Features and Benefits of Thermal Shock Test Machine

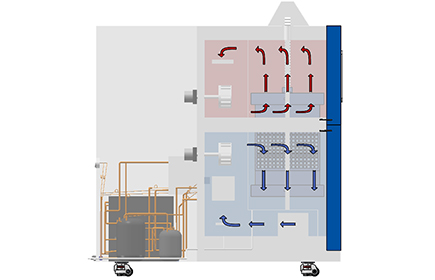

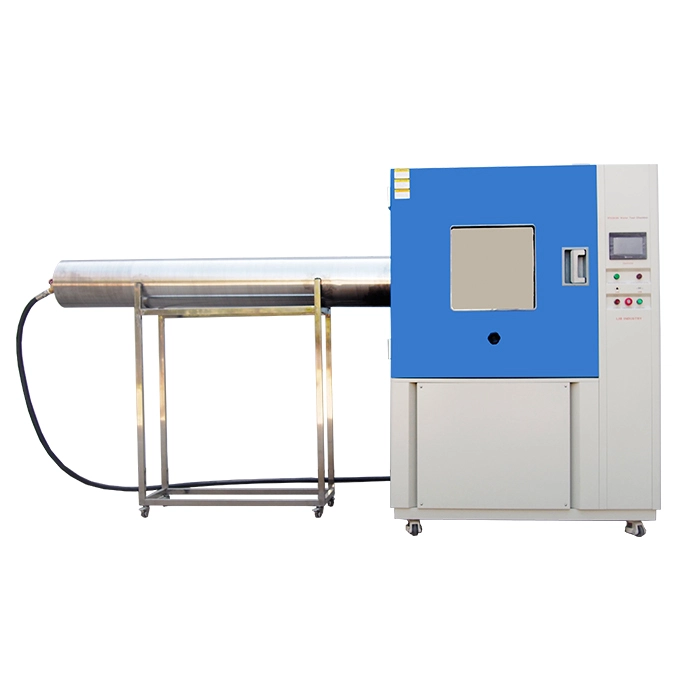

1. The pneumatic lifting system, with extremely rapid temperature zone switching, completes the thermal shock conversion within 3 seconds, meeting the standards such as IEC 60068-2-14 and MIL-STD-883 for "unbuffered temperature conversion".

2. Precise temperature control, with a fluctuation of ±0.5℃ and uniformity of ±2.0℃, ensures the consistency and reliability of test results.

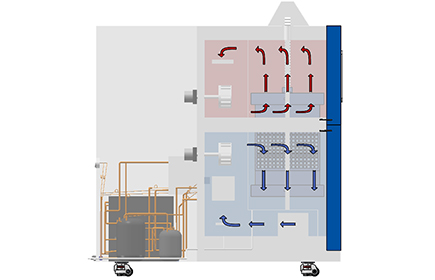

3. The two-box structure is more concise and has a smaller heat dissipation burden. During the test cycle, only two temperature zones need to operate alternately, reducing overall energy consumption and saving operating costs.

4. The thermal shock test machine adopts a vertical compact structure design, occupying less space. Combined with mobile casters, it can be flexibly deployed in laboratories or beside production lines.

Specifications of Thermal Shock Test Machine

Model | TS-162 | TS-340 | TS-500 | TS-1000 |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | 650*650*500 | 850*850*700 |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | 1910*1220*2265 | 2110*1420*2665 |

Interior Volume (mm) | 22L | 72L | 211L | 505L |

Loading Capacity | 20kg | 30kg | 50kg | 60kg |

Pre-heat Room | Upper limit Temperature | +220℃ |

Heating Time | Ambient ~ + 200℃, within 30 minutes |

Pre-cool Room | Lower limit Temperature | -75℃ |

Cooling time | Ambient ~ -70℃, within 30 minutes |

Test Room | High Temperature Exposure Range | Ambient +20 ~ +200°C |

Low temperature Exposure Range | –65 ~ -5°C |

Temperature Fluctuation | ≤±0.5℃ |

Temperature Deviation | ≤±3 ℃ |

Temperature Recovery Time | Within 5 minutes |

Cooling System | Mechanical compression refrigeration system |

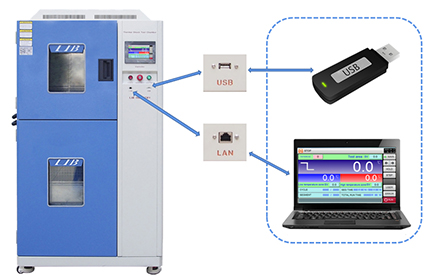

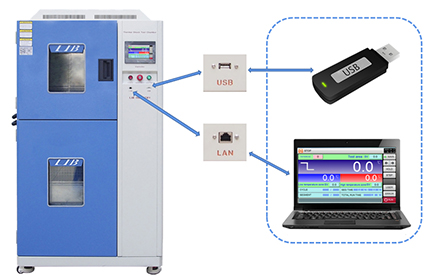

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

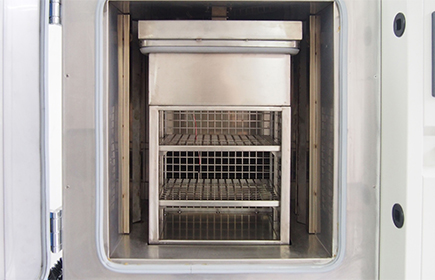

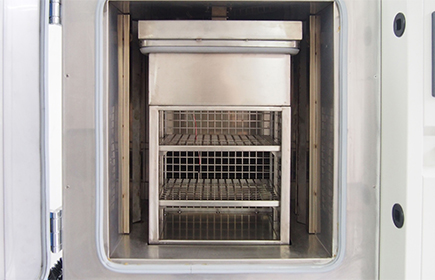

Standard Configuration | 2 shelves |

Details of Thermal Shock Test Machine

|

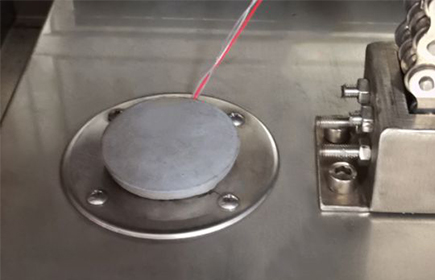

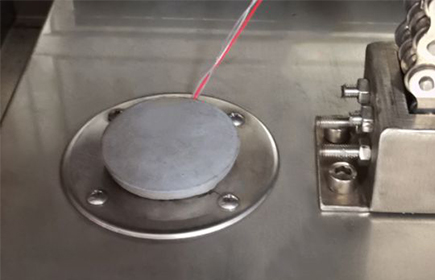

Basket | Cable Hole |

High-strength SUS304 stainless steel, with strong load-bearing capacity (20KG), corrosion resistance and easy cleaning. In combination with the fixed slide rail, ensure that the sample does not slide or tilt during rapid movement. | The top of the basket is standardly equipped with a Φ50mm test hole (Φ100mm, double-hole configuration is optional), with a silicone rubber sealing soft plug, which is convenient for powering on the test piece during the thermal shock test. |

|  |

Intelligent control system | Air Circulation System |

Touchable screen controller, supporting: 120 programs with 99-step Settings; Real-time operation curve, historical record, and alarm information display; RS232, USB and Modbus communication protocols, and can be remotely controlled and data exported. | Both the high-temperature zone and the low-temperature zone are equipped with high-power axial flow fans and forced air diversion structures to ensure that the temperature distribution uniformity inside the test chamber is within ±2.0℃. |

|  |

LIB thermal shock test machine, equipped with rapid response after-sales service, 3-year extended warranty and lifetime technical support. Consult LIB immediately and experience professional services!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español