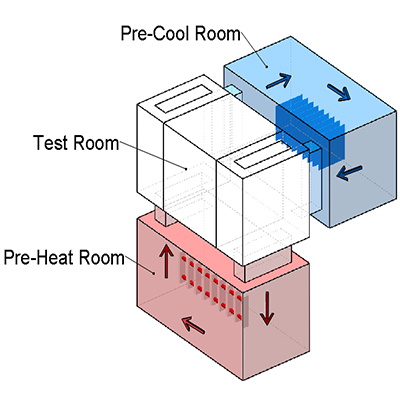

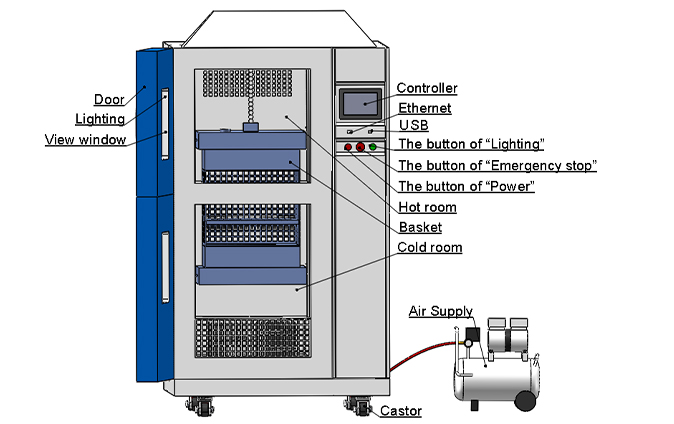

LIB Industry provides both two-chamber and three-chamber thermal shock test chambers, designed to meet different testing needs. Two-chamber models feature a high-temperature and a low-temperature zone with automatic basket movement, while three-chamber models include a dedicated test zone for flexible operation as either high-temperature, low-temperature, or full thermal shock testing systems.

The core of thermal shock testing lies in the three major working principles of LIB Industry temperature test chambers:

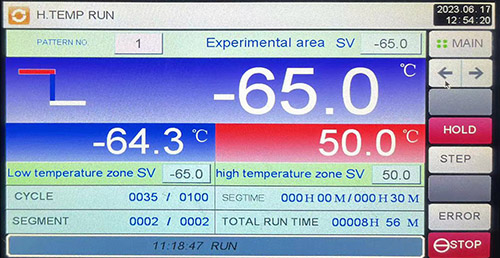

The high-temperature zone uses a comparison signal to regulate the on/off ratio of solid-state relays. Combined with the PID logic circuit of the programmable controller, this ensures precise heater output and automatic temperature control. Products are exposed to temperatures up to +200°C with fluctuations within ±0.5°C, allowing consistent simulation of thermal stress.

In the low-temperature zone, refrigerant passes through a throttling valve into the evaporator inside the chamber. Here, it absorbs heat from the test environment, vaporizes, and is drawn back into the compressor. This cycle enables rapid cooling down to –65°C, with full recovery in under 5 minutes. The process ensures accurate and reliable low-temperature exposure for each test sample.

2 Types of Thermal Shock Test Chambers High and Low-Temperature Zone | |

|

|

For three-chamber thermal shock test chambers, the test zone operates via automatic high- and low-temperature air valves. By switching between hot and cold air circuits, a closed-loop air circulation system forms with either the high-temperature or low-temperature chamber, enabling rapid temperature alternation without moving the samples and ensuring stable, repeatable temperature cycling tests.

For two-chamber thermal shock test chambers, the sample basket is mechanically moved between the high-temperature and low-temperature zones. This alternation achieves the same thermal shock effect, allowing products to experience rapid temperature transitions, while the chamber maintains precise temperature control and consistent testing conditions.

|

|

2-zone thermal shock test chamber | 3-zone thermal shock test chamber |

These three principles work together to simulate real environmental thermal shocks, revealing chemical, physical, and mechanical changes in tested materials and components.

LIB Industry thermal shock test chambers are designed for high precision and reliability, with key specifications as follows:

Model | TS-162 | TS-340 | TS-500 |

Internal Dimensions (mm) | 300×300×250 | 450×450×3-60 | 650×650×500 |

Interior Volume | 22L | 72L | 211L |

Loading Capacity | 20kg | 30kg | 50kg |

High Temperature Range | +20°C ~ +200°C | ||

Low Temperature Range | –65°C ~ –5°C | ||

Heating Time | Ambient → +200°C within 30 min | ||

Cooling Time | Ambient → –70°C within 30 min | ||

Temperature Fluctuation | ≤ ±0.5°C | ||

Temperature Recovery | ≤ 5 min | ||

Controller | Programmable LCD touch screen, Ethernet connection | ||

Interior Material | SUS304 stainless steel | ||

Standard Configuration | 2 shelves | ||

| |||

The thermal test equipment complies with IEC 60068-2-14, MIL-STD-883H, ensuring international testing credibility. This makes LIB Industry chambers suitable for quality assurance, product development, and regulatory compliance testing.

In addition to standard two-chamber and three-chamber thermal shock test chambers, LIB Industry offers a variety of customized solutions for specialized testing requirements, including:

Thermal Shock Test Chambers Series | |

| Liquid-to-Liquid Thermal Shock Chamber Liquid-to-Air Thermal Shock |

These custom configurations allow engineers to replicate extreme environments.

An automotive electronics manufacturer tested a temperature sensor module designed for engine compartments. The goal was to assess whether the module could withstand repeated cycles from –65°C to +150°C.

Test Process: - 10 sensors were fixed in the test zone of a three-chamber thermal shock test chamber (Model TS-340).

- Each cycle: 30 minutes in low-temperature zone, <10 seconds transfer, then 30 minutes in high-temperature zone.

- 100 cycles were performed, continuously monitored via data acquisition.

Results: All sensors maintained full functionality. One showed minor deviation within tolerance, while others remained stable. The LIB Industry thermal shock test chamber delivered rapid, stable temperature transitions and repeatable test conditions, providing accurate reliability data for the client.

This case demonstrates how LIB Industry chambers help engineers verify durability, optimize design, and reduce warranty risk.

1. Over 16 years of experience in environmental test chamber manufacturing.

2. High-precision temperature control (±0.5°C) and rapid recovery (≤5 minutes).

3. Flexible configurations: two-chamber or three-chamber models for diverse applications.

4. CE and ISO-certified, ensuring international compliance.

you receive:

- 3-year warranty covering parts and performance

- Lifetime technical support for installation, calibration, and troubleshooting

- Global service network for rapid response

Contact LIB Industry inquiry@libtestchamber.com to customize your thermal shock test chamber solution. Ensure your products withstand extreme conditions, enhance quality, and gain the confidence of your customers through professional temperature cycling tests.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia