Features and Benefits of Carbon Dioxide Sulfur Dioxide Spray Chamber

1. The multi-gas composite corrosion environment simulation not only supports the individual or combined testing of SO₂ / CO₂, but also can be expanded to include gases such as Cl₂, NH₃, and H₂S.

2. The temperature and humidity range is wide and precisely controlled. The temperature control range is 15℃ to 80℃, and the humidity range is 50 to 98%RH, with accuracies of ± 0.5 ℃ and ±2.5%RH respectively.

3. High-precision flowmeters monitor and control gas flow in real time, and provide real-time feedback to achieve dynamic concentration adjustment of gas. The gas control accuracy can reach ±1%, ensuring stable gas release and uniform distribution.

4. High safety, double-sealed cabin door design,316 stainless steel workroom material, suitable for strong acid and strong corrosion environments. Toxic gas after the dilution test of the NaOH solution tank.

Specifications of Carbon Dioxide Sulfur Dioxide Spray Chamber

Model | GCM-100 | GCM-225 | GCM-500 |

Internal Dimensions (mm) | 400*500*500 | 500*600*750 | 700*800*900 |

Overall Dimensions (mm) | 1010*1050*1620 | 1110*1150*1860 | 1330*1350*2010 |

Interior Volume (L) | 100 | 225 | 500 |

Temperature Range | 15 ℃ ~ 80 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | ±2.5% RH |

SO2 Concentration | 100 ~500 ppb± 20 ppb (Adjustable) |

H2SConcentration | 10 ~100 ppb ± 20 ppb (Adjustable) |

NO2Concentration | 200 ppb ± 20 ppb (Adjustable) |

Cl2concentration | 10 ~20 ppb ±5 ppb (Adjustable) |

Air Change Rate | 3~10times /h |

Gas Sensor | H2S/NO2/CL2/SO² gas sensor |

Air Circulation | Centrifugal wind fan |

Door Lock | Electromagnetic lock |

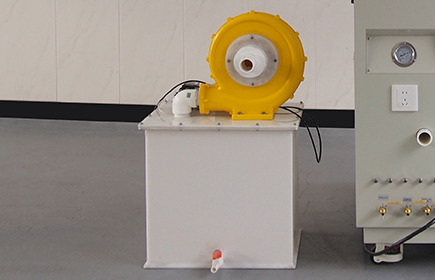

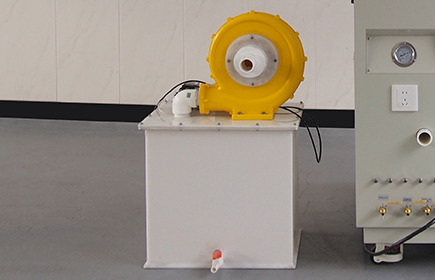

Gas Exhaust Device | Exhaust Unit |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Interior material | SUS304 stainless steel +Glass fiber reinforced plastics |

Details of Carbon Dioxide Sulfur Dioxide Spray Chamber

|

Workroom | Flow Meter |

SUS 316 material, the capacity of the workroom can be customized, equipped with high-precision temperature and humidity probes. The electromagnetic lock on the door prevents misoperation.

| Adjust the gas injection rate to ensure the stability of the test gas concentration. |

|  |

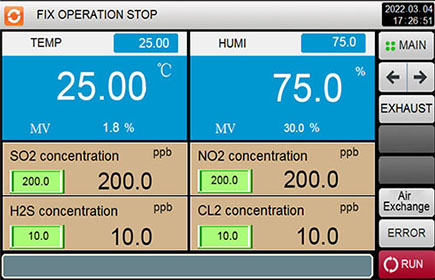

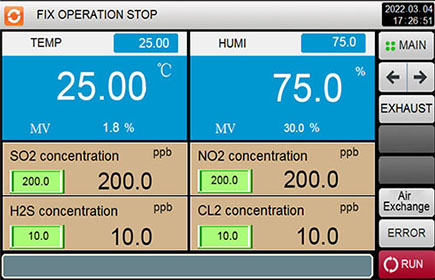

Intelligent Controller | Residual Gas Treatment |

The PLC touch screen centrally controls factors such as temperature, humidity, gas injection time, and spray circulation. Support program editing, multi-segment control, data recording, and remote monitoring.

| NaOH Solution Tank, neutralizing and absorbing acidic waste gas, with an internal spray device to accelerate the chemical absorption process. |

|  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español