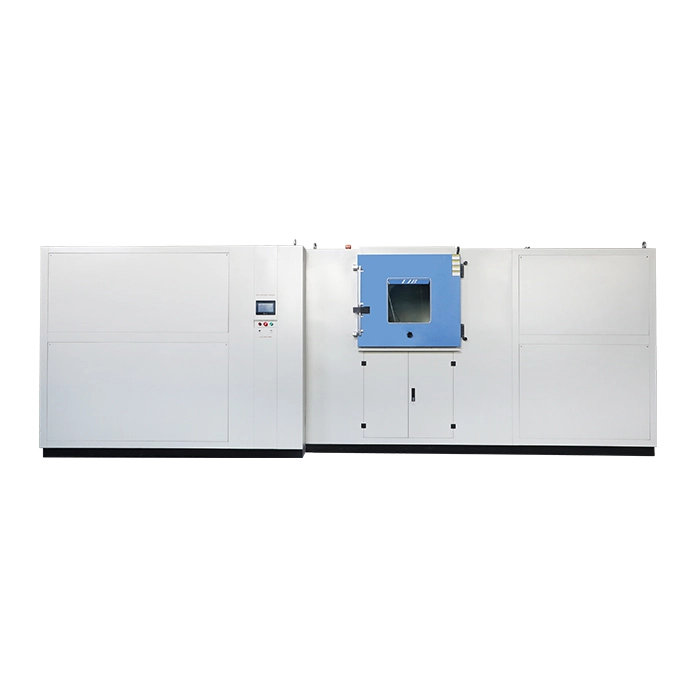

Damp Heat Chamber Features and Benefits

1. Equipped with high precision temperature and humidity probe, the heating, cooling, humidity and dehumidification systems work together to quickly respond to the needs of temperature and humidity changes.

2. Damp heat chamber can simulate a variety of complex temperature and humidity environmental conditions, such as high temperature and humidity, low temperature and humidity, and so on.

3. Good insulation and sealing performance, maintains the stability of temperature and humidity, ensures that the test can be carried out continuously and stably, and avoids affecting the test results due to environmental fluctuations.

4. The optimized refrigeration system, environmentally friendly refrigerant and intelligent control algorithm reduce the energy consumption and operating cost under the premise of meeting the test requirements.

Damp Heat Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

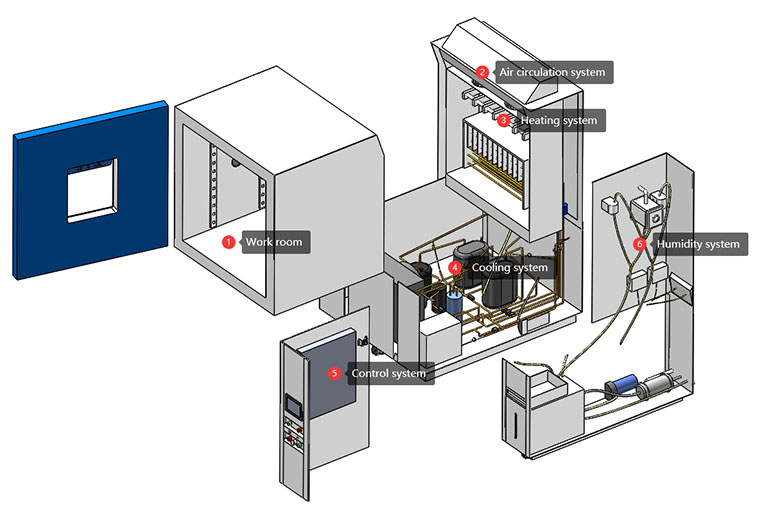

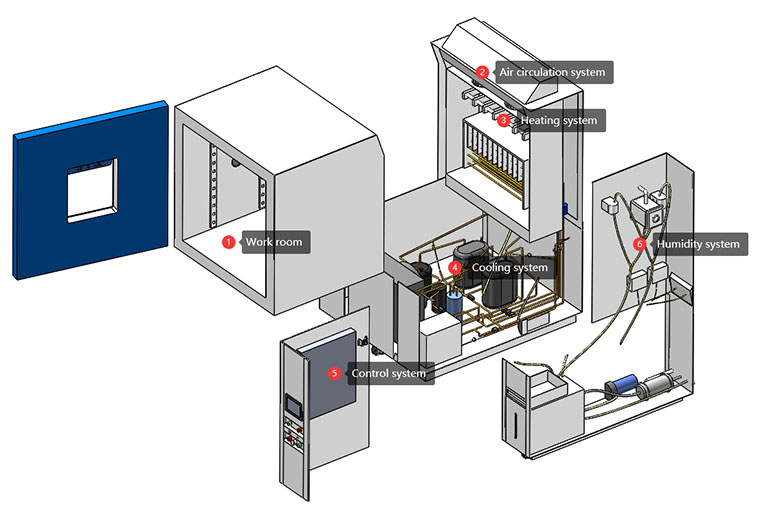

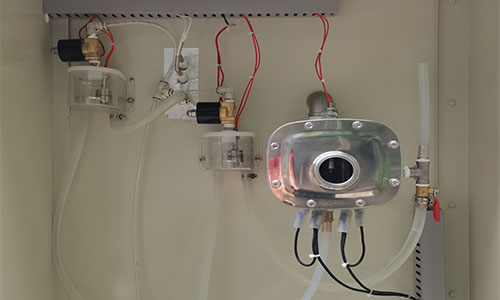

Configuration of Damp Heat Chamber

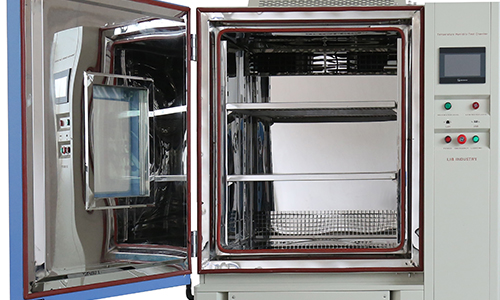

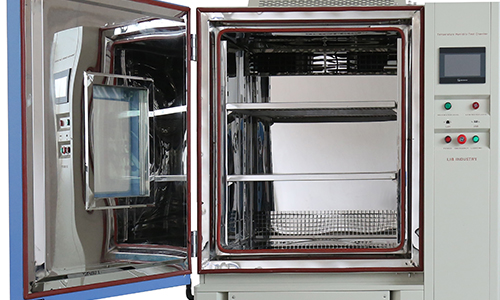

①Workroom | SUS 304 stainless steel material, with good corrosion resistance, high temperature resistance, moisture resistance. Two layers of standard perforated sample holder for easy gas flow. The PT-100 Class A sensor with an accuracy at 0.001 degrees.A wet gauze and a real-time temperature, converted by temperature difference, showing real-time relative humidity.

|  |

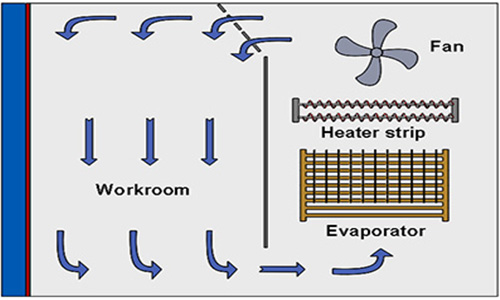

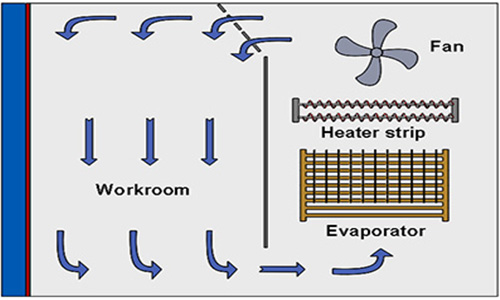

②Air circulation system | It consists of a centrifugal fan and a motor. Large air volume, high wind pressure and stable operation make the temperature and humidity distribution inside the Workroom more uniform. |  |

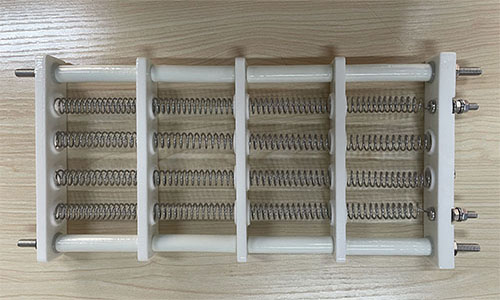

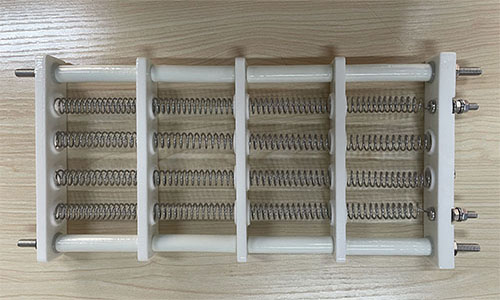

③Heating system | Electric heating element is used. High heating efficiency, fast heating rate of 3℃/min. |  |

④Cooling system | Refrigeration compressor is used for refrigeration. Refrigeration system also includes condenser, throttling device, evaporator. |  |

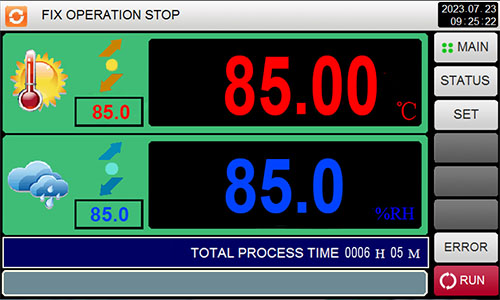

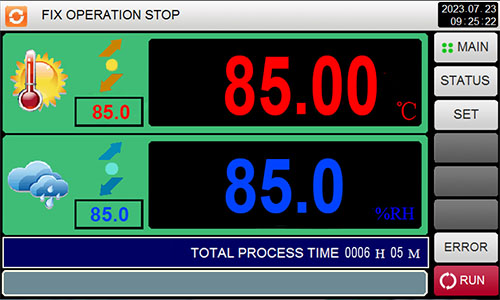

⑤Control system | Users can easily set such as temperature, humidity, test time, etc. through the touch-screen operation interface, and can view the running data and status of the test chamber in real time for data acquisition and recording. |  |

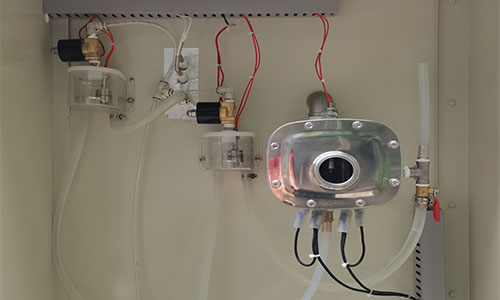

⑥Humidity system | Steam humidification method is adopted, and the humidification system should have a stable water supply system. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español