In the world of plastic products, ultraviolet (UV) tolerance is a key indicator of product quality and longevity. From the plastic panels for outdoor building decoration, to the plastic household items for daily use, and even the plastic parts in the interior of the car, all face the "attack" of ultraviolet light. At this time, a professional and accurate UV weathering test chamber has become a necessary tool to control the quality of plastic, and the LIB brand UV weathering test chamber is one of the best.

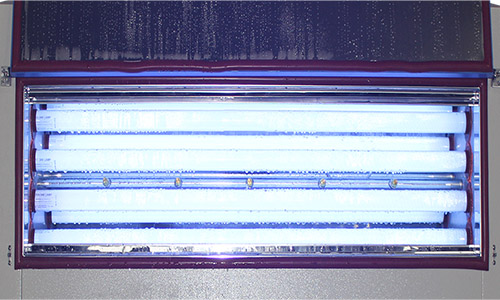

Open the door of the LIB UV test chamber, the internal layout is clear at a glance, and the spacious test space can accommodate plastic samples of various sizes, from fine plastic accessories to large plastic sheets can be easily placed, and the light and temperature and humidity environment at each location are uniform, ensuring that the test results are without bias.

The core advantage of this test chamber is first reflected in its accurate UV irradiation system. Its irradiation intensity range accurately covers from 0.3W/m² to 1.5W/m², whether it is to simulate the soft spring morning daylight, or the blazing summer sun, it can output just the right UV dose through intelligent adjustment, so that plastic samples in the laboratory ahead of outdoor years or even decades of light test. The operator only needs to input the target irradiation intensity on the convenient touch panel, and the system's built-in high-precision light sensor will give real-time feedback and automatically calibrate, controlling the irradiation fluctuation within a very small range to ensure the high precision and high repeatability of the test.

At the same time, the temperature control system is equally excellent. The temperature range ranges from ambient temperature to 70°C, a wide range that simulates cool morning outdoor temperatures and recreates the heat of a hot afternoon. With ultraviolet radiation, it is true to reduce the climate challenges faced by plastic products in different seasons and different regions. Advanced air cooling and heating devices work together to form a stable air circulation in the chamber, so that the temperature is evenly distributed, avoid local overheating or undercooling, and further improve the reliability of the test.

Not only that, the LIB UV test chamber takes into account long-term user convenience. The operation interface is simple and easy to understand, and the newly started experimentalists can also quickly master the operation of various functions, greatly reducing the training cost and the probability of misoperation.

For plastic products companies, having a LIB UV test chamber is equivalent to holding the key to the high-end quality market. It can help enterprises to screen out the material formula with excellent UV resistance in advance, optimize product design, avoid product discoloration, brittleness, cracking and other quality problems caused by UV aging, and greatly improve product competitiveness.

At present, the market for the appearance and durability of plastic products are increasingly demanding, if you want to accurately control the UV tolerance of plastic products, so that products in the outdoor environment, then contact us inquiry@libtestchamber.com as soon as possible! The professional team will provide you with a comprehensive interpretation of the powerful functions of the LIB UV test chamber and provide tailor-made test solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español