Features and Benefits of Portable Thermal Chamber

1. Small and Solid: Portable thermal environmental chamber is designed in a simple, compact style, and the exterior material is made of SUS 304with a treated surface that is high temperature, rust and corrosion resistant. Small size makes it easy to place on a laboratory table, workbench or other limited space.

2. Environment Simulation: The portable thermal chamber enables simulating a wide range of environmental conditions, precise temperature control ranging from -20°C to +150°C, humidity in the relative humidity range of 10% to 98%. There are three temperature range types chamber that you can choose from.

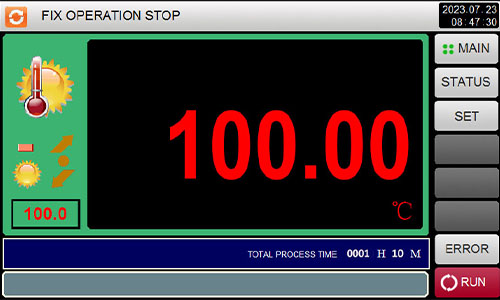

3. Precise Control and Adjustment: Advanced sensors and controllers ensure that the control accuracy of temperature, humidity, and the temperature control accuracy is within ±0.5℃. Through the PID control system, users can easily set and adjust the test parameters, and real-time monitoring and recording of the data changes during the test.

4. Quality and After-sales service: Before the delivery, we conduct performance testing, functional inspection, commissioning test, calibration, and issue reports on every step to guarantee quality.3 years warranty, lifetime service.

Specifications of Portable Thermal Chamber

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

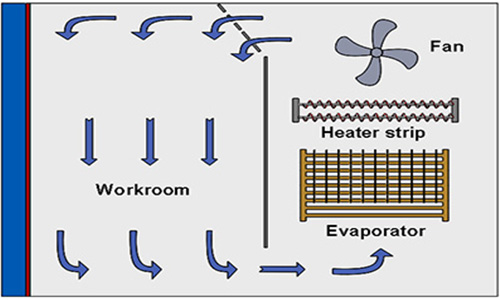

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

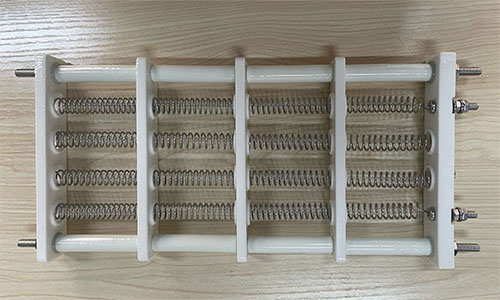

Cooling system | Mechanical compression refrigeration system |

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

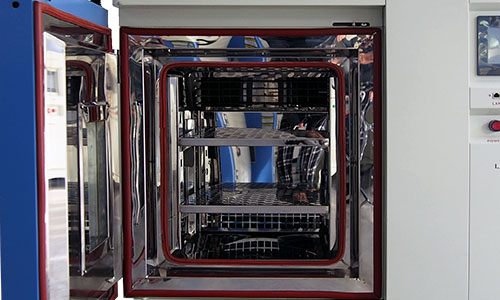

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

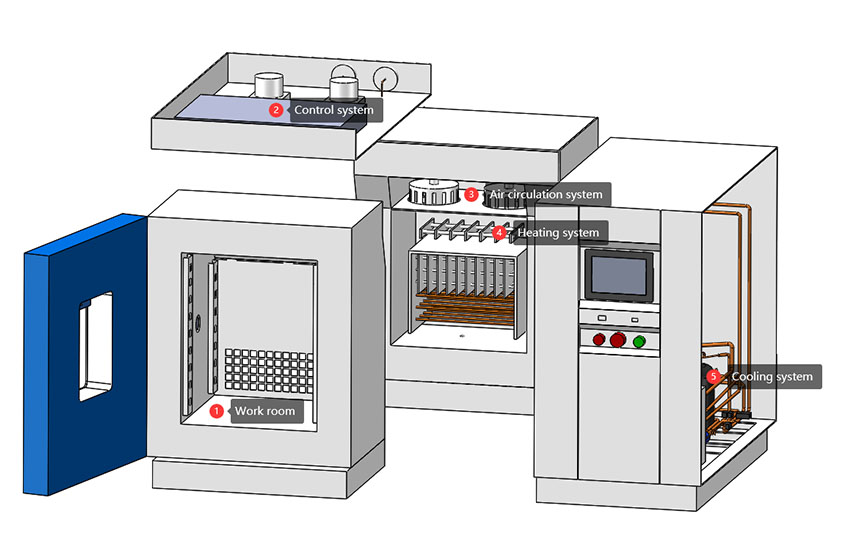

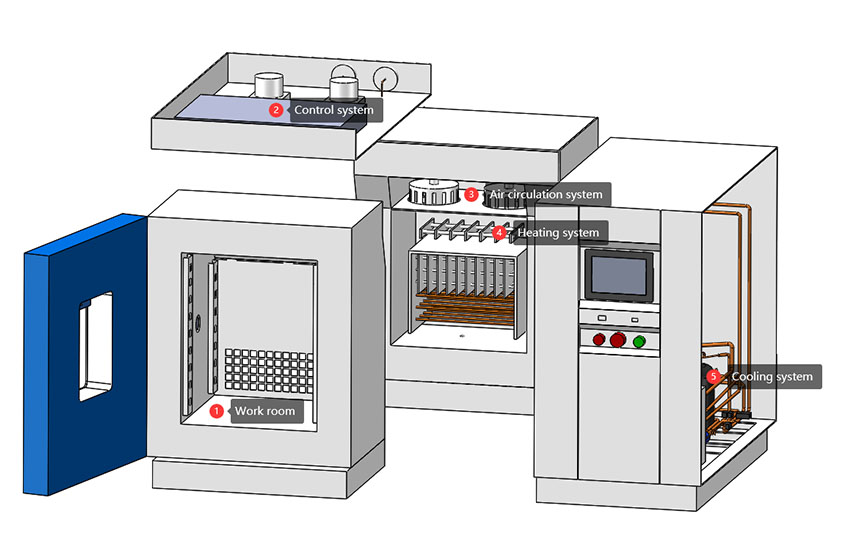

Configuration of Portable Thermal Chamber

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español