Thermal shock tests, also known as temperature shock tests or high-low temperature thermal shock tests, simulate severe temperature changes that a product may experience during design, development, production, transportation, installation, and use. These tests mainly verify the ability of a test sample’s structural components to withstand thermal expansion and contraction. To some extent, thermal shock tests are considered destructive tests.

Rapid temperature change tests are part of Environmental Stress Screening (ESS) and are an efficient method to improve product reliability.

· Thermal Shock Test Chambers: These are essential for industries dealing with materials such as metals, plastics, rubber, and electronics. They test the chemical or physical damage caused by sudden, extreme temperature changes to the structure of materials or composite materials. Typically, two-zone or three-zone thermal shock test chambers are used.

· Rapid Temperature Change Test Chambers: These tests expose potential early failures in electronic products due to defective components, manufacturing processes, or other reasons during R&D, design, and production stages. Rapid temperature change test chambers (also known as ESS chambers) are used to screen for potential climatic, thermal, or mechanical stresses that could cause premature failure.

· Thermal Shock Tests: Mainly conducted during the R&D and prototype stages.

· Rapid Temperature Change Tests: Primarily used in mass production stages.

· Thermal Shock Test Chambers: Mainly used to test the structure of materials or composite materials, and most commonly used for components or assemblies of electronic products (e.g., PCBs, ICs).

· Rapid Temperature Change Test Chambers: Mainly suitable for electronic components, assemblies, and equipment.

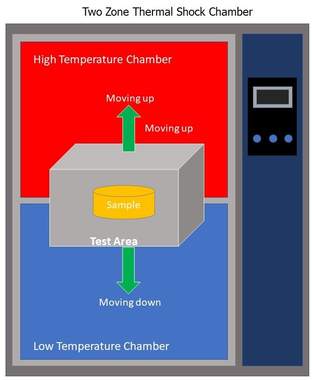

· Thermal Shock Test Chambers: Designed for thermal shock testing, they have a different internal structure from rapid temperature change chambers. Thermal shock chambers have two temperature zones: high and low. They come in two-zone and three-zone designs. The two-zone thermal shock chamber moves the test item back and forth between the high and low-temperature zones, creating a thermal shock effect. The three-zone thermal shock chamber has separate high, low, and testing zones. During the test, the item is placed in the testing zone, where alternating hot and cold air streams from the high and low zones create the thermal shock effect.

· Rapid Temperature Change Test Chambers: Unlike thermal shock chambers, they only have one chamber, where the temperature changes (heating or cooling) occur. Due to the rapid rate of temperature change, these chambers are also called rapid temperature change chambers. They do not achieve the instantaneous effects of thermal shock chambers.

· Thermal Shock Tests: The temperature change occurs within 5 minutes to switch between high and low temperatures, with the temperature change being instantaneous and non-linear. The goal is to create a thermal shock.

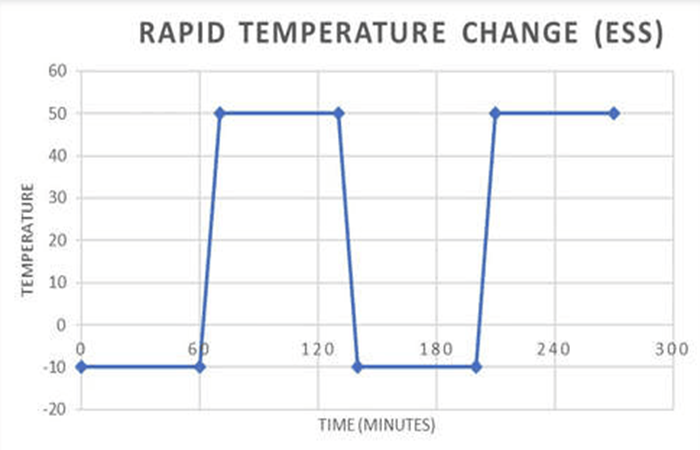

· Rapid Temperature Change Tests: The temperature changes are completed within a specified time, and can be linear or non-linear. For example, a device with a temperature range from -40℃ to 80℃ might take 24 minutes to cool from 80℃ to -40℃ at a rate of 5℃/min. This is slower than thermal shock but much faster than conventional high-low temperature chambers.

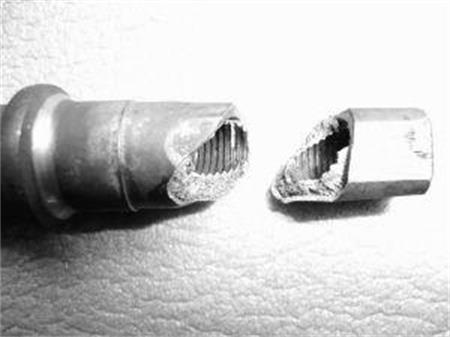

· Thermal Shock: Failures are caused by material creep and fatigue damage, often referred to as brittle failures.

· Rapid Temperature Change: Failures are primarily due to material fatigue.

· Thermal Shock: Failures may include deformation or cracking of parts, insulation breakdown, jamming or loosening of moving parts, changes in electrical and electronic components, or electronic/mechanical failures due to rapid condensation or frost.

· Rapid Temperature Change: Failures may include the expansion of micro-cracks in coatings, materials, or wire ends; loosening of poorly bonded joints; loosening of screw connections or riveted joints; failures caused by deformation and stress due to different thermal expansion coefficients, decreased insulation of encapsulating materials, inadequate mechanical tension, and increased contact resistance in poor solder joints.

· Thermal Shock Test Standards:

o GB/T 2423.22-2012

o IEC 60068-2-14:2009

o GJB 150.5A-2009

o GB/T 28046.4-2011

· Rapid Temperature Change Test Standards:

o GB/T 2423.22

o IEC 60068-2-14

o GJB 150.5