Thermal shock test chamber is a rapidly changing temperature to simulate products under extreme temperature changes may occur in the environment of thermal stress of the equipment. It is widely used in electronics, automotive, aerospace and other industries to test the durability, reliability and thermal expansion characteristics of materials and products under thermal stress.

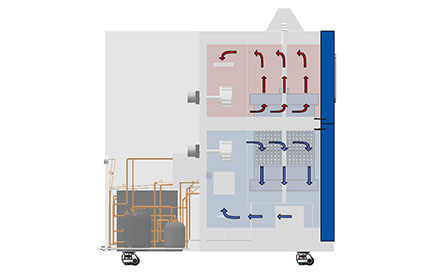

1. Fast heating and cooling: Thermal shock test chamber with efficient heating system and cooling system. With heaters and coolers, the temperature in the chamber can be quickly raised or lowered.

2. Temperature control area: Part of the thermal shock test chamber is a high temperature area and a low temperature area, and the test sample is placed in a temperature environment that can quickly switch from one extreme temperature to another.

The thermal shock test chamber produced by LIB, using the latest temperature control technology, offers the following significant advantages:

1) The equipment can accurately control the internal temperature of the cavity through the advanced PID temperature control system, and the error range can be controlled within ±0.5℃.

2) Wide temperature range, -70℃ to +220℃ temperature setting, so that the thermal shock test chamber can simulate the extreme environment from cold to high temperature, to meet the test needs of different products.

1) The equipment adopts high-speed compressor and efficient heating elements to make the temperature change fast and stable.

2) The fast switching function of thermal shock test can effectively simulate the instantaneous temperature changes encountered in actual use of the product.

1. Double temperature zone design is adopted, low temperature zone and high temperature zone are isolated by high and low temperature insulation materials to ensure small and stable temperature fluctuations during the test. The sample can be moved through the low temperature zone and the high temperature zone by carrying the basket to achieve instant severe temperature changes.

2. High-quality temperature control system, so that the equipment in long-term operation to maintain excellent stability, not affected by environmental changes.

Thermal shock test chamber can not only test electronic components, automotive parts, aerospace materials, etc., but also test the performance of special materials such as glass and ceramics under extreme temperature differences. By precisely controlling the temperature change rate, the LIB thermal shock test chamber can effectively evaluate whether the material will crack, deformation, structural damage and other problems under temperature sudden change.

Temperature range: -70℃~ +220℃

Temperature accuracy: ±0.5°C

Control mode: PID intelligent control

Test chamber volume: 100L to 1000L (customizable)

If you have any needs or questions about the thermal shock test chamber, please feel free to contact us and we will tailor a solution for you.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español