Under the background of the continuous upgrading of building energy conservation, as the main channel for building heat loss, the thermal stability assessment of walls has become an important means to evaluate the energy efficiency performance of building components.

By measuring the thermal conduction performance of the wall in a stable thermal environment, its heat transfer coefficient (U value) and thermal resistance (R value) can be scientifically obtained, providing an important basis for building energy-saving design and material development.

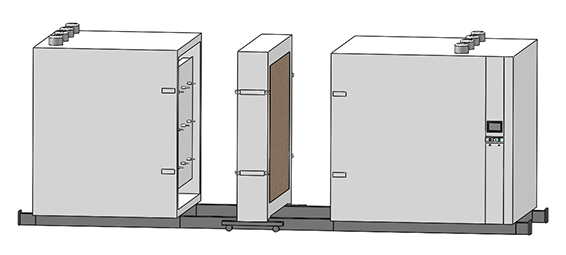

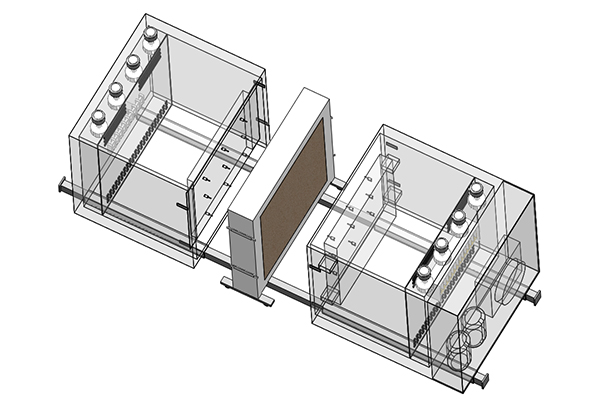

To meet such precise requirements, LIB has custom-developed a professional test chamber system for testing the thermal conductivity performance of walls. This equipment adopts a structural layout with a hot chamber on one side and a cold chamber on the other. The wall specimens to be tested are vertically installed in the middle to achieve a steady-state heat transfer environment that simulates the direction of natural heat flow.

The hot chamber and the cold chamber are two independent working areas. They maintain the set temperatures respectively through a high-precision temperature control system to form a stable temperature difference.

Although it is an independent structure, LIB achieves a high degree of sealing in the equipment connection structure, ensuring no heat leakage during the test. The heat flow is only transferred through the wall itself, meeting the test requirement of "unidirectional heat flow" in the standard.

Nine high-precision temperature probes are installed in each studio. Some are used to monitor the ambient temperature inside the cabin, while others are directly installed at key positions on the wall to accurately collect the temperature gradient and temperature field distribution during the heat transfer process, providing a solid foundation for steady-state determination and data analysis.

This equipment not only complies with the structural and testing procedures stipulated by relevant international regulations, but also supports the thermal performance testing of building components such as walls of different sizes and composite wall panels. It is widely used in building materials factories, architectural design units, research institutions and universities.

The LIB test chamber system performs exceptionally well in terms of heat flow direction, temperature control accuracy, sealing structure design, and data acquisition reliability. The control system automatically records test data and generates data reports, significantly enhancing experimental efficiency and professionalism.

LIB customization capability, facilitating every testing requirement

LIB has a strong non-standard customization capability and can flexibly design exclusive solutions based on users' sample size, testing environment, control interface and other requirements.

Support various non-standard customizations (size, function, interface)

3-year full machine warranty, more peace of mind when using

24/7 online English customer service support

If you have any other special testing requirements, please feel free to contact the LIB team.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español