As an efficient and lightweight energy storage device, lithium-ion batteries are widely used in many fields such as smart phones, electric vehicles, and portable electronic devices. However, there are certain safety risks in the use of lithium-ion batteries, such as thermal runaway, short circuit, overcharge and overdischarge problems, which may not only lead to the deterioration of battery performance, but also may cause serious accidents such as fire and explosion.

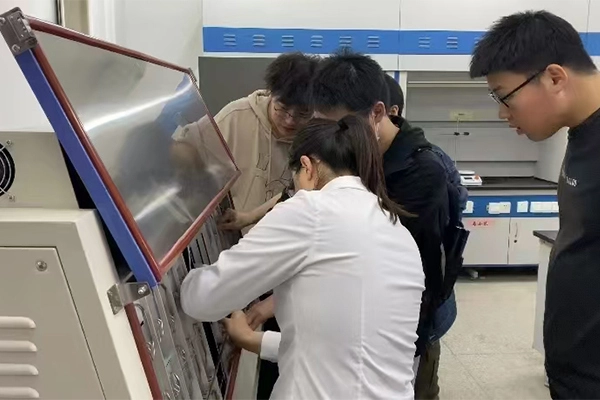

How to improve the safety and performance of lithium-ion batteries has become the focus of attention of researchers and enterprises. The battery test chamber, as a device specially used for battery testing and research, plays a crucial role in improving the safety and performance of lithium-ion batteries.

Temperature is one of the key factors affecting the performance and safety of lithium-ion batteries. At high temperatures, the rate of chemical reactions inside the battery is accelerated, which leads to the attenuation of the battery capacity. High temperature will also increase the internal resistance of the battery, thereby reducing the charge and discharge efficiency. What's more, high temperatures can trigger thermal runaway. When the internal temperature of the battery is too high, the electrolyte may decompose to produce flammable gas, and the positive and negative electrode materials of the battery will also react violently, releasing a lot of heat, further aggravating the rise in temperature, and eventually leading to a battery fire or explosion.

On the contrary, at low temperatures, the chemical reaction inside the battery becomes slow, and the diffusion rate of lithium ions slows down, which will cause the capacity of the battery to decrease significantly, and may even be unable to charge or discharge.

Excessive humidity may cause rust and corrosion of the metal components inside the battery, which affects the conductivity and stability of the battery. The wet environment may also make the battery electrolyte hydrolysis reaction, change the chemical properties of the electrolyte, and then affect the performance of the battery. In addition, water entering the battery may cause short circuit failure, which seriously threatens the safety of the battery.

During the charging and discharging process of the battery, the phase transition and chemical reaction of the substance will occur inside the battery, resulting in a change in pressure. If the pressure is too large, it may cause the battery shell to deform, crack, and destroy the overall structural integrity of the battery. Changes in pressure may also affect the contact between the electrode material and the collector fluid, which in turn affects the charge and discharge performance of the battery.

The temperature control system of the battery test chamber quickly and accurately adjusts the temperature in the chamber through the heating or cooling device according to the set temperature value.LIB battery test chamber can achieve a temperature control accuracy of ±0.5 ° C, and have the ability to quickly heat up and cool down, and can reach the set temperature conditions in a short time to meet different test needs.

The humidity control system simulates different humidity environments by controlling the humidity in the chamber to study the influence of humidity on the lithium-ion battery. The humidity adjustment range can usually be set between 10%RH and 98%RH, which can meet the requirements of most lithium-ion battery tests for humidity environments.

The battery test chamber can simulate the conditions under which thermal runaway occurs and help researchers to further study the triggering mechanism of thermal runaway. By gradually increasing the temperature in the test chamber and monitoring the changes of temperature, voltage, current and other parameters inside the battery, the occurrence process of thermal runaway phenomenon is observed. The study found that when the battery temperature exceeds a certain threshold, the electrolyte begins to decompose, producing a large amount of combustible gas, while the internal resistance of the battery rises sharply, the current increases instantaneously, causing thermal runaway.

Based on these research results, prevention strategies of thermal runaway can be developed. For example, improve the heat dissipation structure of the battery, increase the heat sink or use the liquid cooling system to improve the heat dissipation capacity of the battery in normal operation and abnormal heating; Optimize the electrolyte formulation, reduce its decomposition temperature and reactivity, and reduce the amount of combustible gas produced.

The safety threshold of lithium-ion batteries can be accurately determined by using the battery test chamber under various environmental conditions. The battery is overcharged, overdischarged, and short-circuited in different temperature, humidity, and pressure environments, and the parameter values are recorded when the battery is in danger of smoke, fire, and explosion. In a high temperature and humidity environment, the overcharge safety threshold of the battery may be reduced, and the overdischarge safety threshold may not change much. The comprehensive analysis of these tests in different environments can determine the safety threshold range of the battery under various working conditions, which provides an important basis for the design of the battery management system (BMS).

Future battery test chambers may have a more intelligent control system that can automatically adjust temperature, humidity, pressure and other parameters according to the preset test plan, and can analyze the test data in real time to provide more accurate optimization recommendations for developers. In addition, with the continuous improvement of lithium-ion battery performance and safety requirements in fields such as new energy vehicles and energy storage power stations, the battery test box will play a more important role in promoting technological innovation and industrial development of lithium-ion batteries, and contribute to the realization of more efficient, safe and environmentally friendly energy storage and utilization.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia