UL 50E is the UL certification standard for Environmental considerations of electrical equipment enclosures. The standard covers additional environmental structural and performance requirements of enclosures for electrical equipment with environmental considerations. The standard is applicable to the United States, Mexico and Canada markets.

The UL 50E standard applies to enclosures of electrical equipment installed and used in non-hazardous locations in accordance with Canadian Electrical Code Part I CSA C22.1 and National Electrical Code NFPA 70. The regulations of the Mexican electrical UL 50E shower NOM-001-SEDE are as follows:

1) Enclosures for indoor places, types 1, 2, 5, 12, 12K and 13;

2) Enclosures for indoor or outdoor locations, types 3, 3R, 3S, 4, 4X, 6 and 6P.

UL 50E covers the additional environmental structure and performance requirements of the enclosure. General requirements for enclosures are contained in standards CSA C22.2 No. 94.1, UL 50 and NMX-J-235/1-ANCE or in conjunction with this standard for end-use products.

The UL 50E test includes the following tests: drip test, rain test, dust test, external icing test, hose test, indoor corrosion protection, outdoor corrosion protection, immersion test, pressure test, oil exclusion test, washer test, rod entry test, misalignment test, water exposure and immersion test. This article only discusses the water exposure and immersion test in the UL 50E standard, introducing the UL 50E shower.

The main function of the UL 50E shower is to test the physical and other related properties of electronic, electrical products, lamps, electrical cabinets, electrical components and other products under simulated rainy weather conditions. After the test, through the verification to determine whether the performance of the product meets the requirements, in order to facilitate the design, improvement, verification and factory inspection of the product.

UL 50E shower mainly simulates various conditions of natural rainfall, including the size, speed, rainfall, rainfall Angle, etc., to spray the tested product.

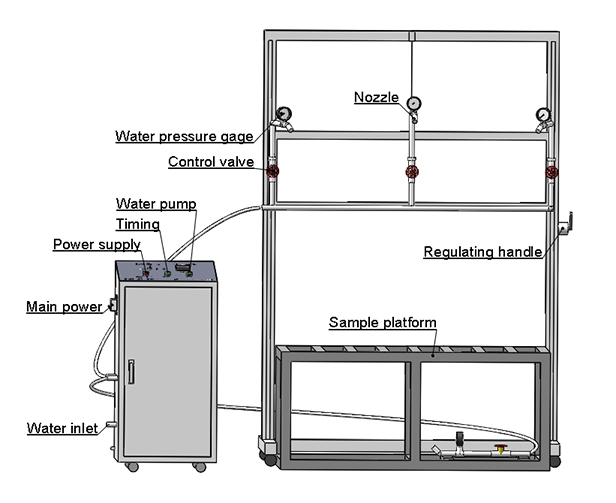

The UL 50E shower usually consists of the following:

1. Water supply system: responsible for providing clean and stable water source, and controlling water pressure and water flow speed through pressure regulating UL 50E shower.

2. Water spray system: consists of a number of carefully designed sprinkler heads to ensure that the distribution and characteristics of raindrops meet the standard requirements.

3. Control system: used to set and control the parameters of the rain test, such as the rain time, rainfall, etc., and real-time monitoring and recording of the test data.

At work, water is delivered through the water supply system to the nozzle, and then sprayed in a specific way to form a simulated rainfall. The tested product is placed on a fixed UL 50E shower in the rain room and is sprayed with rain water. By controlling different parameters, different intensity and types of rainfall can be simulated.

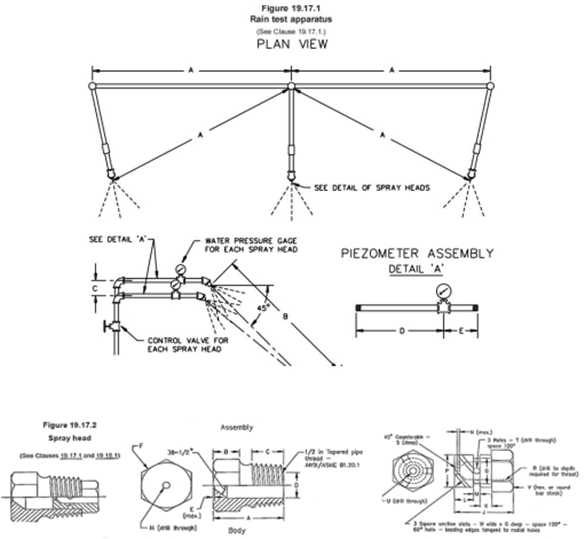

1. Number of nozzles and injection Angle, the injection Angle is 45°.

2. Water spray pressure, generally 34.5Kpa or adjustable to meet different test requirements.

3. The nozzle water column junction height is adjustable, the range may be from 300mm to 1200mm or 1000mm to 2000mm.

4. The test time is adjustable and can be set from 0 to 99999.9 minutes.

5. The support material may be formed aluminum material or industrial aluminum profile, and the base be equipped with universal belt brake caster.

6. Structure and function: The UL 50E shower may include components such as sprinkler heads, supports, pressure gauges, etc. The spacing and structure design of sprinkler heads must comply with the specific UL standard graphic requirements.

Model | R-UL020 | |

Overall Dimensions (mm) | 800*1500*3800mm | |

Height adjustment range of spray device | 1000-3600mm(Adjustable) | |

Parameter | Number of spray head | 3 spray heads |

Nozzle spacing | 710mm | |

Spraying Hole Diameter | Φ5mm | |

Water pressure | 34.5Kpa | |

Sample platform size | 1000X1400X500mm | |

Load of sample platform load | 100 Kgs | |

| ||

| ||

LIB UL 50E shower is excellent in the above technical parameters:

a. Using advanced nozzle manufacturing process to ensure that the uniformity of raindrop distribution is higher than the industry standard;

b. The unique pressure adjustment system can not only accurately maintain the set pressure, but also has the automatic compensation function of pressure fluctuation to ensure the test stability;

c. The nozzle height adjustment adopts electric control, convenient operation and high precision;

d. The test time control is accurate to 0.1 minutes, which provides a strong guarantee for scientific research level testing;

e. The support structure has been strengthened to ensure stability and reduce the overall weight of the equipment, which is convenient for transportation and installation.

f. Unique intelligent control system can realize remote monitoring and data recording, which greatly improves the test efficiency and management convenience.

1. Electronic and electrical products

Including mobile phones, computers, tablets, chargers, electrical housings, etc., to ensure that these products can still work normally in a humid environment, to prevent short circuit, failure and other problems caused by water.

2. Auto parts

Car headlights, taillights, dashboards, sensors, electronic control units and other components need to have good waterproof performance to adapt to various weather conditions.

3. Outdoor equipment

Street lights, surveillance cameras, communication equipment, solar panels and other outdoor equipment are often exposed to rain environment, through the rain test can verify its protection ability.

4. Aerospace

Aircraft parts, spacecraft housings, etc., require very high water resistance, and UL 50E showers help ensure that they maintain normal operation in harsh weather conditions.

See here, I believe you have a certain understanding of UL 50E shower, if you are worrying about the waterproof performance test of the product, LIB UL 50E shower will be your ideal choice. Its precise technical parameters, reliable performance and excellent brand reputation can provide a solid guarantee for the quality of your products. Contact us today inquiry@libtestchamber.com for more product details and special offers!