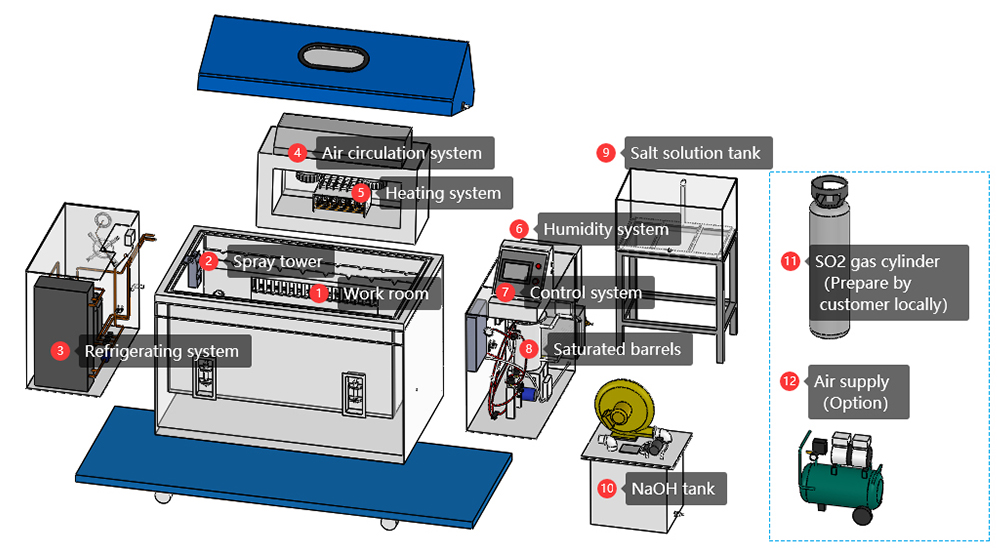

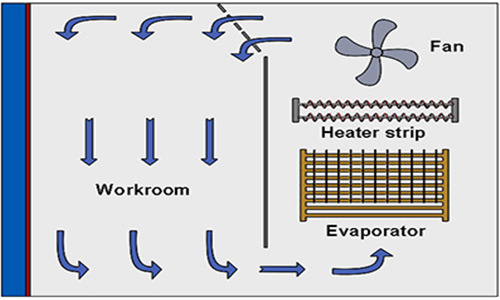

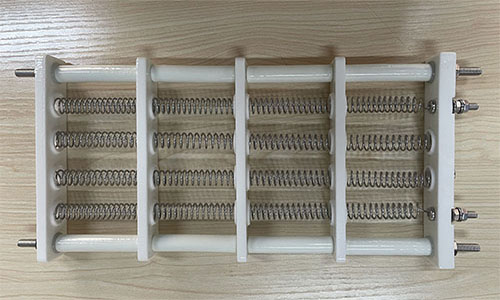

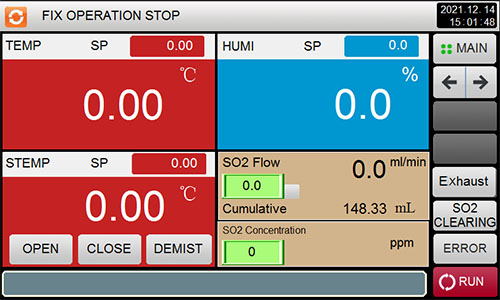

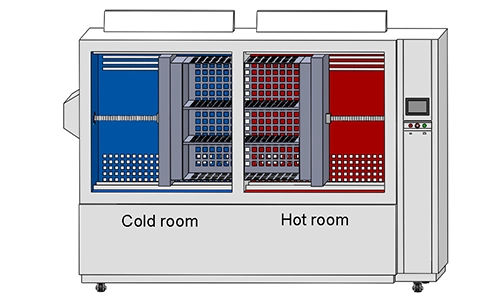

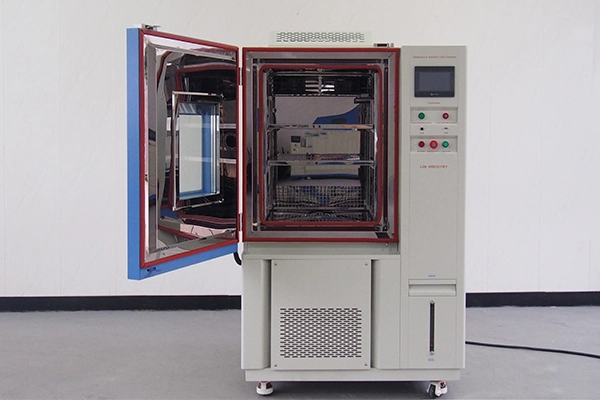

LIB salt fog and SO2 corrosion chamber generates the different environment conditions that combining salt spray with temperature, humidity, SO2 gas, drying, wetting for corrosion test of products. We can build a new salt spray corrosion laboratory for customers, providing one-stop solutions for communication, production, delivery, installation and operation.

Model: SSC-010, SSC-016, SSC-020

Standard: ASTM B117, ISO 9227, ASTM G85, D17 2028, SAE J2334, ISO4611, ISO7253, BS3900-F12, BS7479, IEC 60068-2-11, DIN 50021.ASTM G85-02e1 Annex A1, ISO9227, DIN 50021, BS 7479, ASTM B368, ISO9227, DIN 50021, BS 7480

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español